1

VE416FS & VE416FSD

Read this first – Hazard Identification

Definitions for identifying the various hazard levels shown on warning labels or to indicate proper

safety procedures in this Manual are provided below.

This safety alert symbol indicates important safety messages on warning labels and in

this manual. When you see this symbol be alert to the possibility of personal injury and

carefully read and fully understand the message that follows.

The use of the word “WARNING” signifies the pres-

ence of hazards or unsafe practices which could

result in severe personal injury if instructions, in-

cluding recommended precautions, are not fol-

lowed.

NOTICE

The use of the word “NOTICE” signifies special

instructions which are important but not related to

hazards.

The use of the word “CAUTION” signifies possible

hazards or unsafe practices which could result in

minor injury, product or property damage if in-

structions, including precautions, are not fol-

lowed.

The use of the word “DANGER” always signifies an

immediate hazard with a likelihood of severe per-

sonal injury or death if instructions, including rec-

ommended precautions, are not followed.

INDEX

Hazard Identification . . . . . . . . . . . . . . . . . . . . . 1

Operator Safety Instructions. . . . . . . . . . . . . . . 2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Tool Set-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operating Tool . . . . . . . . . . . . . . . . . . . . . . . . 2

Tool Maintenance . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power Requirements . . . . . . . . . . . . . . . . . . . 3

Extension Cord Requirements . . . . . . . . . . . 4

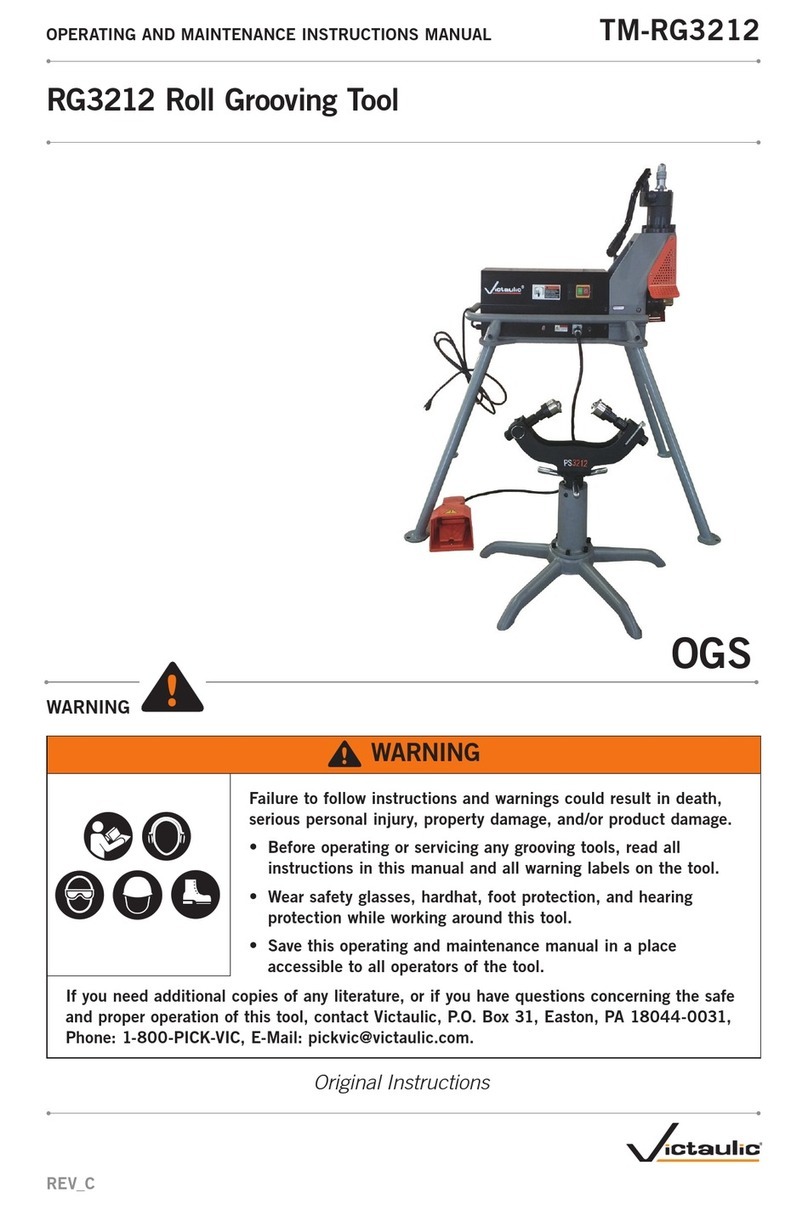

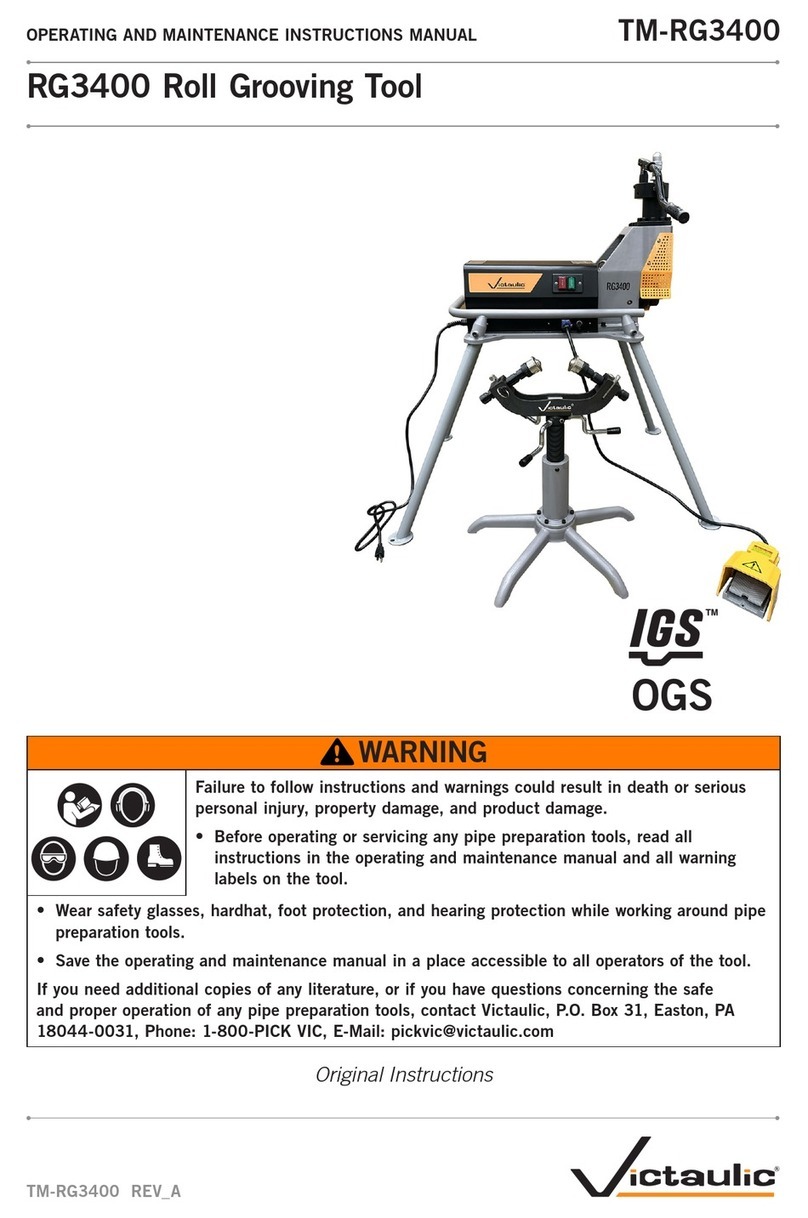

Tool Nomenclature. . . . . . . . . . . . . . . . . . . . . . . 5

Receiving Tool . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Tool Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pre-Operation Adjustments . . . . . . . . . . . . . . 10

Grooving Rolls . . . . . . . . . . . . . . . . . . . . . . . 10

Pipe Preparation . . . . . . . . . . . . . . . . . . . . . 10

Groovable Pipe Lengths . . . . . . . . . . . . . . . 11

Roll Guard Adjustment . . . . . . . . . . . . . . . . 13

Pipe Stabilizer Adjustment. . . . . . . . . . . . . 14

Groove Diameter Stop Adjustment . . . . . . 15

Grooving Operation . . . . . . . . . . . . . . . . . . . . . 17

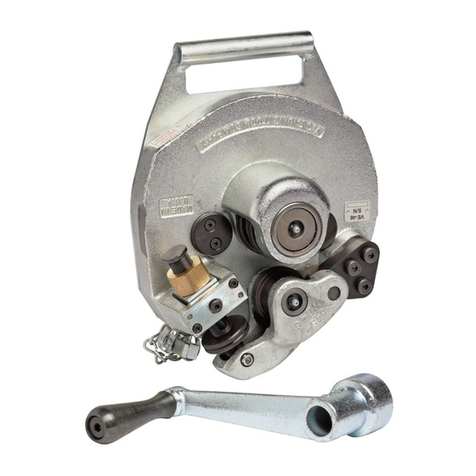

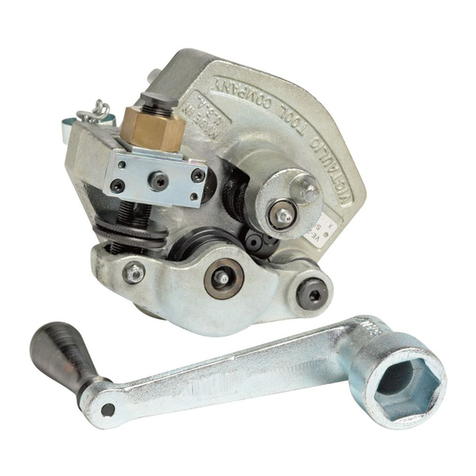

Roll Changing . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Roll Removal 4 - 16" . . . . . . . . . . . . . . . . . . . 20

Roll Installation 4 - 16" . . . . . . . . . . . . . . . . .21

Roll Installation 2 - 3

¹⁄₂

". . . . . . . . . . . . . . . . .22

Copper Roll Installation 2 - 6" and 8". . . . . . 23

Maintenance Procedures . . . . . . . . . . . . . . . . . 23

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Lubrication Monthly (VE416FSD Only). . . . 24

Hydraulic Systems . . . . . . . . . . . . . . . . . . . . 24

Parts Ordering Information. . . . . . . . . . . . . . . . 26

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . .28

Tool Rating and Roll Selection . . . . . . . . . . . . . 29

Standard and “ES” Rolls . . . . . . . . . . . . . . . .29

Schedule 5S and 10S Stain. Steel Pipe . . . .30

Copper Tubing . . . . . . . . . . . . . . . . . . . . . . .30

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Seamless and Welded Steel Pipe. . . . . . . . . 31

Drawn Copper Tubing . . . . . . . . . . . . . . . . . 31

Roll Groove Specifications . . . . . . . . . . . . . . . .32

Steel Pipe and all Materials Grooved

with Standard and “RX” Rolls . . . . . . . . . 32

Steel Pipe and all Materials Grooved

with “ES” Rolls. . . . . . . . . . . . . . . . . . . . . . 33

Drawn Copper Tubing w/Copper Rolls . . . .34

® Registered Trademark of Victaulic Company of America

© Copyright 1997 Victaulic Company of America Printed in U.S.A.