-4-

Operating Instructions

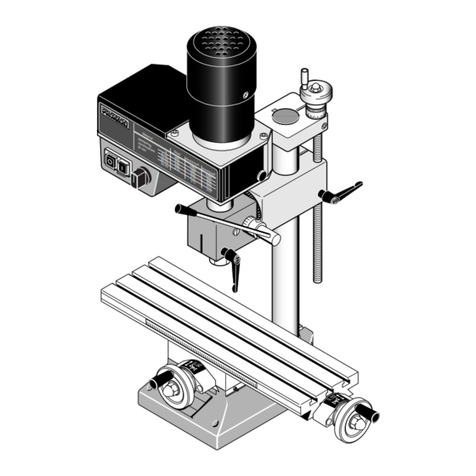

MT 300

Instructions for the use of the MICRO Shaper

MT 300:

Dear Customer,

In order tobeable to operatethe shaper safely and

correctly,pleasecarefully readthe following safety and

operating instructions prior touse.

This instruction manualcovers:

•safety regulations

•operation and maintenance

•spare parts list

Pleasereadcarefully and become familiar withthis

entire instructions manual. Learnthe tool´s applications,

limitations and possible hazards.

Using this instruction manualwill

•make it easier for you to get used tothe machine,

•help prevent faults occurring dueto improper useand

•increasethe service life of your machine.

Keep this instruction manual in an easily accessible

place. Only operatethis machine if you are qualified to

do soand follow the guidelines in this instruction

manual.

PROXXON does not accept responsibility for the safe

functioning of the machine

•if it is handled in amanner whichconstitutes improper

use,

•if it is used for other purposes whichare not specified

in the instruction manual,

•if the safety regulations are not observed.

Warranty claims are invalid if

•the machine is incorrectly operated,

•the machine has not been sufficiently maintained.

Inthe interests of your safety,pleasealways observe

the safety regulations.

Only use genuine PROXXON spare parts.

Wereservethe right to make further alterations for the

purpose of technical progress.

Wewishyou every success withyour machine.

Safety instructions

1. KEEP GUARDS IN PLACE and in working order.

2.REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking tosee that keys and

adjusting wrenches areremoved from tool before

turning it on.

3.KEEP WORK AREA CLEAN.Cluttered areas and

benches inviteaccidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations,or

exposethem torain. Keep workareawell lighted.

5. KEEP CHILDREN AWAY.All visitors should be kept

safe distance from workarea.

6.MAKE WORKSHOP KID PROOF with padlocks,

master switches,or by removing starter keys.

7.DON’T FORCE TOOL.It will do the job better and

safer at the rate for which it was designed.

8. USE RIGHT TOOL.Don’t forcetool or attachment

to do ajobfor which it was not designed.

9. USE PROPER EXTENSION CORD.Make sure

your extension cord is in good condition. When

using an extension cord, besuretouse one heavy

enough tocarry the current your product will draw.

Anundersized cordwill causeadrop in line voltage

resulting in loss of power and overheating. Table 1

shows the correct sizetouse depending on cord

lengthand nameplateampererating. If in doubt,

usethe next heavier gage. The smaller the gage

number,the heavier the cord.

10.WEAR PROPER APPAREL.Do not wear loose

clothing,gloves,neckties,rings, bracelets,or other

jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering tocontain long hair.

Exception: The referenceto gloves may be omitted

from the instructions for agrinder.

11. ALWAYS USE SAFETY GLASSES.Alsouse face or

dust mask if cutting operation is dusty.Everyday

eyeglasses only have impact resistant lenses,they

areNOT safety glasses.

12.SECURE WORK.Useclamps or aviseto hold work

when practical. It’s safer thanusing your hand and it

frees both hands to operatetool.

13.DON’T OVERREACH.Keep proper footing and

balanceat all times.

14. MAINTAIN TOOLS WITH CARE.Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing

accessories.

15. DISCONNECT TOOLS beforeservicing; when

changing accessories,suchas blades, bits, cutters,

and the like.

16.REDUCE THE RISK OF UNINTENTIONAL

STARTING.Make sureswitch is in off position

before plugging in.

17.USE RECOMMENDED ACCESSORIES.Consult

the owner’s manual for recommended accessories.

The use of improper accessories may causerisk of

injury to persons.

18. NEVER STAND ON TOOL.Serious injury could

occur if the tool is tipped or if the cutting tool is

unintentionally contacted.