6

Note

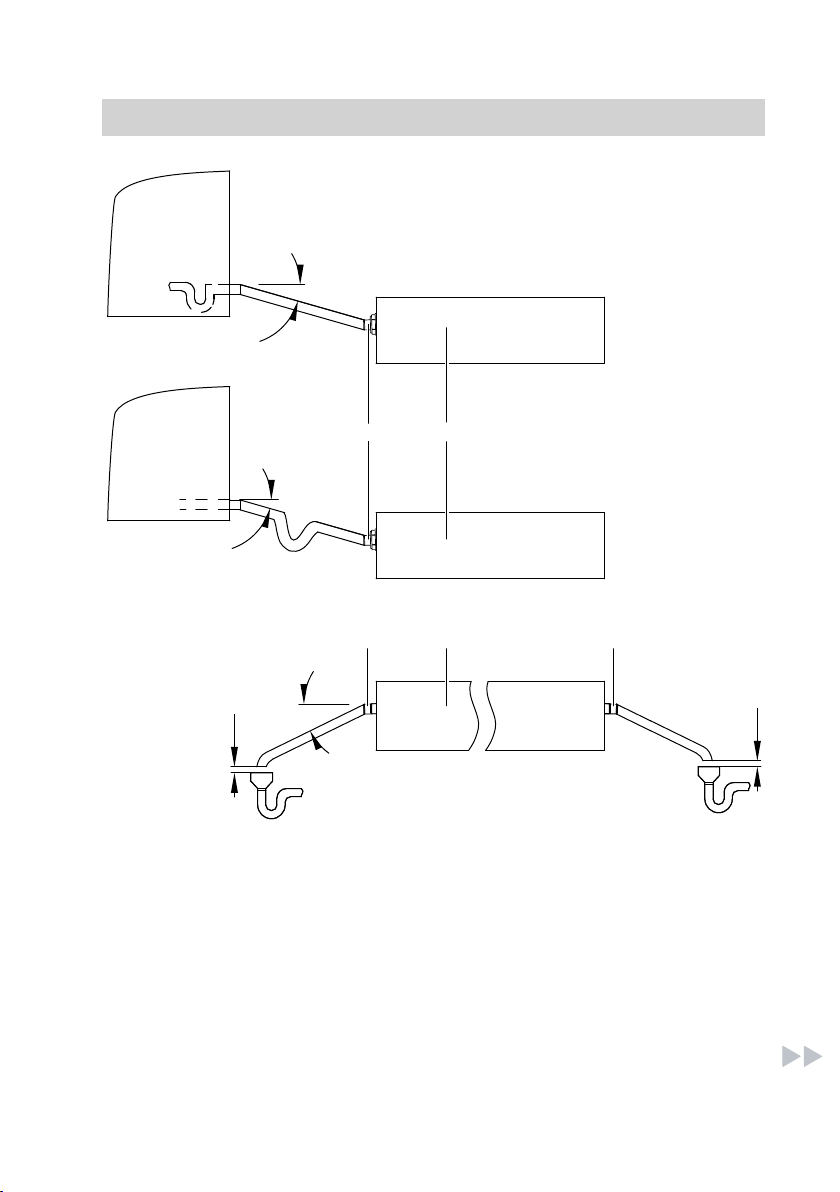

■ If the heat source does not have

a siphon, the supply hose must

be routed in a U-bend.

■ Never step on the hose. Protect

the hose against mechanical

damage.

3. Route the drain hose from the neu-

tralising system to the drainage

system with a fall. Secure the hose

with hose clips.

Note

■ Never connect the drain hose

directly to the sewage system. To

avoid retrograde bacterial con-

tamination from the sewage sys-

tem, observe the minimum clear-

ance of 20 mm (see diagram).

■ Never step on the hose. Protect

the hose against mechanical

damage.

Commissioning and adjustment

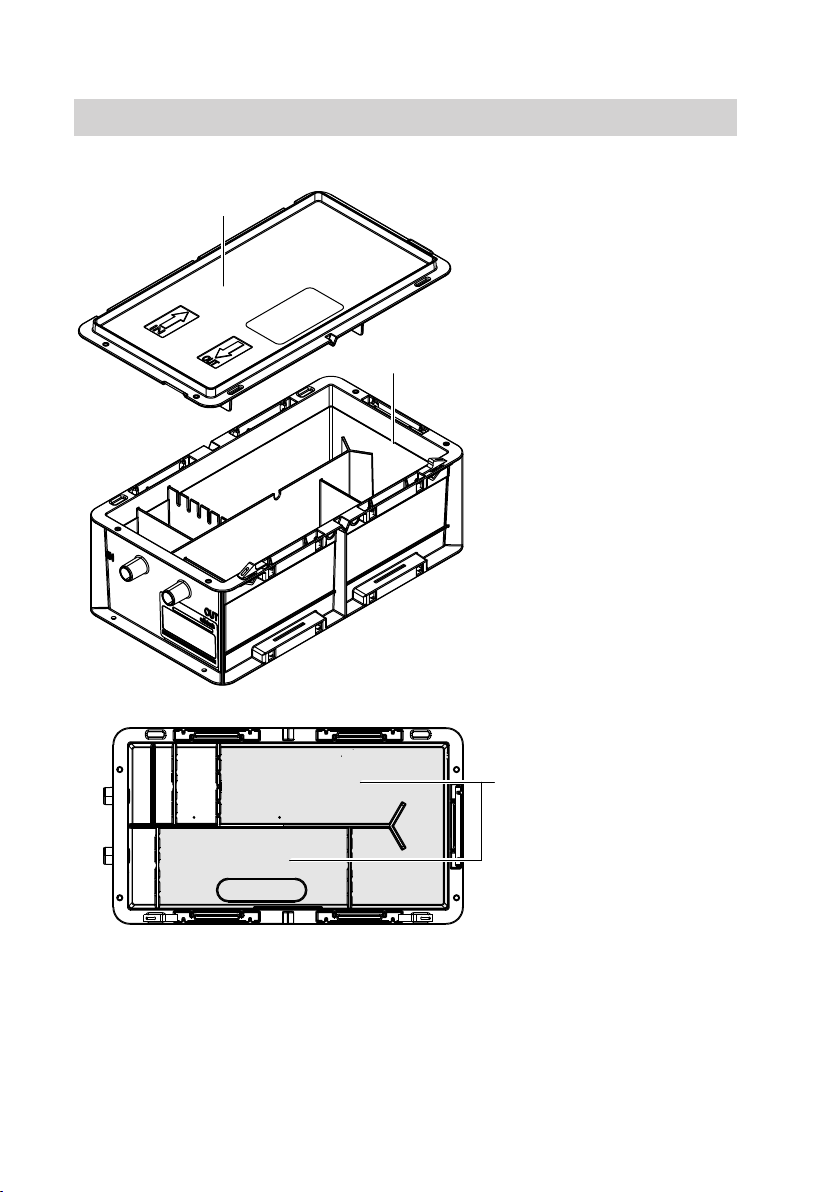

1. Remove the neutralising system

cover.

2. For part no. 7437829: Assemble

the slot-together casing. The size of

the fill area for neutralising granu-

late can be determined subject to

the condensate level (see

page 10).

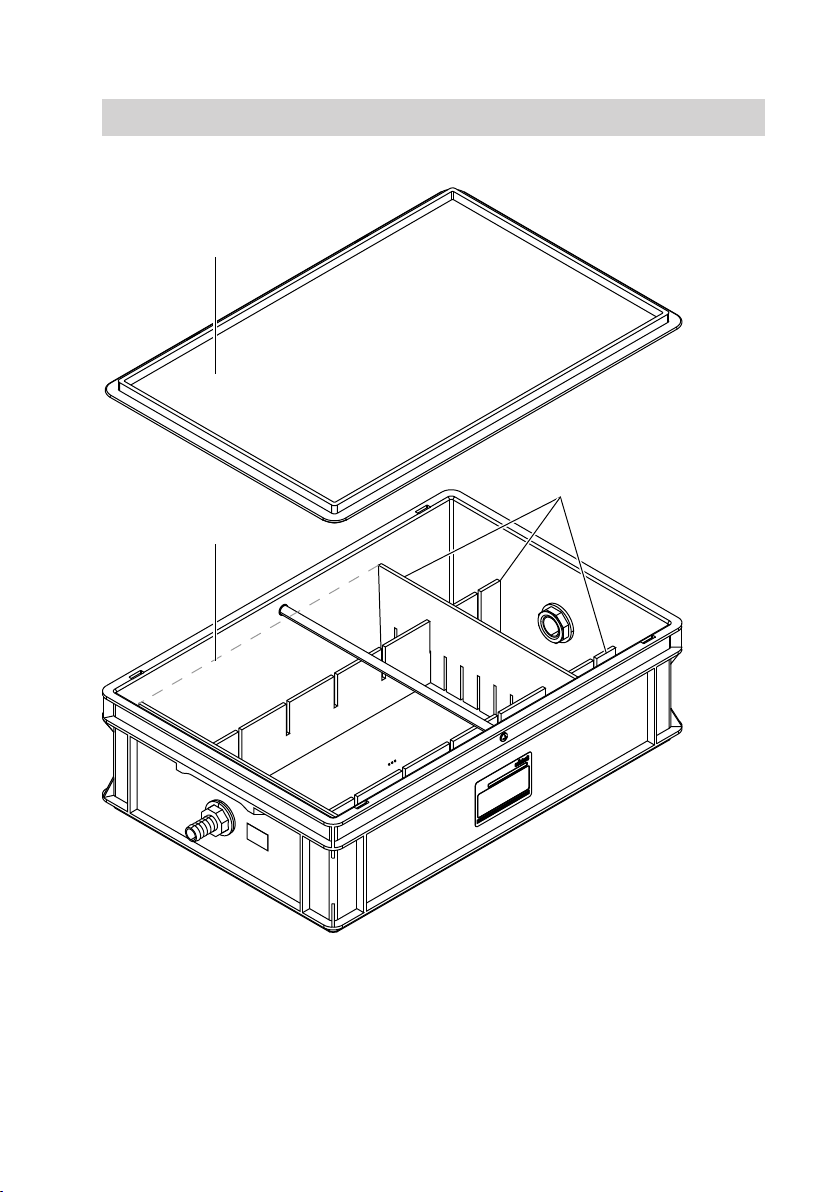

3. Fill the relevant area with neutralis-

ing granulate (see pages 8

to 10).

4. Fill the neutralising system with

water.

5. Check the container and the supply

and drain lines for leaks.

6. Close the neutralising system

cover.

7. Start the heat source.

8. Record commissioning on

page 17.

Note

During commissioning, instruct the sys-

tem user in the operation of the appli-

ance.

Positioning and connecting (cont.)

5601311