9

5728 556 v1.0

Vitotronic 100, KW10A Operating and User’s Information Operation

Service Notice for your Heating System

Additional Safety Requirements

WARNING

The are no user-serviceable components on the boiler,

burner, control or on the heating system. Contact a

qualified heating contractor for service!

CAUTION

Ensure the mechanical room and the hot water heating

boiler itself, is kept clean.

WARNING

Failure to protect against frozen pipes could result in burst

water pipes, serious property damage and/or personal

injury. Boiler may shut down. Do not leave your home

unattended for long periods of time during freezing

weather conditions without turning off the water supply

and draining water pipes or otherwise protecting against

the risk of frozen pipes.

We strongly recommend that you have your heating system checked and serviced by a qualified heating contractor on

an annual basis to ensure a safe and energy efficient operation.

A service contract is advisable.

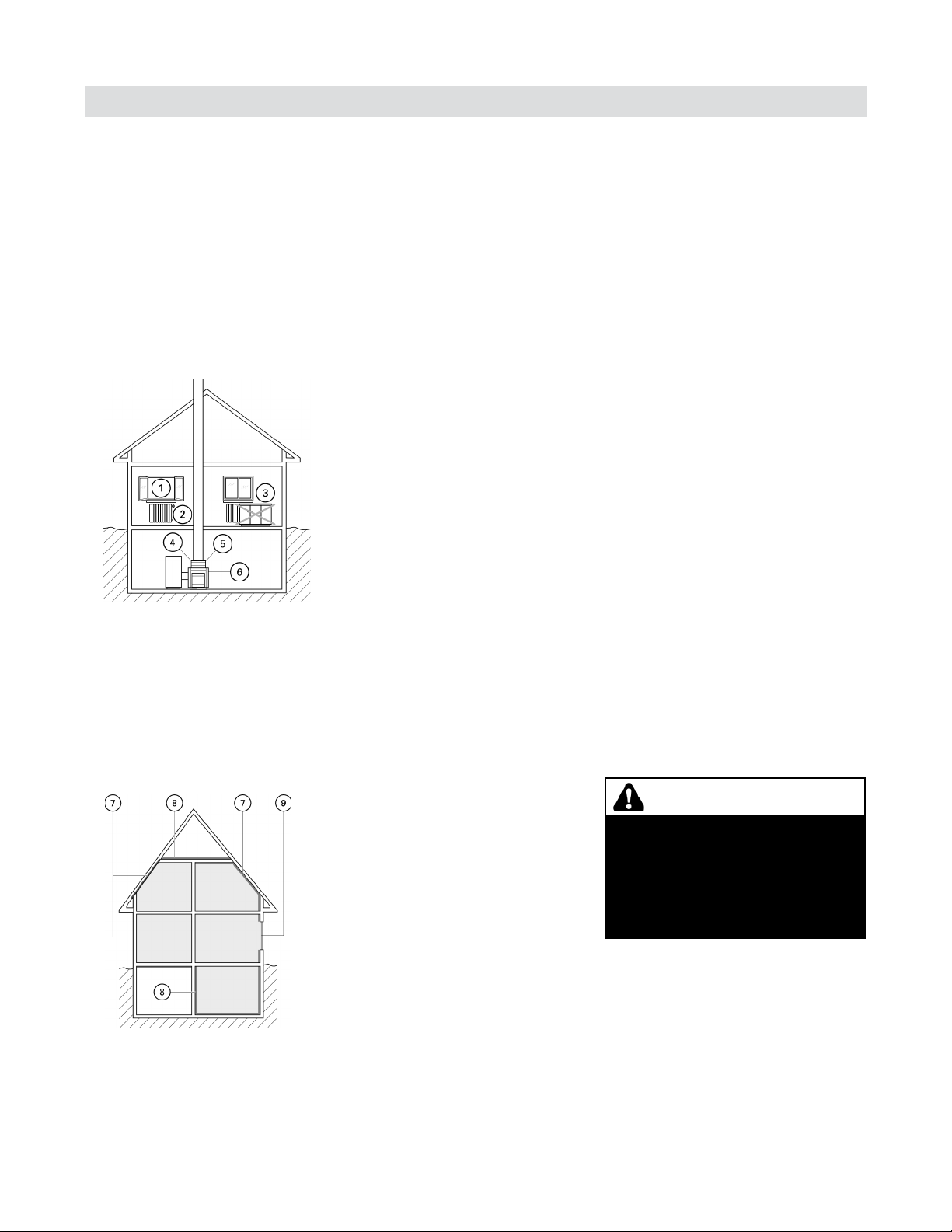

Boiler

Every boiler must be cleaned within certain time frames.

A lack of cleaning causes soot build-up in the combustion

chamber which raises the flue gas temperature and

reduces the efficiency of your heating system.

System

Ensure that a qualified heating contractor checks all

system components such as the expansion tank, the

pressure relief valve, the pump(s), the zone valves, the

low water cut-off and all other system componentry

regularly.

Carbon monoxide

The U.S. Consumer Product Safety Commission strongly

recommends the installation of carbon monoxide detectors

in buildings in which gas-burning equipment is installed.

Carbon monoxide (CO) is a colorless, odorless gas, which

may be produced during incomplete combustion of fuel

and/or when the flame does not receive an adequate

supply of combustion air.

Carbon monoxide can cause severe personal injury or loss

of life.

Therefore, carbon monoxide detectors that are in

compliance with a nationally recognized standard (e.g.

ANSI/UL 2034-2002, CSA 6.19-01) should be installed

and maintained in buildings that contain gas-burning

equipment.

Note: Viessmann does not test any detectors and makes

no representation regarding any brand or type of

detector.

Frozen water pipe hazard

Your heating boiler is designed to provide a warm and

comfortable living environment. It is NOT designed to

ensure against freezing of water pipes.

The boiler is equipped with several safety devices that

are designed to shut down the boiler and to prevent it

from restarting in the event of various unsafe conditions.

If your boiler remains off for an extended period of time

during cold weather, water pipes may freeze and burst,

resulting in extensive water damage and conditions in

which mold could grow. Certain molds are known to

cause respiratory problems, as well as to pose other

serious health risks. In case of water damage, immediate

measures should be taken to dry out affected areas as

quickly as possible to prevent mold from developing.

If your home will be unattended for an extended period of

time during cold weather, you should...

Shut off the water supply to the building, drain the water

pipes and add an antifreeze for potable water to drain

traps and toilet tanks. Open faucets where appropriate.

or

Have someone check the building frequently during cold

weather and call a qualified service agency if required.

or

Install a reliable remote temperature sensor that will notify

somebody of freezing conditions within the home.