2

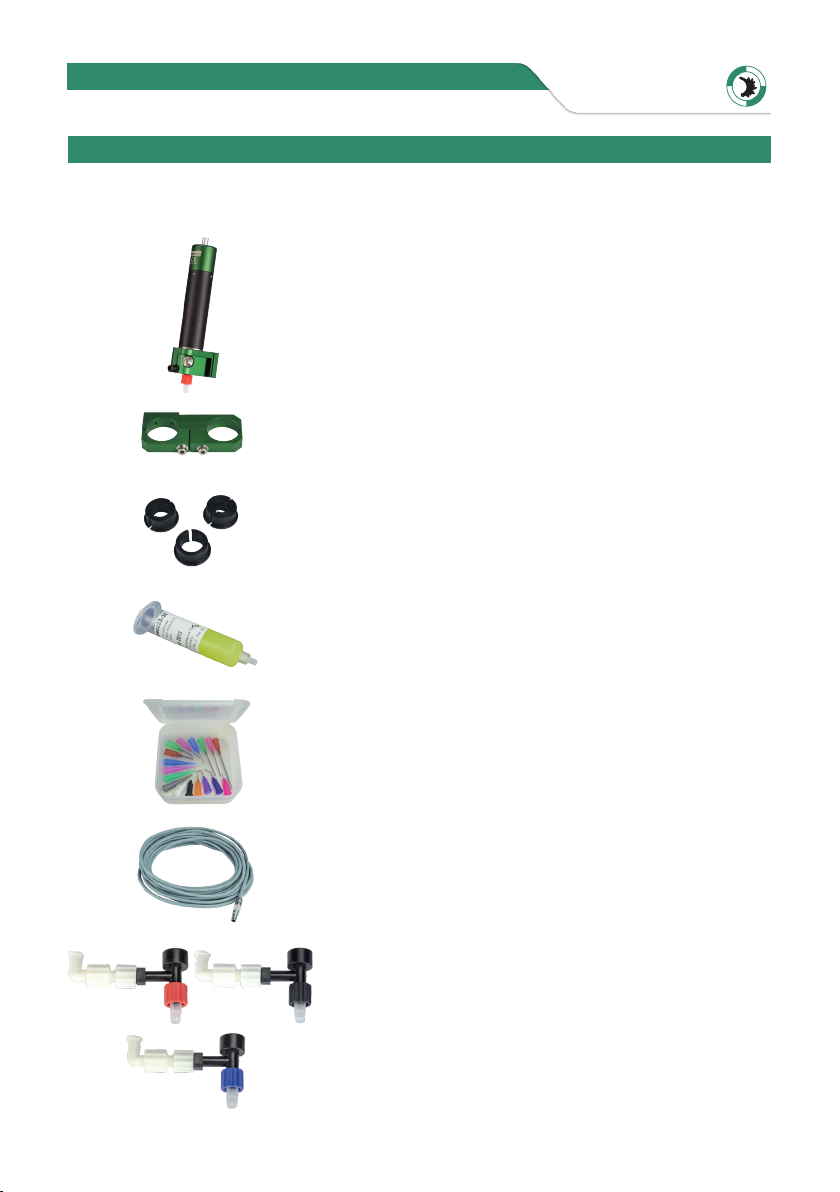

Manual Screw Valve DV-5005DFS /-L

Table of contents

1 Designated use

Dear Customer

Thank you for purchasing the screw valve DV-5005DFS.

For easy operating we developed this user manual.

Your Vieweg Team

The spindle valve DV-5005DSF is a revolutionary further development of conventional

spindle valves in order to solve the problems occurring there. Two-component material

is always a special challenge. Above all because it can completely destroy the valve by

hardening. Just as abrasive materials lead to high wear in the shortest possible time.

With the exchangeable material spindle, all these problems could be solved.

The precisely manufactured plastic spindle can be replaced quickly and easily. Cleaning

the valve is considerably simplified and is now no longer a time-consuming process.

No more expensive spare valves have to be in stock to keep lines running.

Replacement spindles are completely sufficient for this.

1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

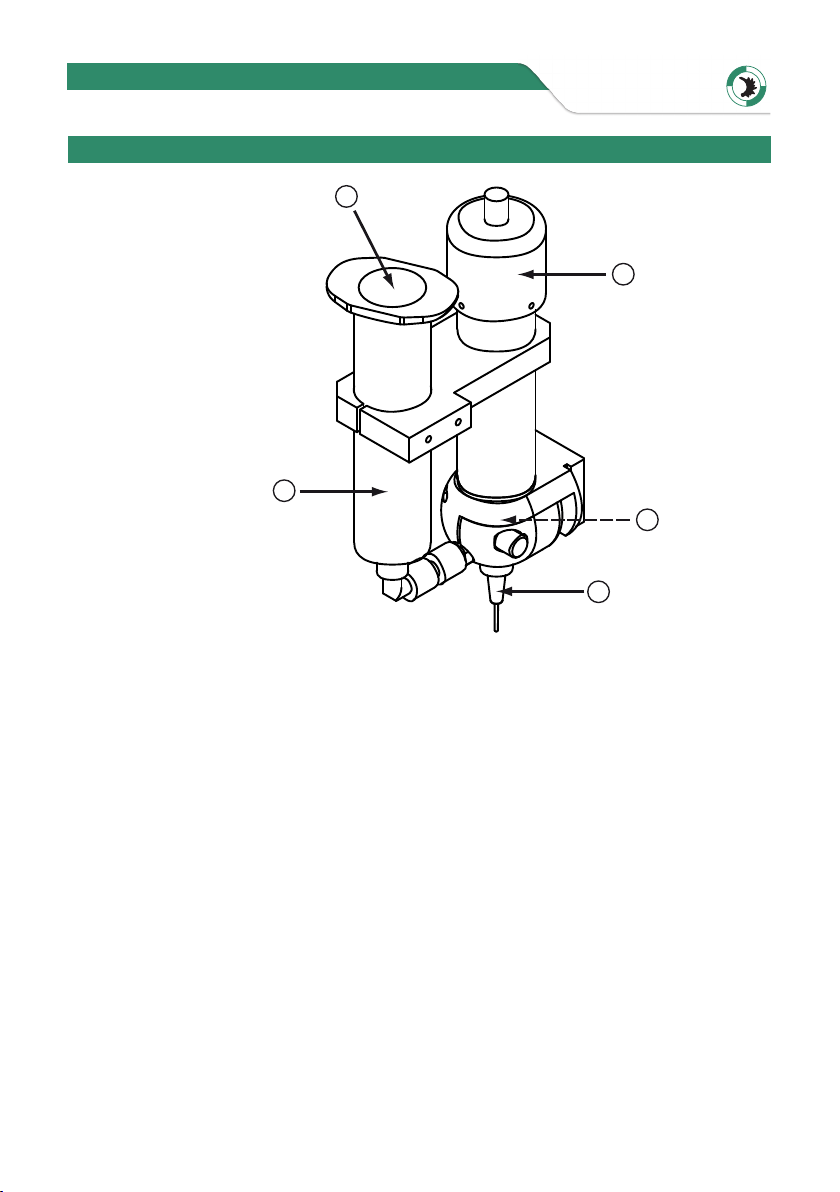

4 Part list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

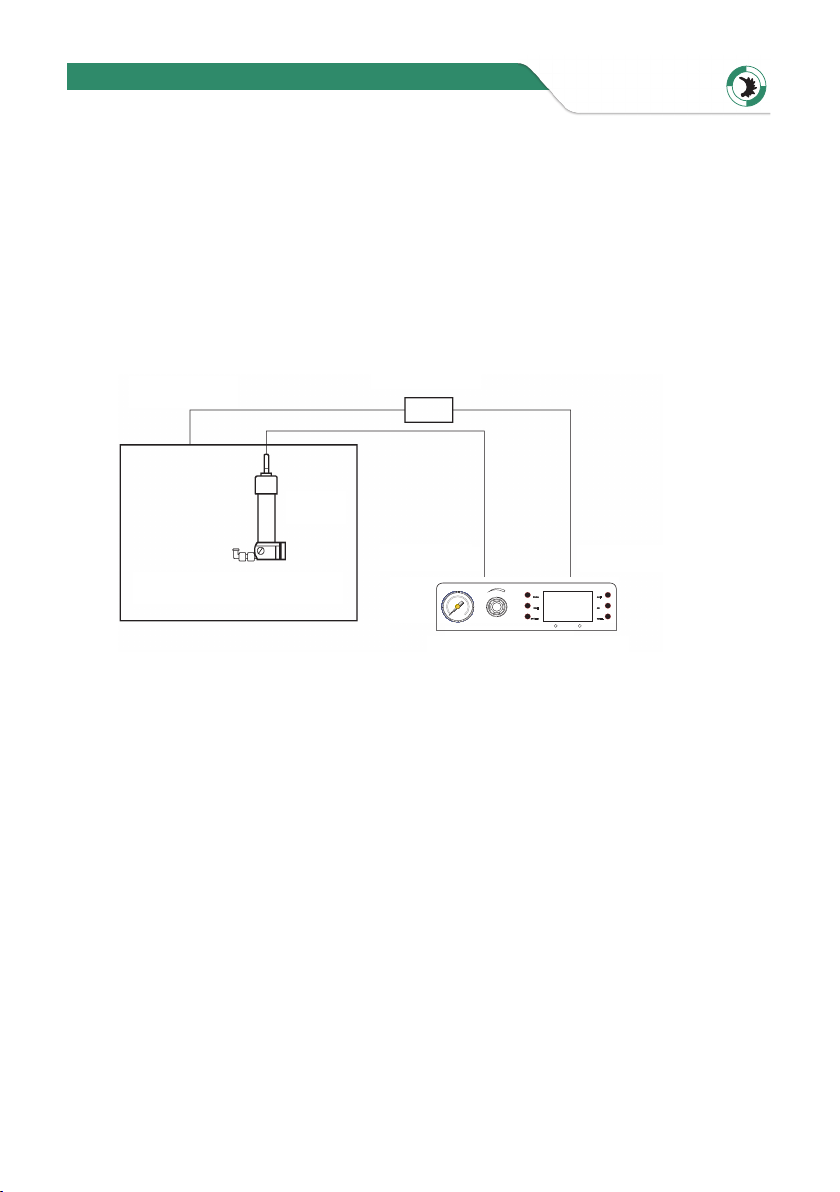

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.1 Mechanical mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.2 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.3 Compressed air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.1 Fill spindle with material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.2 Installation of a new disposable spindle . . . . . . . . . . . . . . . . . . . . . . 10

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10