2

NNOOTTEE::IIFFIINNSSTTAALLLLIINNGGHHOOOODDWWIITTHH

WWAARRMMIINNGGSSHHEELLFFPPAANNEELL,,IINNSSTTAALLLL

WWAARRMMIINNGGSSHHEELLFFPPAANNEELLFFIIRRSSTT..

IIMMPPOORRTTAANNTT--

PPLLEEAASSEERREEAADDAANNDDFFOOLLLLOOWW

•Before beginning, please read these instructions

completely and carefully.

•Do not remove permanently affixed labels, warnings, or

plates from the product. This may void the warranty.

•Please observe all local and national codes and

ordinances. If no local codes are applicable, wire in

accordance with the National Electrical Code,

ANSI/NFPA 70-1990.

••CChheecckkwwiitthhaaqquuaalliiffiieeddaannddttrraaiinneeddiinnssttaalllleerroorrllooccaall

ccooddeessffoorrmmaakkeeuuppaaiirrrreeqquuiirreemmeenntt,,iiffaannyy..

•TThheeiinnssttaalllleerrsshhoouullddlleeaavveetthheesseeiinnssttrruuccttiioonnsswwiitthhtthhee

ccoonnssuummeerrwwhhoosshhoouullddrreettaaiinnffoorrllooccaalliinnssppeeccttoorr’’ssuusseeaanndd

ffoorrffuuttuurreerreeffeerreennccee..

This hood is for residential installation only and is not

designed for installation over a commercial product.

Make sure power is off at the main circuit breaker or fuse

box before making connections. TTooaavvooiiddrriisskkooffffiirree,,

eelleeccttrriiccsshhoocckk,,oorriinnjjuurryyttooppeerrssoonnss,,ttuurrnnoofffftthheeeelleeccttrriicciittyy

ttootthheehhooooddffrroommtthheeppoowweerrssuuppppllyybbeeffoorreesseerrvviicciinnggoorr

cclleeaanniinngg..

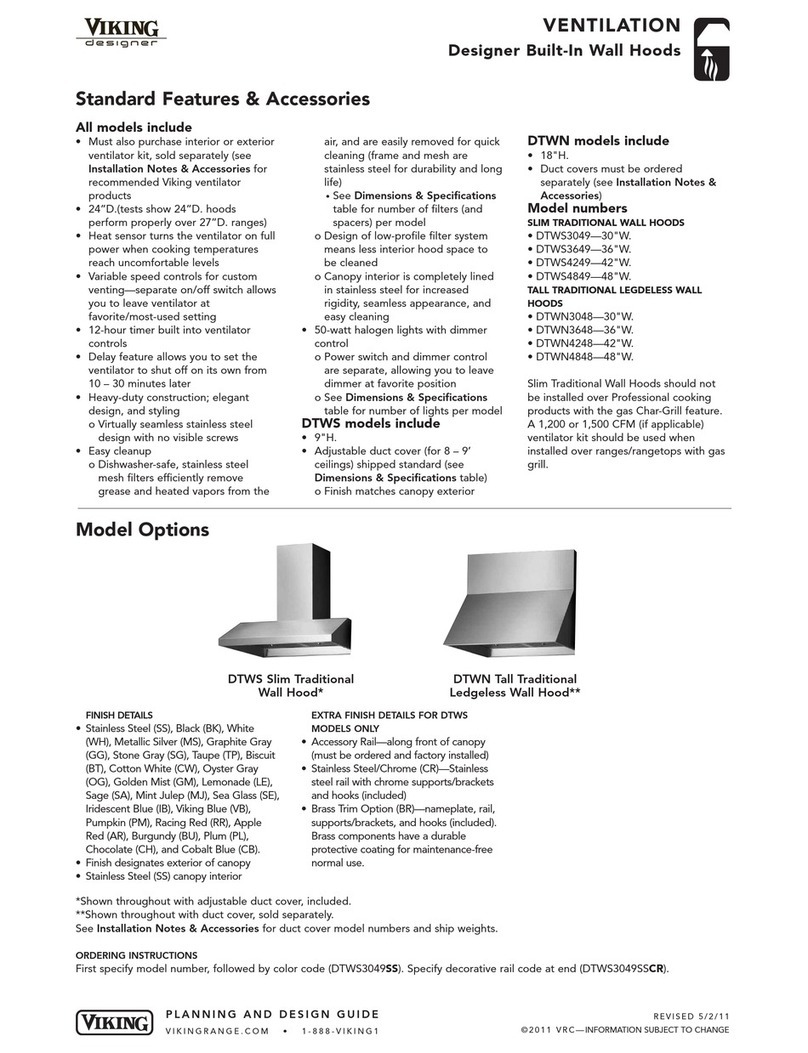

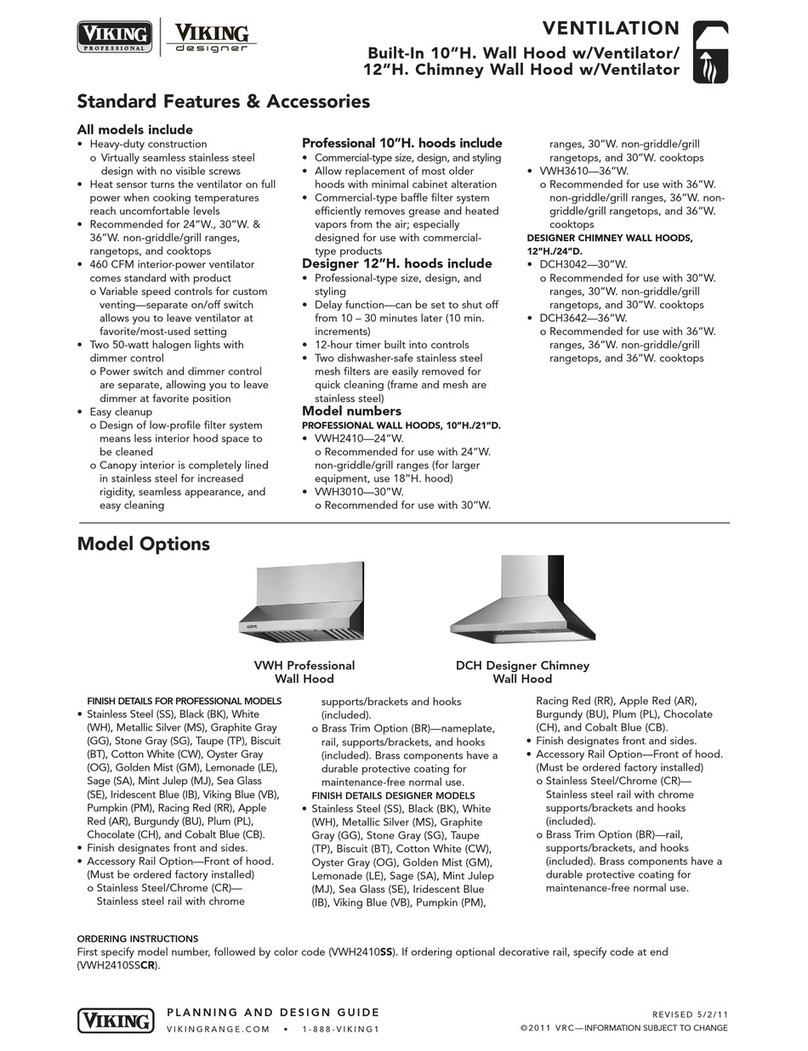

Viking Range hoods are equipped with variable speed

controls for blowers. These units will not function with a

single

speed ventilator. All Viking Range ventilator kits are

designed specifically for use with Viking Range hoods.

Use of

any non-Viking Range ventilator kit will void the hood

warranty.

WWAARRNNIINNGG

TTOORREEDDUUCCEETTHHEERRIISSKKOOFFFFIIRREE,,EELLEECCTTRRIICCAALLSSHHOOCCKK,,

OORRIINNJJUURRYYTTOOPPEERRSSOONNSS,,OOBBSSEERRVVEETTHHEEFFOOLLLLOOWWIINNGG::

1. Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction.

2. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent back drafting. Follow

the heating equipment manufacturer’s guideline and

safety standards such as those published by the

National Fire Protection Association (NFPA), and the

American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code

authorities.

3. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

4. Ducted fans must always be vented to the outdoors.

5. WWAARRNNIINNGG!!::To reduce the risk of fire, use only metal

ductwork.

6. CCAAUUTTIIOONN!!::To reduce risk of fire and to properly

exhaust air, be sure to duct air outside. Do not vent

exhaust air into spaces within walls or ceilings, or into

attics, crawl spaces, or garages.

CCAAUUTTIIOONN

For general ventilating use only. Do not use

to exhaust hazardous or explosive materials

and vapors.

WWAARRNNIINNGG

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK,

OR INJURY TO PERSONS, RANGEHOODS MUST BE

INSTALLED WITH THE VENTILATORS THAT ARE

SPECIFIED ON THEIR CARTON INDICATING

SUITABILITY WITH THIS MODEL. OTHER VENTILATORS

CANNOT BE SUBSTITUTED.

WWAARRNNIINNGG

TTOORREEDDUUCCEETTHHEERRIISSKKOOFFAARRAANNGGEETTOOPPGGRREEAASSEE

FFIIRREE::

1. Never leave surface units unattended at high

setting. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on

low or medium settings.

2. Always turn hoon ON when cooking at high

heat or when cooking flaming foods.

3. Clean ventilating fans frequently. Grease should

not be allowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware

appropriate for the size of the surface element.