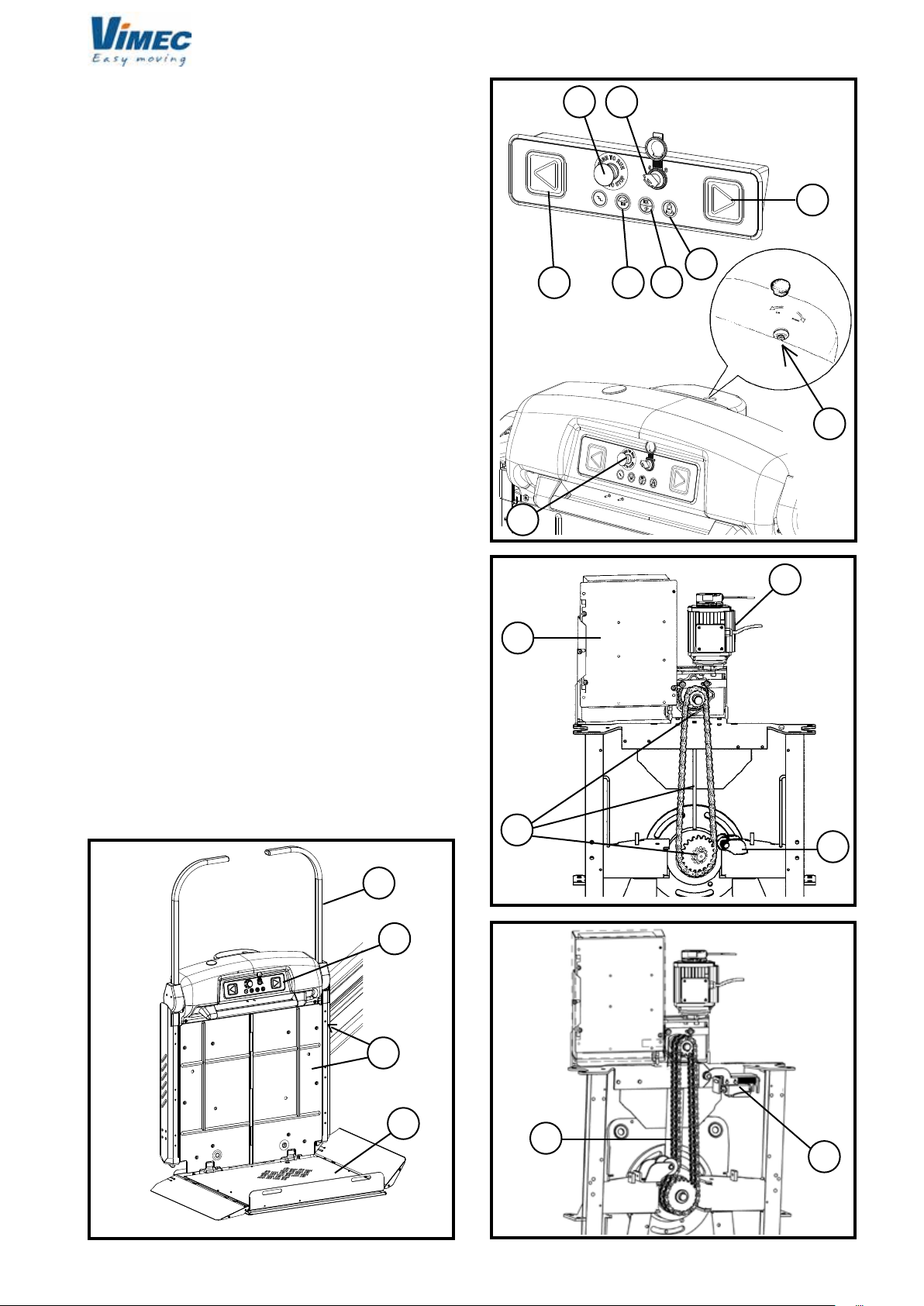

10

ab

a

c

d

b

a

7511131

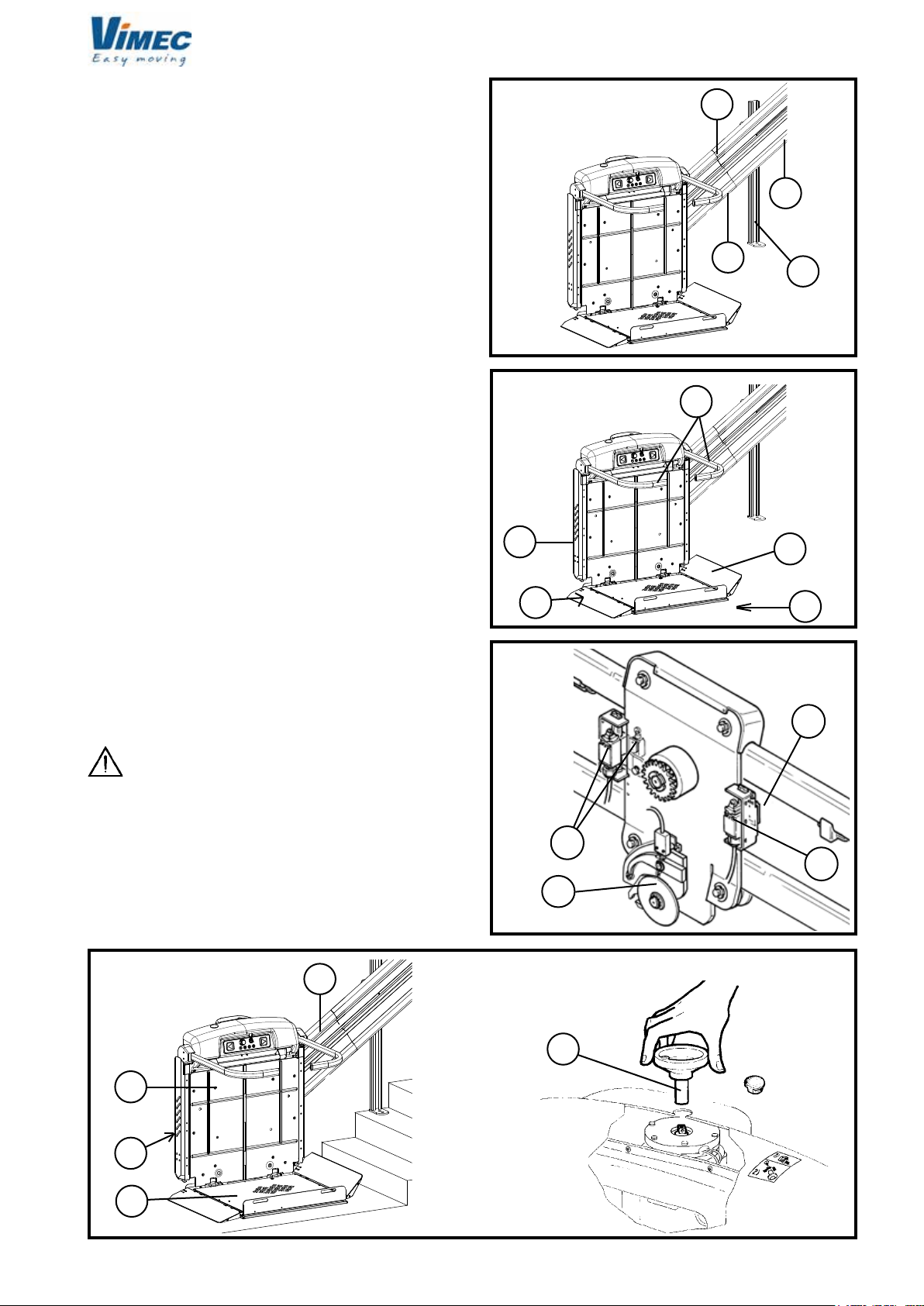

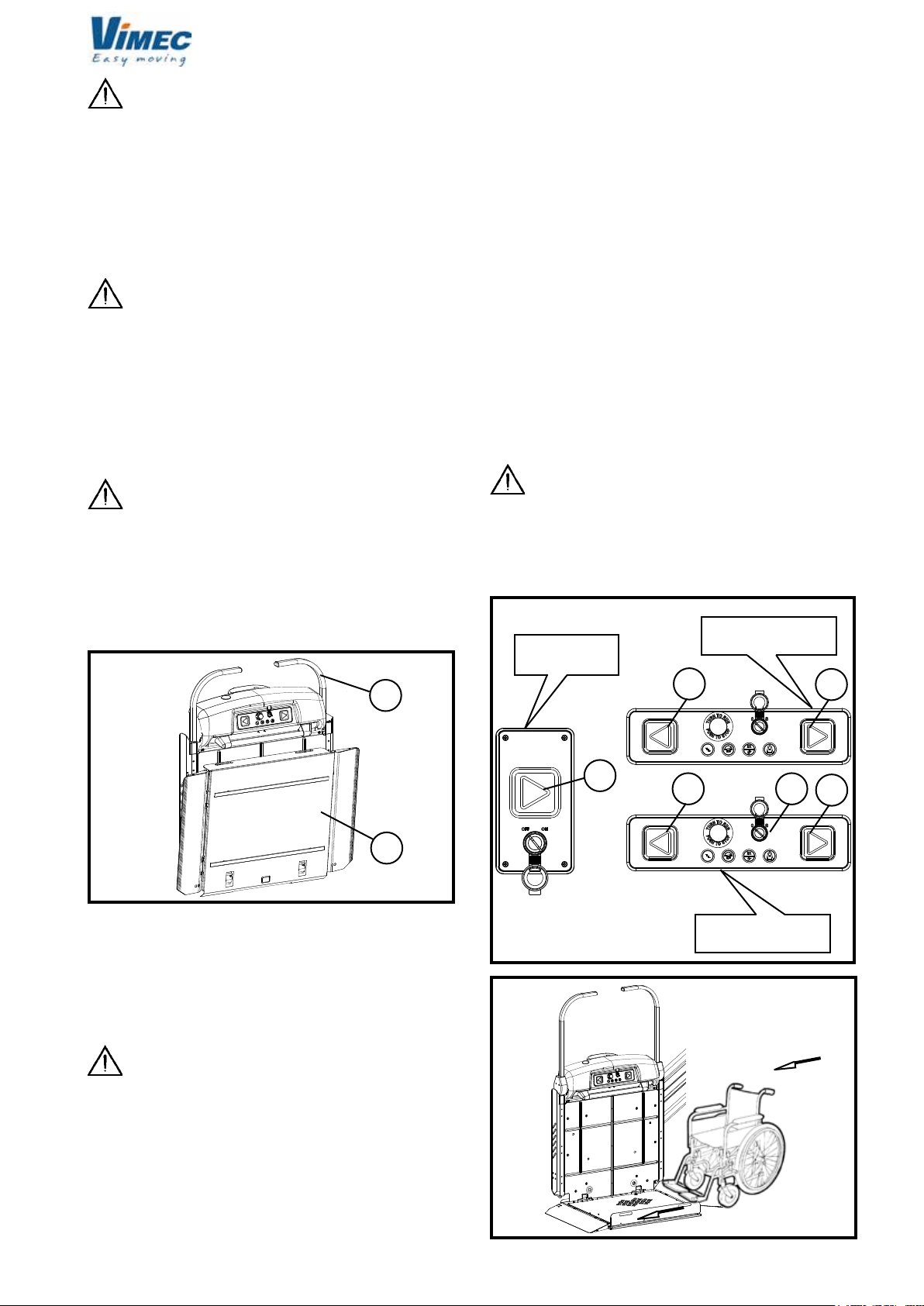

4) Press the up button (Fig. 9/c); the guards and bars

automatically move to the safety position and the stai-

rlift sets off.

5) B.R. - B.I. Version. At the destination oor, the stairlift

stops; if the up button is kept pressed, the bars and the

guard facing in the up direction automatically move to

the drive-off position. The guard facing in the down

direction is locked in the safety position, to ensure the

wheelchair can leave and return to the stairlift in safety.

6) Azionando il pulsante di discesa (Fig.9/b) le barre

e la bandella rivolta verso la salita si dispongono in

posizione di sicurezza e la macchina parte.

7) Al piano di arrivo la macchina si ferma e tenendo

premuto il pulsante di discesa (Fig.9/b) le barre e le

bandelle automaticamente si dispongono in posizione

di sbarco.

8) Disporre la macchina nelle condizioni di partenza

(con pedana chiusa e barre in posizione di riposo)

(Fig.8) disinserire ed estrarre la chiave.

N.B: Le barre e le bandelle sono meccanicamente

bloccate per tutto il percorso tra i piani.

WARNING: Pressing two buttons simulta-

neously, whether on the board on the stairlift or the

board at the oor, is strictly prohibited.

WARNING: The person transported must

always remain in the recommended position, with

the wheelchair brakes on, if the wheelchair is elec-

tric, turn it off, as long as transport is in progress.

The feet must be kept on the wheelchair foot-rest

and the free hand on one of the platform handle

(Fig. 11/c).

WARNING: The person transported must

always look in the travel direction and must stop

the stairlift immediately if there is anyone on the

travel route.

WARNING: During operation of the stairlift

the landings and travel route must always be illu-

minated (minimum 50 Lux measured at oor level).

WARNING: Use of the stairlift by unau-

thorised persons is not permitted. The key which

enables use of the stairlift must always be kept in

a safe place and access to it may only be permitted

to authorised persons. The key must always be

removed at the end of each trip. Leaving the key

always in place is not permitted.

WARNING: Never leave the platform halfway

up the staircase.

ATTENZIONE: Never use the stairlift unless

a trained person is available to operate it in manual

mode in an emergency.

ATTENZIONE: Never place your hands or

any objects close to the rails or platform while the

stairlift is in motion.

ATTENZIONE: If the machine is installed

outside, cover it with a protection cloth after using

it. Remove the keys from the push-button panel and

close the rubber lid (Fig. 9/a).

Note for motor-operated platform

The device makes it possible to upset the platform by

an actuator.

The platform may be opened and closed by pressing

the button on the control board at the oor (Fig. 9/d).

A special manual device makes it possible to close the

platform in case of emergency:

1) Push the release button (located on the front body

towards the descent side) (Fig. 12/a) paying attention

to make a light pressure on the platform to avoid a

suddenly shutting.

2) Pull the platform gently, until the complete shutting.

3) Reset the normal functions of the equipment after

the emergency by a manual complete opening of the

platform.

WARNING: In the B.R. - B.I. Version, the

platform can only be operated with the down side

bar in the working position.

N.B: If the button on the control board at the oor

FIG.11

FIG.12

7512131