6

7502050

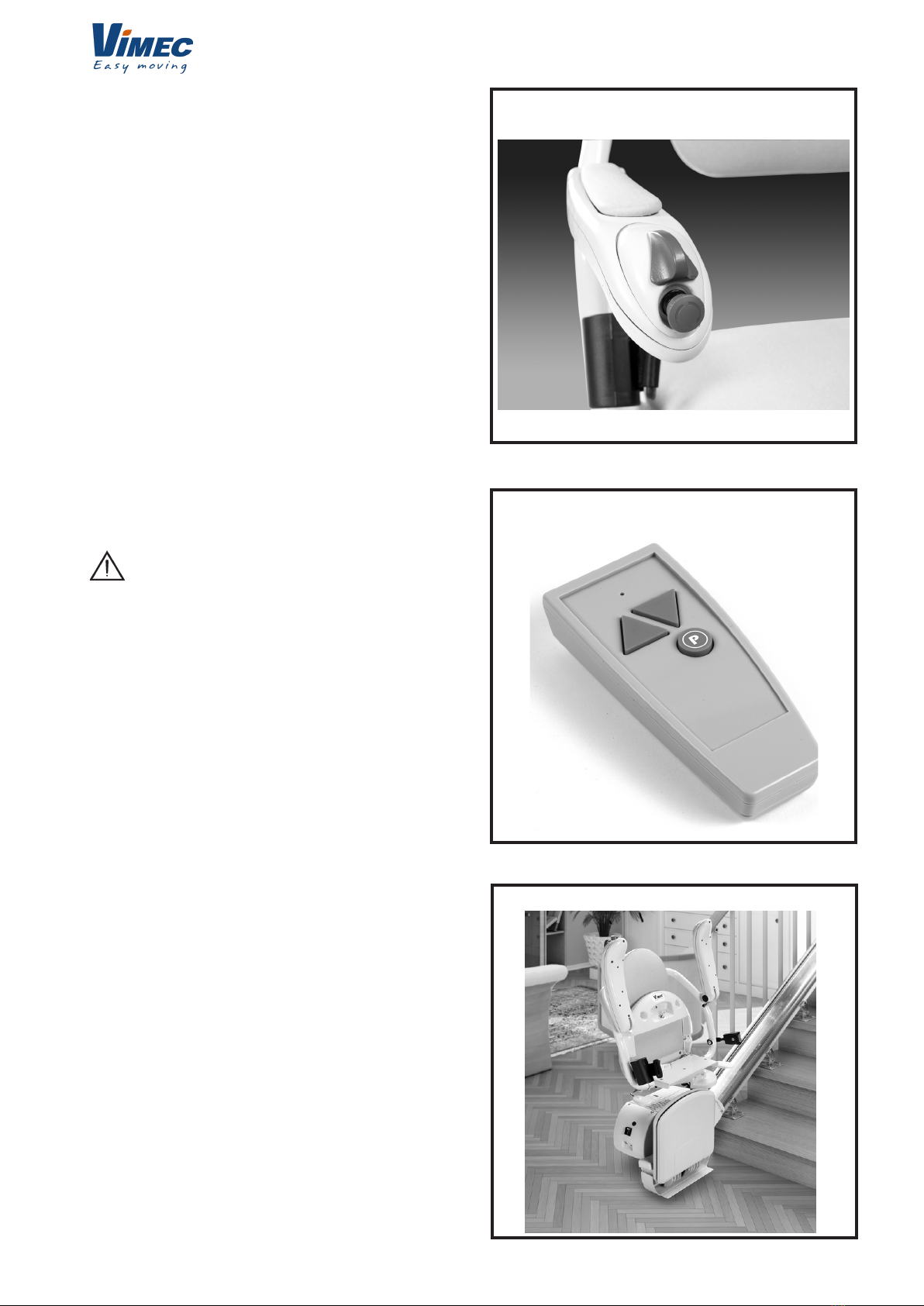

To operate the seat swivel, wait until the stairlift

has stopped.

To swivel the seat hold the swivel lever down (Fig.

8). When the seat reaches 90 degrees it will lock in

position.

You should not attempt to leave the seat until it has

rmly ‘clicked’ into its locked position (Fig. 9).

To swivel in the opposite direction follow the same

procedure.

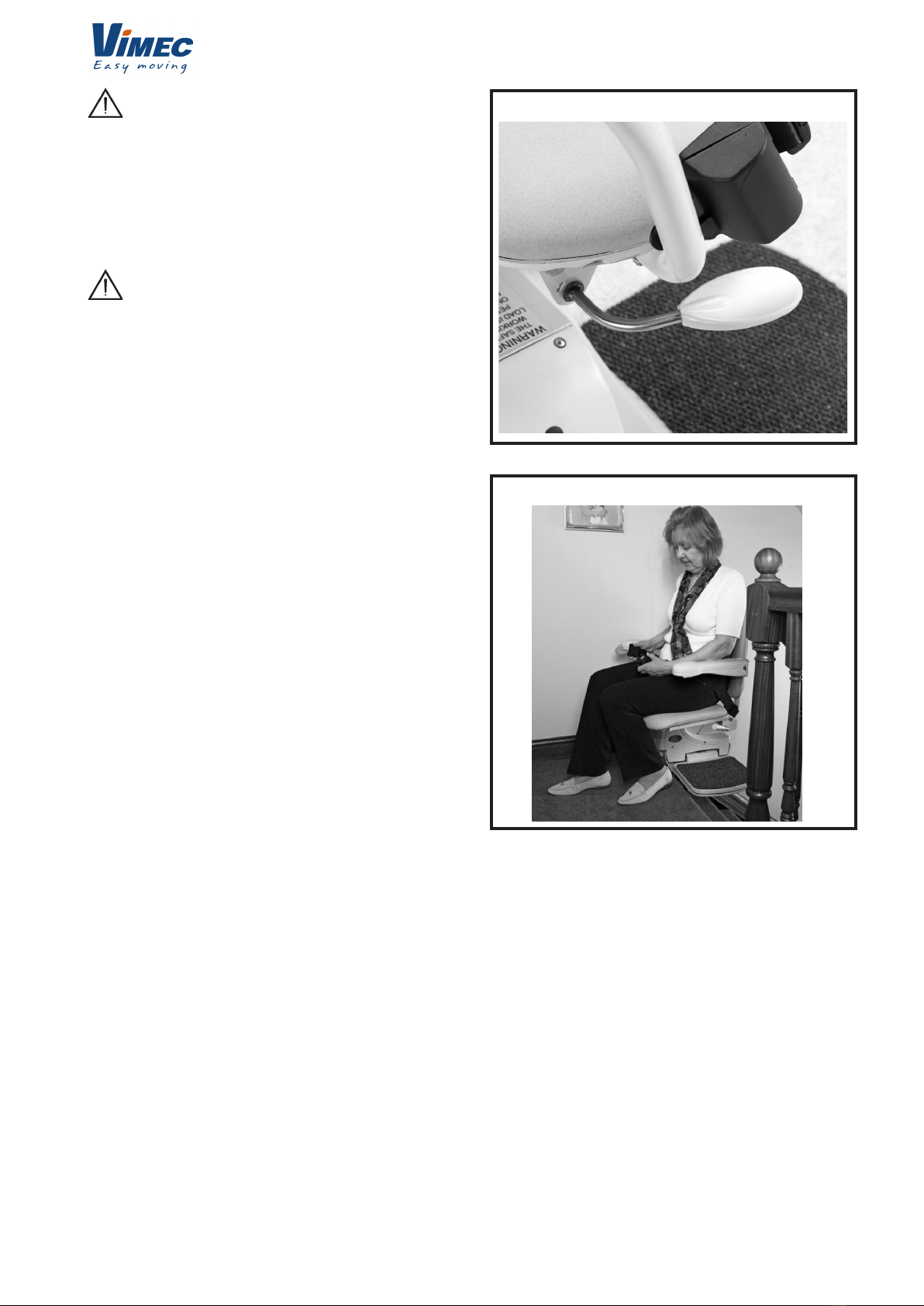

SAFETY PRECAUTIONS :

NEVER

Swivel the seat without the lap belt

fastened.

NEVER

Mount or dismount the swivel seat unless it is

locked in position.

NEVER

Try to operate the swivel seat whilst the

stairlift is in motion. (As a safety precaution,

should you try to use it whilst the lift is in motion,

it will cause the lift to stop).

ALWAYS

Use the swivel seat to travel up or down

the staircase in the correct position (i.e.

facing directly across the staircase).

2.8) Hinged track

Manual (optional)

In some installations a manual hinged track may be

necessary, usually to move the track out of the way of

the doorway at the foot of the stairs.

Before raising the manual hinged track, park the

stairlift near the hinged track or at the upper oor.

- Parking the Stairlift

WHEN THE STAIRLIFT IS NOT IN USE IT SHOULD

BE MOVED TO ITS PARK POSITION SO THAT IT

DOES NOT CAUSE AN OBSTRUCTION.

THE STAIRLIFT DOES NOT CHARGE WHEN IT

IS PARKED AT THE BOTTOM OF THE STAIRS (IN

CASE OF HINGED TRACK).

Your stairlift will not work unless the track has

been lowered.

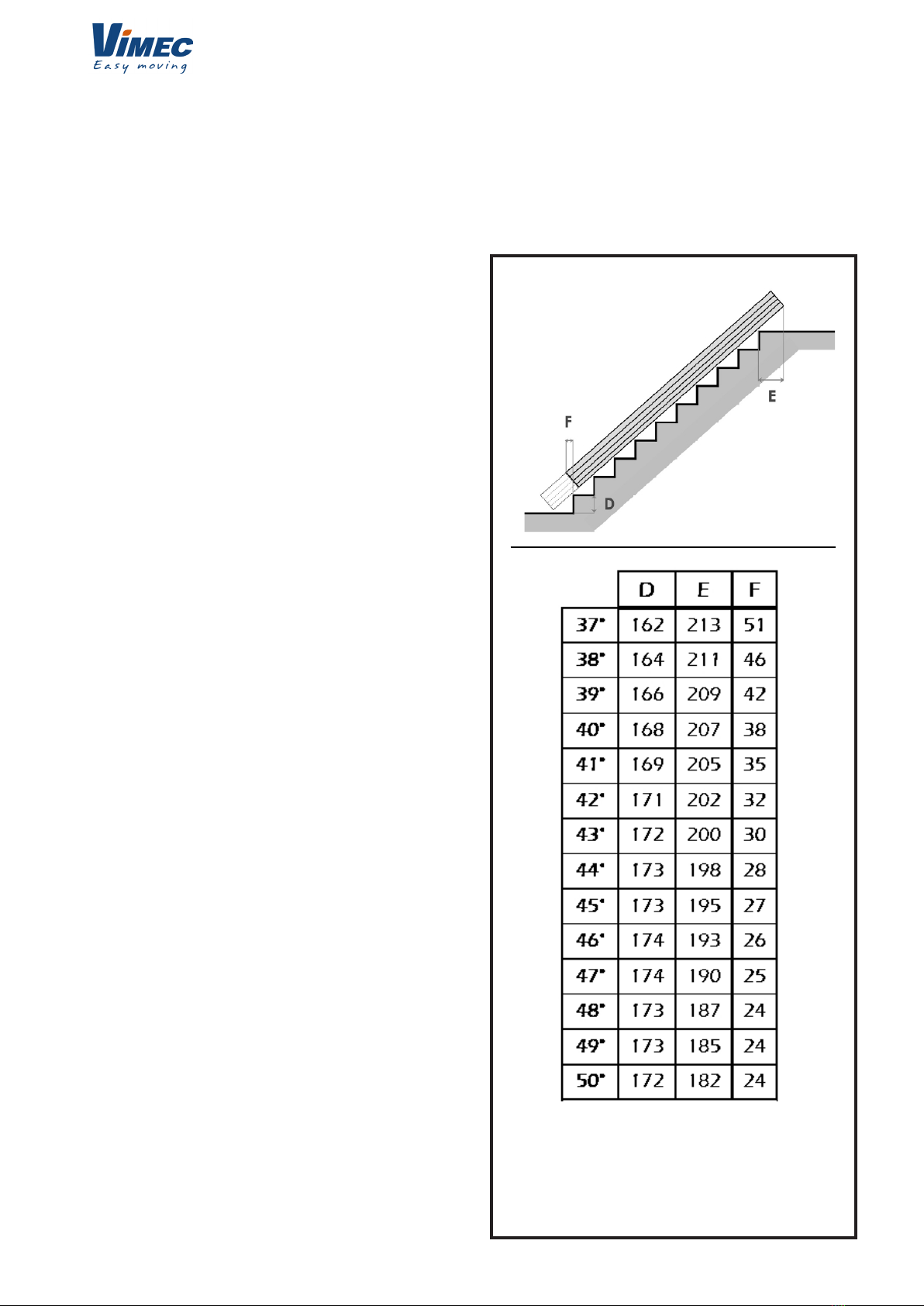

2.9) Motorised Slide Track

SlideTrack is a revolutionary addition to solutions

offered by the various types of stairlifts, eliminating the

need for installing hinged track on straight staircases.

• SlideTrack eliminates the potential danger of being

trapped, common to all hinges.

• SlideTrack’s minimum intrusion on either side of the

FIG.8

FIG.9

staircase reduces the risk of being trapped.

• Automatic operation makes SlideTrack easy to use.

• SlideTrack is the most suitable and accurate

alternative to hinged track.

• SlideTrack is easy to use, especially compared to a

standard hinge.

• Basically, SlideTrack guarantees safe use, it is easy

to install and use.

SlideTrack is shorter overall than track with a hinge.

When the lifter is in the parked position on the low part

of the staircase, SlideTrack does not reach the upper

landing.

When the track comes to its nal position on the upper

landing, it stops. The stairlift will continue along the

track until it reaches the end of the track.

Likewise, when it moves down the track it will continue

with the lifter until it reaches the ground oor where it

stops. The lifter will continue to move until it reaches

the end of the track.