7502040

7) CORRECT USE OF THE STAIRLIFT IN INDEPEN-

DENT ARM AND RETRACTABLE ARM VERSIONS

WARNING: READ THIS MANUAL CAREFULLY

BEFORE USING THE LIFT. The lift must only be

used in accordance with the intended uses descri-

bed in section 5.

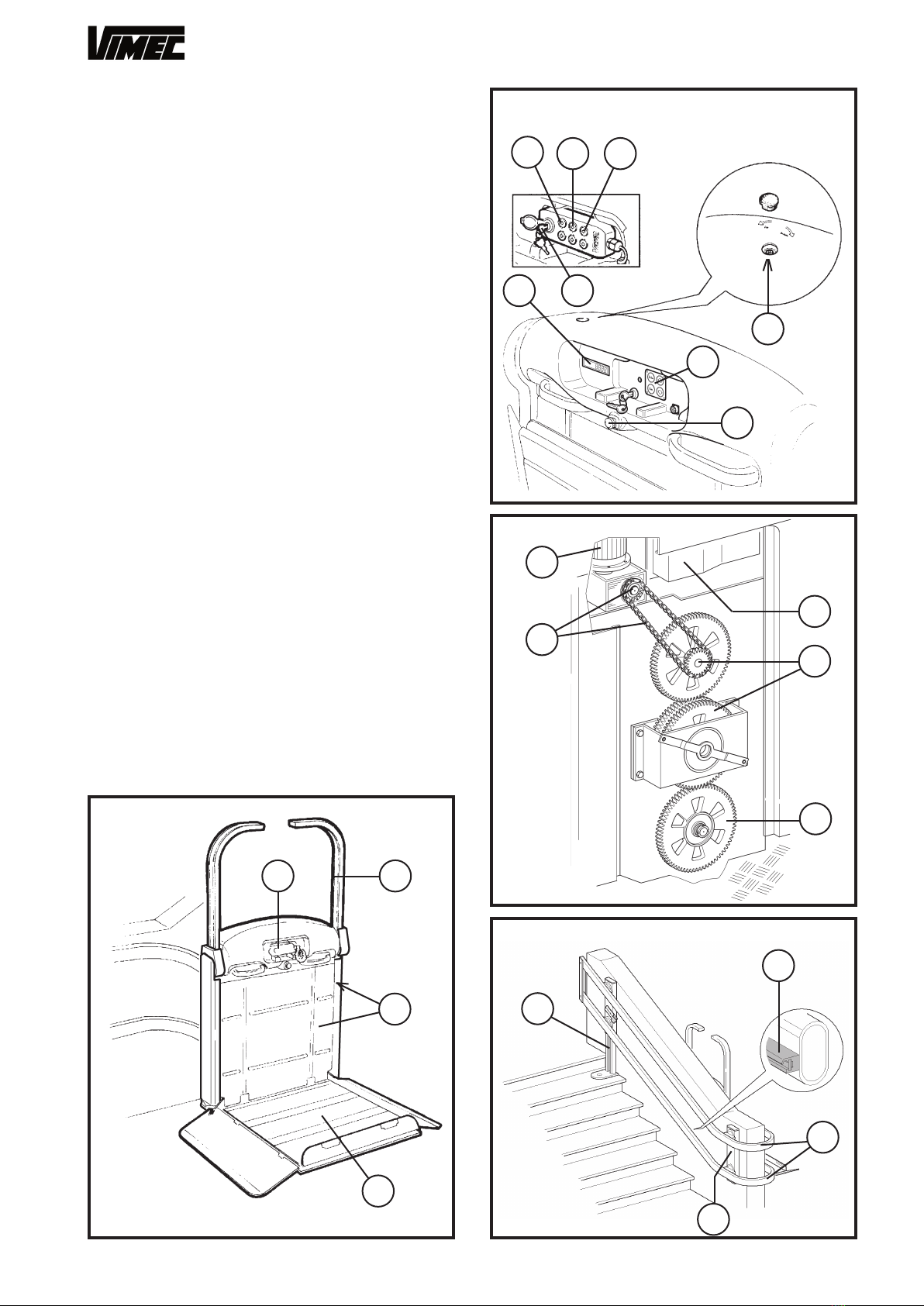

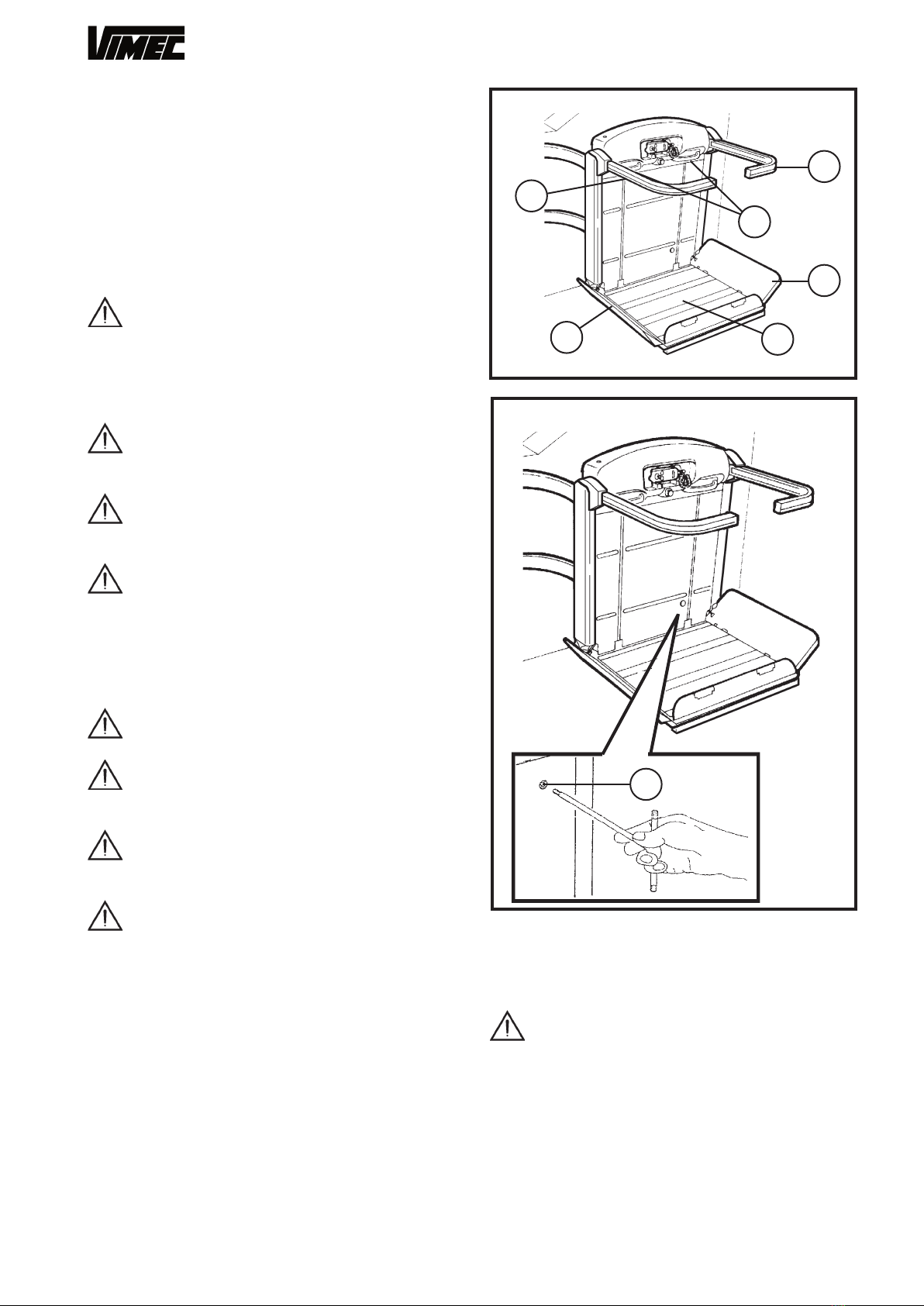

7.1) Starting position

Lift parked at one end of the staircase with the platform

raised (Fig. 8/a) and the arms in the rest position (Fig. 8/

b) with the master and power switches turned to ON.

7.2) Using the stairlift

WARNING: Always keep the access to the

platform and master switch unobstructed.

NEVER overload the lift.

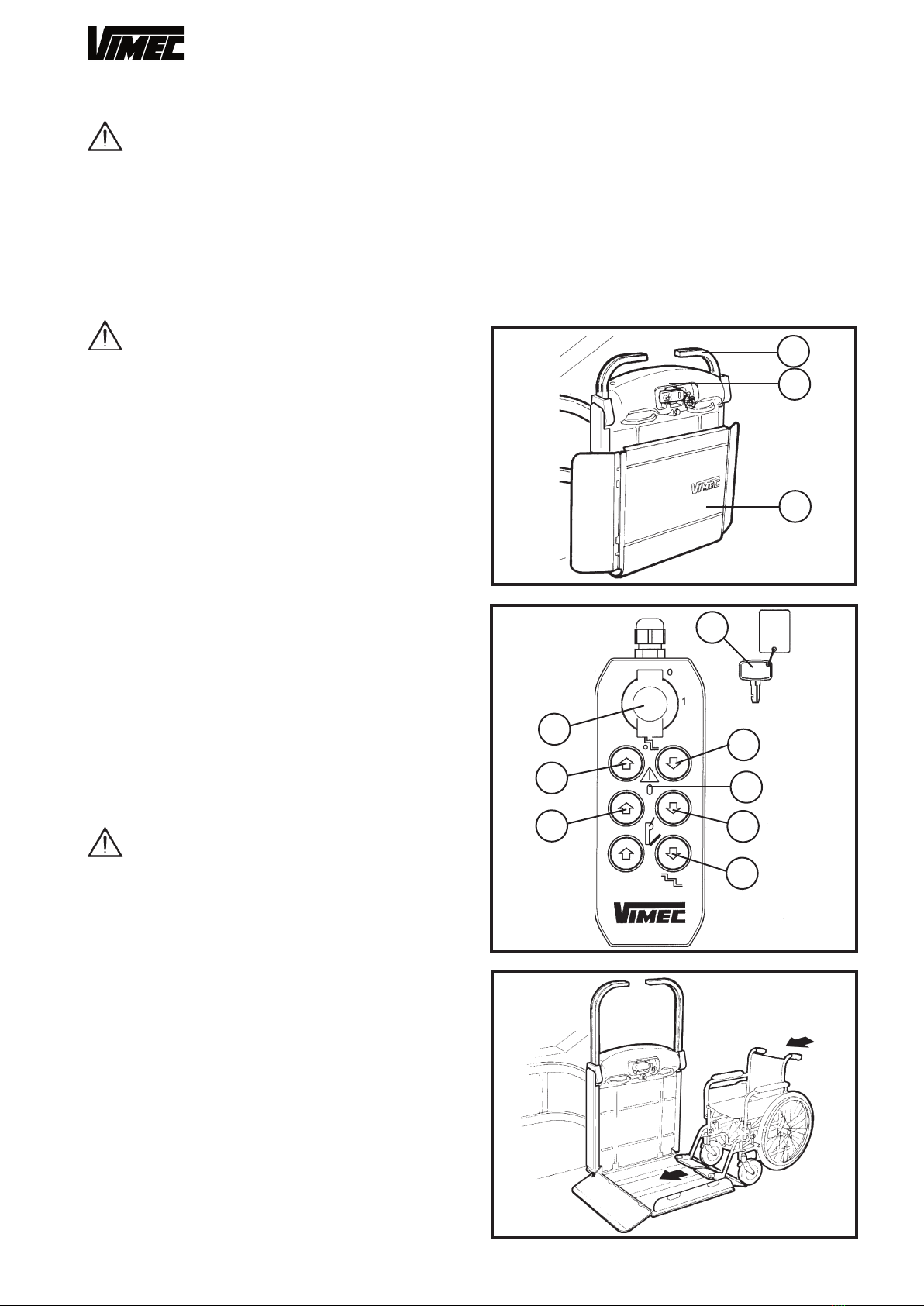

1) For lifts with manual platform (standard)

- Move the arm on the descent side into the working

position by pressing the button (Fig. 9/e) on the con-

trol panel on the lift or at the floor (optional).

- Lower the platform by hand.

- If the lift is at the bottom floor, return the descent side

arm to the rest position (Fig. 9/b) to allow the wheel-

chair to move onto the platform.

1) For lifts with motor-operated platform (optional)

- Insert the key (Fig.9/a) on the control panel on the lift or

at the floor (optional) and turn it to (1) ON. - Fig.9/g.

- Open the platform by pressing the button provided

(Fig. 9/e).

The flap sets in the embarkation position with the de-

scent side arm in the working position.

If the lift is at the bottom floor, return the descent side

arm to the rest position to allow the wheelchair to move

onto the platform.

2) Get onto the platform, facing in the travel direction

and positioning yourself centrally (Fig.10) to allow the

flap to provide its pressure-sensitive safety function.

Engage the wheelchair’s brakes; if it is electric, switch

it off.

WARNING: When positioning the wheelchair

on the platform, make sure that no part of the body

or wheelchair can project beyond its edge. When

the lift is motion remain seated and do not move

or rock.

3) Insert the key (Fig.9/a) on the control panel on the

lift (Fig. 9/g) and turn it to (1) ON.

4) Press the up button (Fig. 9/c); the flaps and arms

automatically locate in the safety position and the lift

starts.

N.B.: Press the button (Fig. 9/f) to select the floor

(e.g. press once to select the first intermediate floor,

press twice for the second).

In stairlifts with an intermediate stop, the green led on

the pushbutton panel (Fig. 9h) and the one on the ca-

sing in a central position (Fig. 8c), blink when the stop

is reached. Therefore, if the intermediate stop is not

preselected, and you wish to stop there, release the

button when you see the green light blinking.

5) The lift stops at the destination floor; keep the up

button pressed and the arm and flap on the up side

automatically move to the disembarkation position. The

flap and arm on the down side are now locked in the

safety position, ensuring safety during disembarkation

and when the next passenger embarks.

FIG.8

FIG.9

FIG.10

9

b

f

e

d

c

g

a

b

a

h

c