3) Type Approval Standards

The sounder carries an EC Type Examination Certificate and

IECEx Certificate of Conformity, and have been certified to

comply with the following standards:

EN60079-0:2012+A11:2013 / IEC60079-0:2011 (Ed 6):

Explosive Atmospheres - Equipment. General requirements

EN60079-1:2007 / IEC60079-1:2007 (Ed 6):

Explosive Atmospheres - Equipment protection by flameproof

enclosures "d"

EN 60079-31:2014 / IEC60079-31:2013 (Ed 2):

Explosive Atmospheres - Equipment dust ignition protection

by enclosure "t"

4) Installation Requirements

The sounder must only be installed by suitably qualified

personnel in accordance with the latest issues of the relevant

standards:

EN60079-14 / IEC60079-14: Explosive atmospheres -

Electrical installations design, selection and erection

EN60079-10-1 / IEC60079-10-1: Explosive atmospheres -

Classification of areas. Explosive gas atmospheres

EN60079-10-2 / IEC60079-10-2: Explosive atmospheres –

Classification of areas. Explosive dust atmospheres

The installation of the sounder must also be in accordance

with any local codes that may apply and should only be

carried out by a competent electrical engineer who has the

necessary training.

5) Special Conditions of Use

Repair of the flamepath / flameproof joints is not permitted.

The enclosure is non-conducting and may generate an

ignition-capable level of electrostatic charges under certain

extreme conditions (such as high-pressure steam). The user

should ensure that the equipment is not installed in a location

where it may be subjected to external conditions that might

cause a build-up of electrostatic charges on non-conducting

surfaces.

Additionally, cleaning of the equipment should be done only

with a damp cloth.

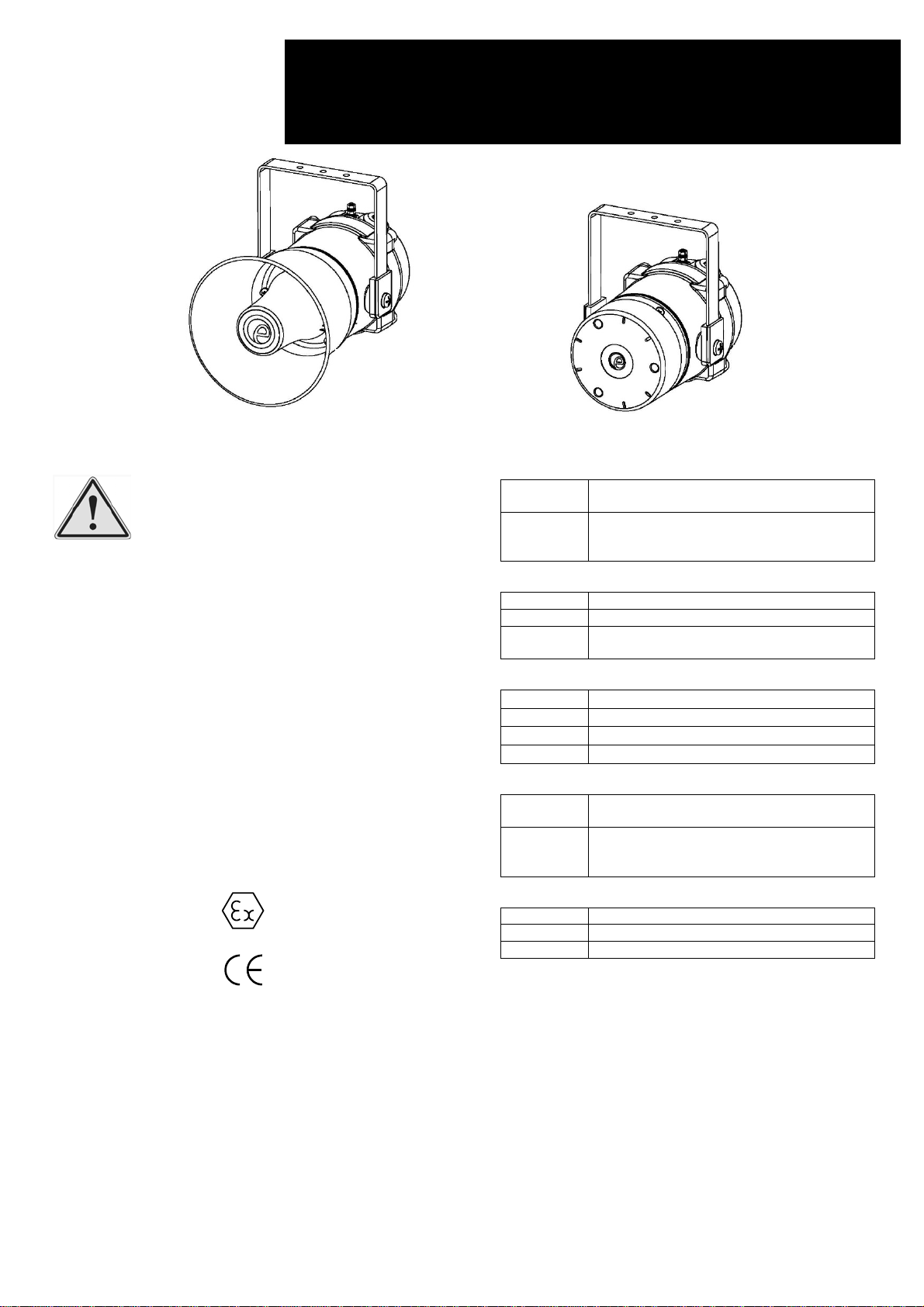

6) Location and Mounting

The location of the sounder should be made with due regard

to the area over which the warning signal must be visible.

They should only be fixed to services that can carry the

weight of the unit.

The BEx sounder should be secured to any flat surface using

the three 7mm fixing holes on the stainless steel U shaped

mounting bracket. See Figure 1. The required angle can be

achieved by loosening the two large bracket screws in the

side of the unit, which allow adjustment of the sounder in

steps of 18°. On completion of the installation then two large

bracket adjustment screws on the side of the unit must be

fully tightened to ensure that the unit cannot move in service.

Fig. 1 Fixing Location for Sounder Flare

Fig. 1 Fixing Location for Sounder Radial

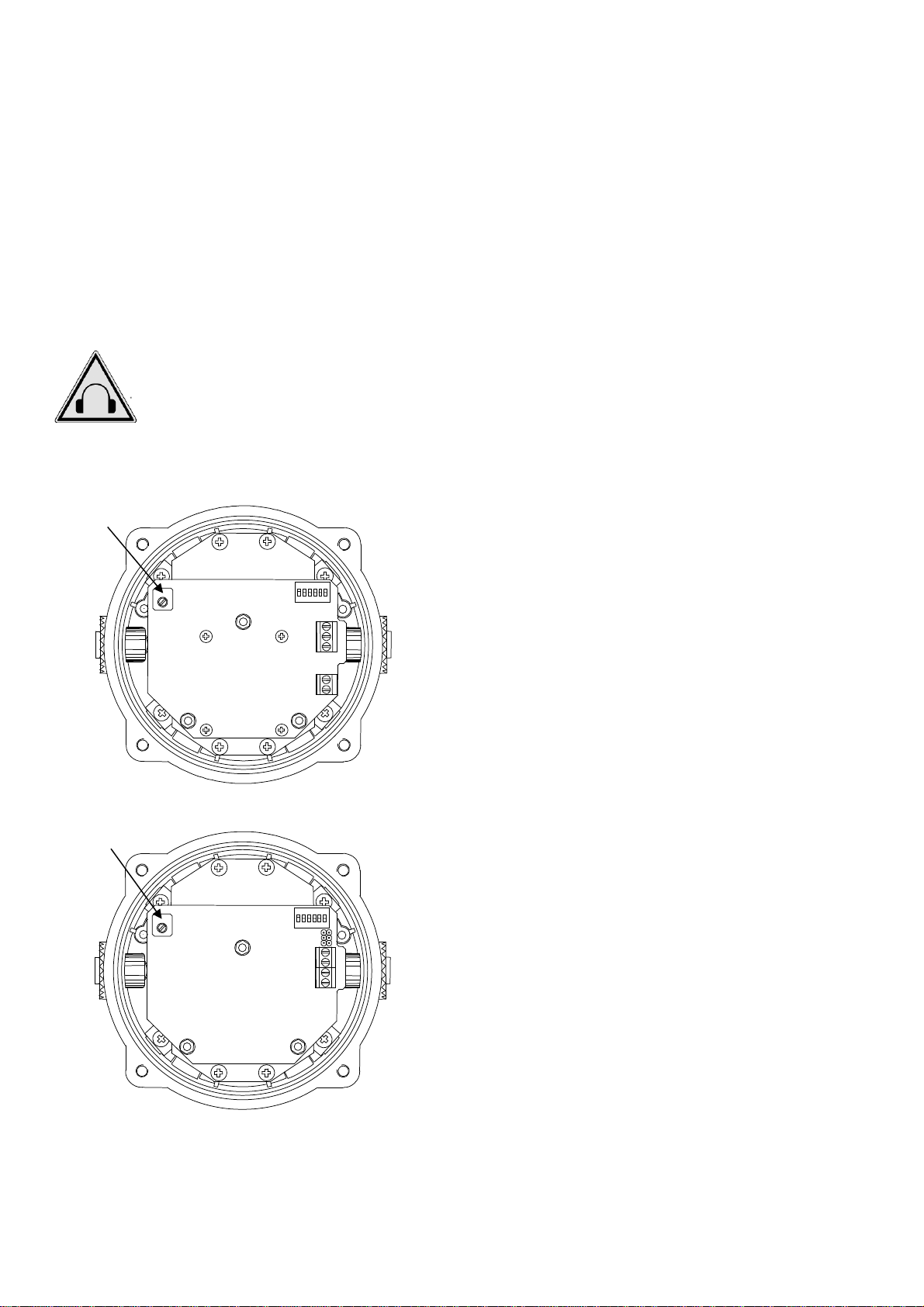

7) Access to the Flameproof Enclosure

To access the Ex d chamber, remove the four M6 hexagon

socket head screws and withdraw the flameproof cover taking

extreme care not to damage the flameproof joints in the

process. M6 cover screws are Class A4-80 stainless steel

and only screws of this category can be used for the

enclosure.

Fig. 2 Accessing the Explosion proof Enclosure.

On completion of the installation, the flameproof joints should

be inspected to ensure that they are clean and that they have

not been damaged during installation.

Check that the earth bonding wire between the two castings

is secure and the ‘O’ ring seal is in place. When replacing the

flameproof cover casting ensure that it is square with the

flameproof chamber casting before inserting. Carefully push

the cover in place allowing time for the air to be expelled.

Only after the cover is fully in place should the four M6

Stainless Steel A4-80 cover bolts and their spring washer be

inserted and tightened down. If the cover jams while it is

being inserted, carefully remove it and try again. Never use

the cover bolts to force the cover into position.

Warning – Hot surfaces. External surfaces

and internal components may be hot after

operation, take care when handling the

equipment.

Warning – High voltage may be present,

risk of electric shock. DO NOT open when

energised, disconnect power before

opening.

(Appropriate cable glands

to be customer su

lied

Flameproof cover

M6 Cover

Screws

M6 Spring

Washer

www.acornfiresecurity.com

www.acornfiresecurity.com