Manual VIPA TM-E Contents

HB39E - TME - RE_900-1E640 - Rev. 09/11 i

Contents

User considerations................................................................................. 1

Safety information....................................................................................2

Chapter 1 Assembly and installation guidelines............................1-1

Safety information for Users................................................................. 1-2

Installation dimensions ......................................................................... 1-3

Assembly.............................................................................................. 1-4

Cabling................................................................................................. 1-6

Installation guidelines ........................................................................... 1-7

Chapter 2 Hardware description .....................................................2-1

Properties............................................................................................. 2-2

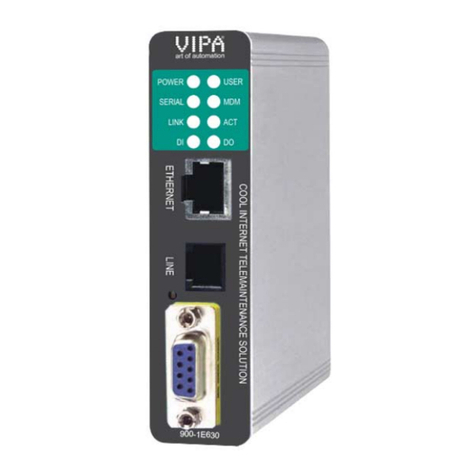

Structure .............................................................................................. 2-3

Technical Data ..................................................................................... 2-8

Chapter 3 Deployment .....................................................................3-1

Fast introduction................................................................................... 3-2

Assembly.............................................................................................. 3-5

Cabling................................................................................................. 3-6

TM-E - Configuration - eBuddy............................................................. 3-7

TM-E - Reset...................................................................................... 3-13

TM-E - Web page............................................................................... 3-14

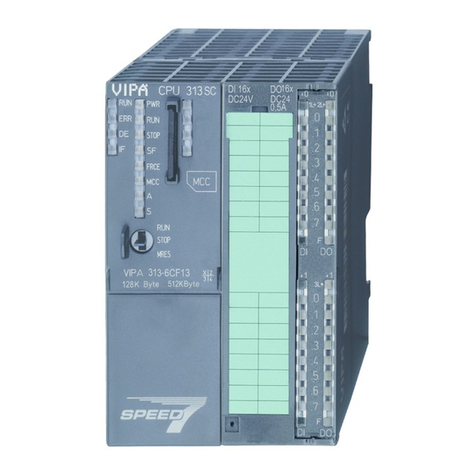

TM-E - PLC linking ............................................................................. 3-16

TM-E - Project integration - PG/PC interface...................................... 3-19

Deployment of Tags ........................................................................... 3-24

Teleservice via telephone with MPI gateway ...................................... 3-27

Teleservice via telephone - Ethernet gateway .................................... 3-30

Teleservice via Callback function ....................................................... 3-33

Sending SMS via mail gateway .......................................................... 3-37

Appendix................................................................................................A-1

Index ....................................................................................................A-1