INSTRUCTION FOR USE ENGLISH

1

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................... 2

GUIDE PURPOSE AND CONTENTS .................................................................................................................. 2

HOW TO KEEP THIS INSTRUCTION FOR USE ............................................................................................... 2

DECLARATION OF CONFORMITY ................................................................................................................... 2

ACCESSORIES AND MAINTENANCE .............................................................................................................. 2

CHANGE AND IMPROVEMENT ........................................................................................................................ 2

SCOPE OF APPLICATION ................................................................................................................................... 2

MACHINE IDENTIFICATION DATA ................................................................................................................. 2

TRANSPORT AND UNPACKING ....................................................................................................................... 3

SAFETY ........................................................................................................................................... 3

VISIBLE SYMBOLS ON THE MACHINE ........................................................................................................... 3

SYMBOLS THAT APPEAR ON THE INSTRUCTION FOR USE ...................................................................... 3

GENERAL SAFETY INSTRUCTION ................................................................................................................... 4

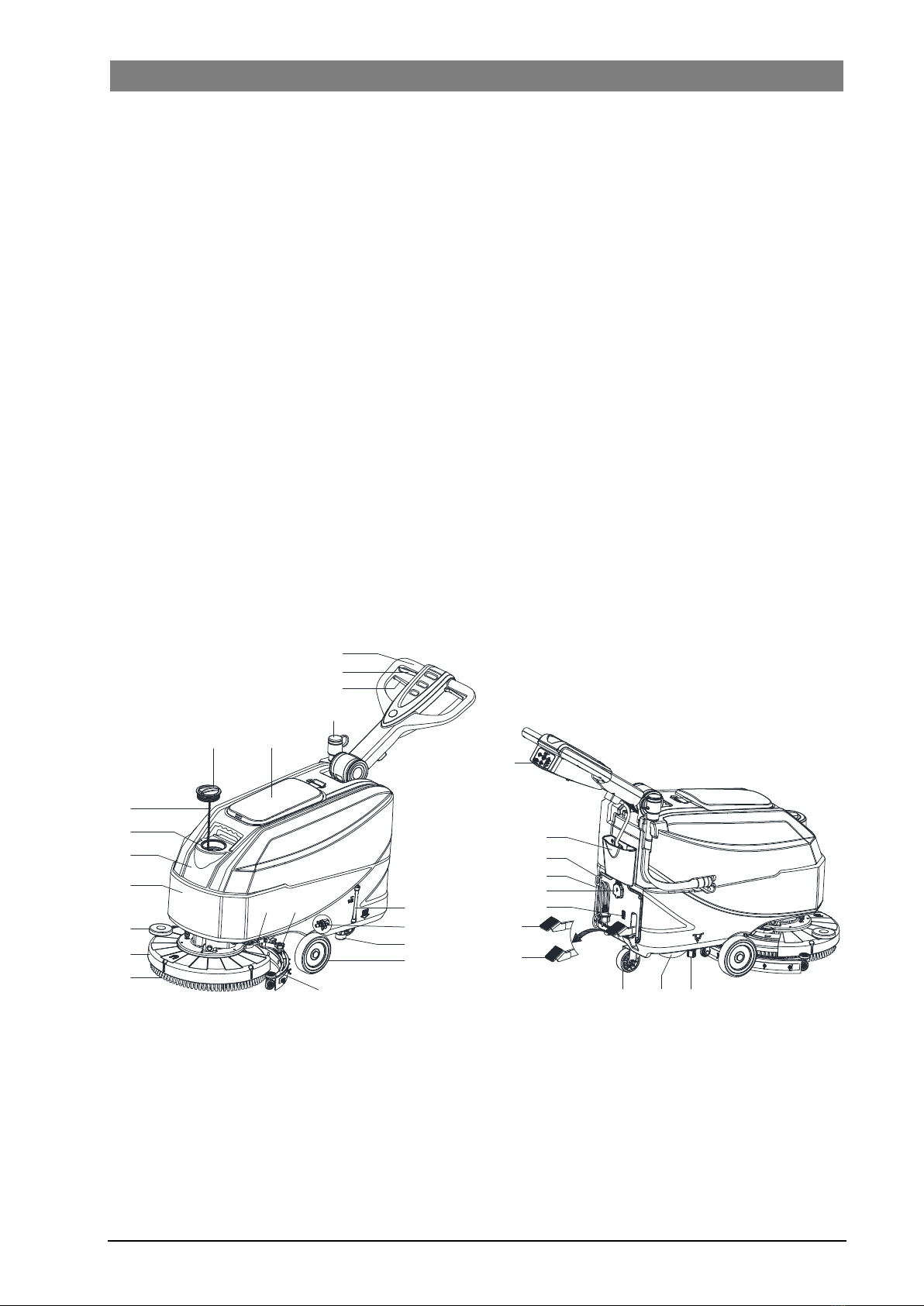

MACHINE DESCRIPTION .......................................................................................................... 6

MACHINE STRUCTURE ...................................................................................................................................... 6

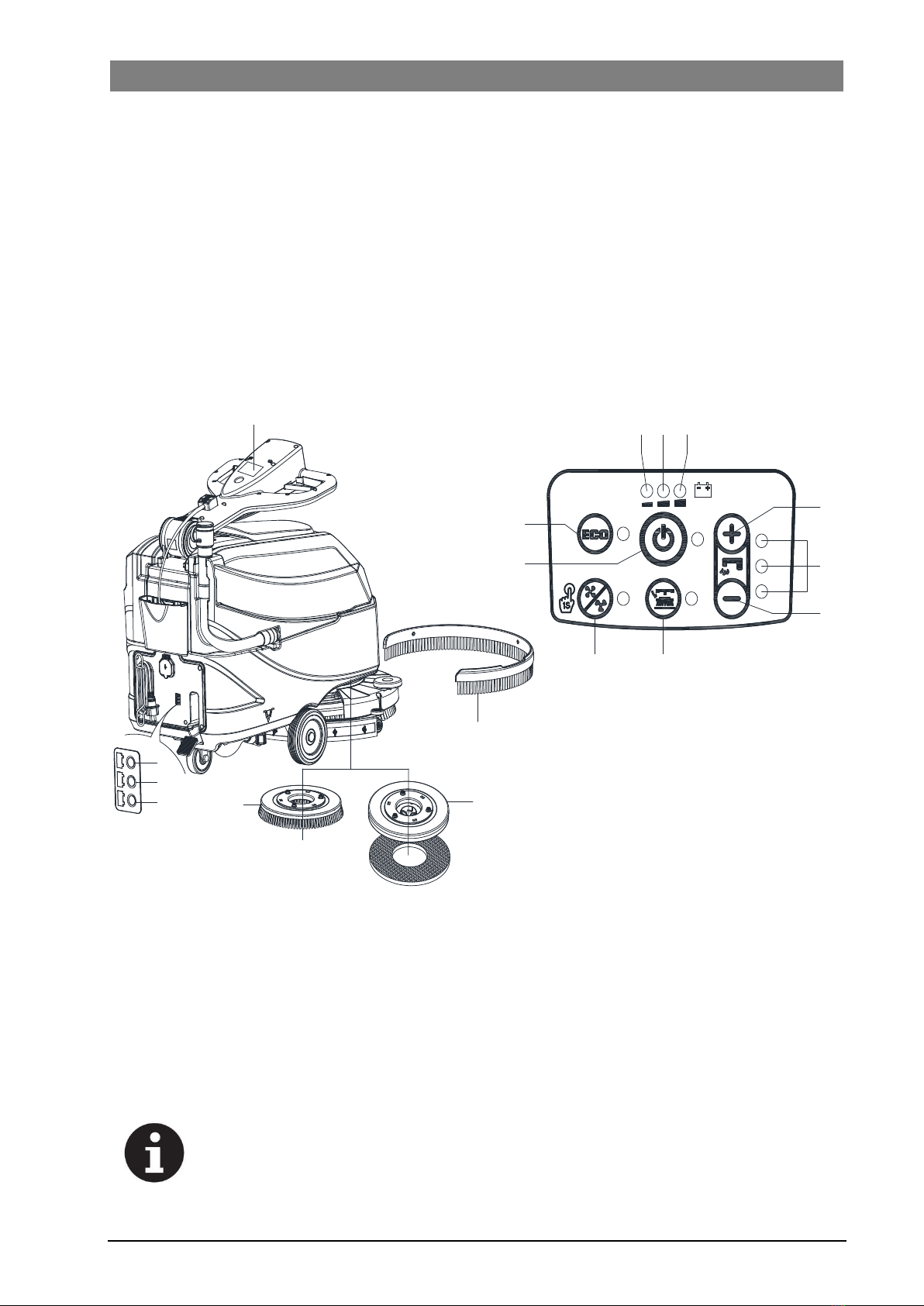

CONTROL PANEL ................................................................................................................................................ 7

DISPLAY WINDOW OF CHARGER INDICATON LIGHT ............................................................................... 7

MACHINE SIZE ..................................................................................................................................................... 8

TECHNICAL PARAMETERS ............................................................................................................................... 9

WIRING DIAGRAM ............................................................................................................................................ 10

OPERATING GUIDE................................................................................................................... 11

BATTERY CHECK/SETTING ON A NEW MACHINE .................................................................................... 11

BATTERY INSTALLATION AND BATTERY TYPE SETTING (WET OR GEL/ AGM) ............................. 12

BRUSH/PAD-HOLDER INSTALLATION AND REMOVAL ........................................................................... 14

SQUEEGEE ASSEMBLE INSTALLATION AND REMOVAL ........................................................................ 14

SOLUTION OR WASHING WATER TANK FILLING ..................................................................................... 15

MACHINE START AND STOP .......................................................................................................................... 16

MACHINE OPERATION (SCRUBBING AND DRYING) ................................................................................ 16

TANK EMPTYING .............................................................................................................................................. 17

AFTER USING THE MACHINE ......................................................................................................................... 18

MACHINE LONG INACTIVITY ........................................................................................................................ 18

FIRST PERIOD OF USE ...................................................................................................................................... 18

MAINTENANCE .......................................................................................................................... 18

SCHEDULED MAINTENANCE TABLE ........................................................................................................... 19

BATTERY CHARGING ...................................................................................................................................... 19

BRUSH/PAD CLEANING ................................................................................................................................... 21

SOLUTION FILTER CLEANING ....................................................................................................................... 21

SQUEEGEE CLEANING ..................................................................................................................................... 22

SQUEEGEE BLADE CHECK AND REPLACEMENT ...................................................................................... 23

TANK AND VACUUM GRID WITH FLOAT CLEANING, AND COVER GASKET CHECK ...................... 23

ACCESSORIES/OPTIONS .................................................................................................................................. 24

TROUBLESHOOTING................................................................................................................ 25

SCRAPPING .................................................................................................................................. 48