1 Introduction

1.1 General notes

Dear Customer,

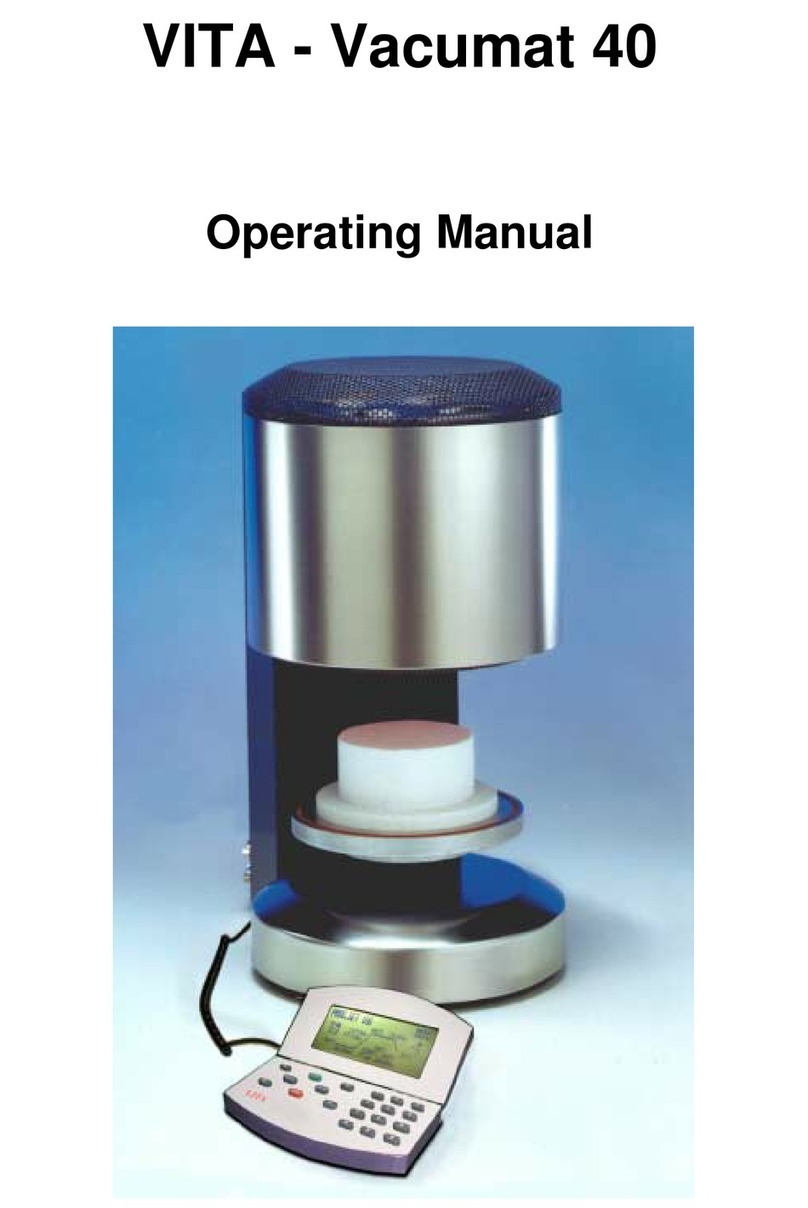

Congratulations on the purchase of your new VITA ZYRCOMAT 6000 MS. By choosing this sintering furnace, you have acquired a

future-oriented, modularly designed system of VITA's New Generation which you can add extensions to at any time in accordance

with your current and any future needs. The VITA family of New Generation furnaces gives you the flexibility and efficiency

needed to prosper in the working world of digitized dental technology.

Like all VITA furnaces, the VITA ZYRCOMAT 6000 MS also has a variety of technical features that help you achieve outstanding

results over the long term. For example, high-quality temperature control and adjustment ensure an accuracy of +/- 2°C across

the entire temperature range up to 1600°C. The Kanthal-brand, molybdenum disilicide heating elements used in VITA ZYRCOMAT

6000 MS are one guarantee that you will achieve consistent sintering results for many long years. All types of dental ceramic

framework materials based on zirconium dioxide or aluminum oxide can be processed.

Please read this operating manual carefully before use.

This operating manual is an important aid for operating the device successfully and safely.

The operating manual contains important information on how to use the device safely, appropriately and efficiently. Adherence to

the information contained in this manual helps to prevent risks, reduce repair costs and downtime and increase the reliability and

service life of the device.

All of the illustrations and drawings in this operating manual are intended for general explanatory purposes and are not

authoritative for the detailed construction of the device.

This operating manual must always be kept close to the device. It must be read and followed by all persons responsible for

working with/on the device, for example in relation to:

• Operation,

• Troubleshootingworkroutines

• Careandcleaning

• Servicing(maintenance,inspection,repairs).

1.2 Copyright

Important notes concerning copyrights:

© Copyright 2011, VITA Zahnfabrik. All rights reserved.

This document and/or the software, data and information referenced or contained herein contain confidential and proprietary

information of VITA Zahnfabrik.

This document does not convey or represent any right or license to use any software, data or information, any right or license

to use any intellectual property rights, or any obligation on the part of VITA Zahnfabrik to provide support or other services in

connection therewith. Any right or license to use any software data, information or other intellectual property rights of VITA

Zahnfabrik, or any obligation to provide services, must be conveyed by separate written agreement with VITA Zahnfabrik.