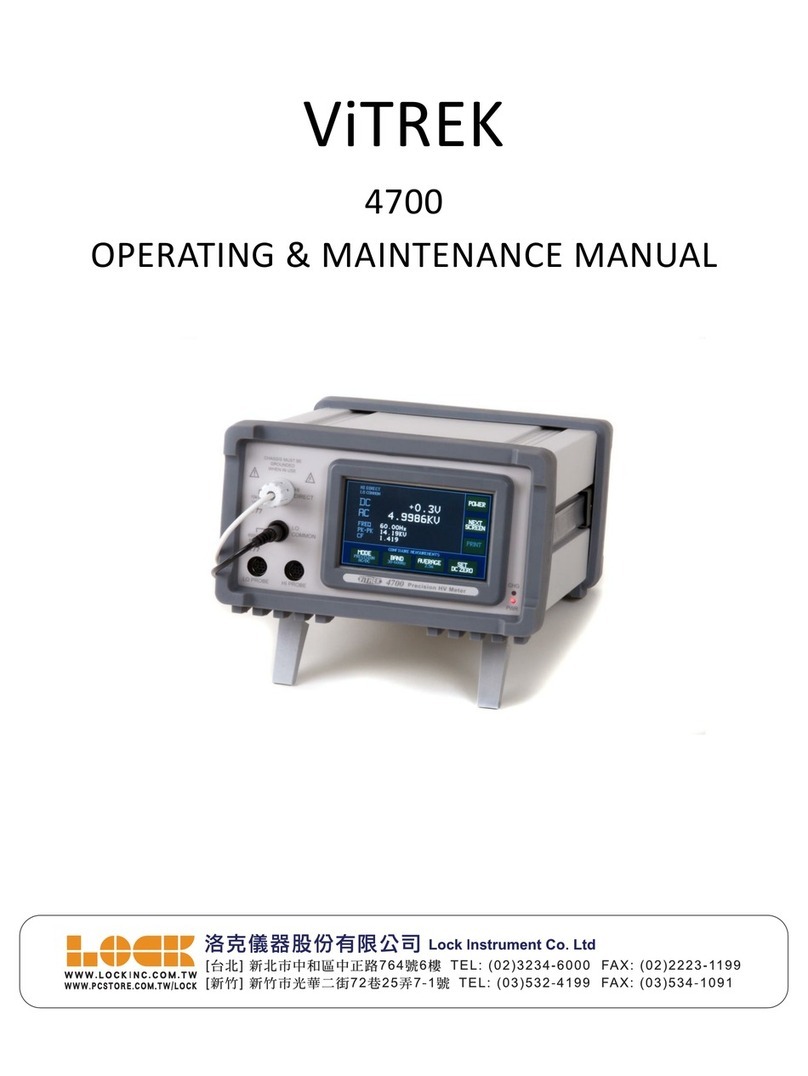

Vitrek Xitron 6000-2 User manual

USER’S GUIDE

6000-2 & 6000-3

Phase Angle Voltmeters

Warranty 3

Warranty

This Vitrek instrument is warranted against defects in material and workmanship for

a period of two years after the date of purchase. Vitrek agrees to repair or replace

any assembly or component (except batteries) found to be defective, under normal

use, during the warranty period. Vitrek'sobligation under this warranty is limited

solely to repairing any such instrument, which in Vitrek'ssole opinion proves to be

defective within the scope of the warranty, when returned to the factory or to an

authorized service center. Transportation to the factory or service center is to be

prepaid by the purchaser. Shipment should not be made without prior authorization

by Vitrek.

This warranty does not apply to any products repaired or altered by persons not

authorized by Vitrek or not in accordance with instructions provided by Vitrek. If

the instrument is defective as a result of misuse, improper repair, or abnormal

conditions or operations, repairs will be billed at cost.

Vitrek assumes no responsibility for its product being used in a hazardous or

dangerous manner, either alone or in conjunction with other equipment. Special

disclaimers apply to this instrument. Vitrek assumes no liability for secondary

charges or consequential damages, and, in any event, Vitrek'sliability for breach of

warranty under any contract or otherwise, shall not exceed the original purchase

price of the specific instrument shipped and against which a claim is made.

Any recommendations made by Vitrek or its representatives, for use of its products

are based upon tests believed to be reliable, but Vitrek makes no warranties of the

results to be obtained. This warranty is in lieu of all other warranties, expressed or

implied and no representative or person is authorized to represent or assume for

Vitrek any liability in connection with the sale of our products other than set forth

herein.

Instrument Serial Number: _________________________________________

46000-2 & -3 User Guide, Rev E

Document Part Number MO-6000-M Revision E

Copyright

Copyright© 1995–2005 Vitrek. All rights reserved.

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any form

with prior written consent from Vitrek. This product manual is copyrighted and

contains proprietary information, which is subject to change without notice. The

product displays and manual text may be used or copied only in accordance with the

terms of the license agreement.

is a trademark of Vitrek. All other trademarks or

registered trademarks are acknowledged as the exclusive property of their respective

owners.

In the interest of continued product development, Vitrek reserves the right to make

changes in this guide and the product it describes at any time, without notice or

obligation.

Vitrek

Manufacturers of Engineering & Production Test Equipment

12169 Kirkham Road

Poway, CA 92064

(858) 689-2755

E-Mail: [email protected]

Contents 5

Contents

Warranty_________________________________________________ 3

Introduction _____________________________________________ 11

Features _________________________________________________11

Principles of Operation _____________________________________12

Central Processor _______________________________________ 12

Signal Conditioning and DSP Sections ______________________ 13

Input Scaling___________________________________________ 14

Amplitude Measurement Circuitry and DSP __________________ 14

Frequency Measurement _________________________________ 15

Range/Mode Control ____________________________________ 15

Sample Clock Generation _____________________________ 15

Filter Clock Generation _______________________________ 16

Front Panel Operation _____________________________________ 17

Front Panel Operational Features______________________________17

Power Switch __________________________________________ 17

The Display ___________________________________________ 17

Display Select Keys _____________________________________ 18

The Up and Down Arrow Keys ____________________________ 19

The Left and Right Arrow Keys____________________________ 19

Total & Harms Keys_____________________________________ 19

Numeric Entry Keys_____________________________________ 20

Clear & Enter Keys _____________________________________ 20

Store & Recall Keys_____________________________________ 20

Setup Key_____________________________________________ 21

Local Key & Indicator ___________________________________ 21

Calibration Key ________________________________________ 22

Print Key______________________________________________ 22

The Nullmeter _________________________________________ 22

Input Connector Keys & Indicators _________________________ 23

66000-2 & -3 User Guide, Rev E

Making Input Connections___________________________________24

Guard Connections______________________________________ 24

Input Cables ___________________________________________ 25

Using the Operational Keys __________________________________25

Changing Displayed Information or Settings__________________ 25

Setting Defaults ________________________________________ 27

Entering New or Changed Information ______________________ 30

Setting/Formatting Time & Date ___________________________ 31

Storing & Retrieving Configurations___________________________32

Store & Recall Memory Menus ____________________________ 33

Storage Area Maintenance ________________________________ 34

Repacking of the Storage Areas____________________________ 35

Rear Panel ______________________________________________ 37

Connectors & Controls _____________________________________37

Power Connection ______________________________________ 38

Configuration Control Switch _____________________________ 38

Parallel Printer Interface__________________________________ 38

RS232 Connectors ______________________________________ 38

IEEE488 Connector _____________________________________ 38

Configuration Setup_______________________________________ 39

Setup Guidelines __________________________________________39

Input Configuration Menu ___________________________________43

Input Scaling___________________________________________ 43

Guard ________________________________________________ 43

Measurement Configuration Menu ____________________________44

Fundamental Frequency__________________________________ 44

Fundamental Frequency Range ____________________________ 45

Fundamental Source_____________________________________ 45

Nominal Amplitude Measurement Period ____________________ 46

Filter Frequency ________________________________________ 47

Maximum Harmonics____________________________________ 47

Fundamental÷Bandwidth _________________________________ 48

Analysis ______________________________________________ 48

Fundamental Frequency Averaging _________________________ 49

Fundamental Frequency Measurement Period_________________ 49

Nullmeter Display Menu ____________________________________49

Nullmeter Parameter Types _______________________________ 49

Contents 7

Parameter Display Menus ___________________________________50

Parameter (p) __________________________________________ 50

Reference Parameter (r) __________________________________ 54

Reference Parameter Type ________________________________ 54

Data Result Units _______________________________________ 54

Comparison Limit_______________________________________ 55

Filter Time Constant_____________________________________ 56

Some Useful Hints ______________________________________ 56

Showing Percentages & dB Changes_____________________ 56

Unstable Displayed Results ____________________________ 57

Display Line Format _______________________________________57

Nullmeter Scale Menu ______________________________________58

Scale Factor ___________________________________________ 58

Type _________________________________________________ 59

Additional Application Examples _____________________________60

Interface Operation _______________________________________ 63

RS232 Data Format Selection ________________________________63

IEEE488 Interface Setup ____________________________________64

Configuring the Controller Card ___________________________ 65

Configuring the Controller Software ________________________ 66

Interrogating the Data ______________________________________67

Reading Data __________________________________________ 67

Sending Data __________________________________________ 68

RS232 Interfacing_______________________________________ 69

IEEE488 Interfacing_____________________________________ 69

Bus Timing_________________________________________ 69

Bus Commands _____________________________________ 69

Application for the Lower Case Portions of Commands______ 70

Command Set_____________________________________________71

Interface Commands_____________________________________ 71

Available Parameter Strings_______________________________ 74

Retrieving Parameters ________________________________ 75

Source and Bandwidth Strings__________________________ 79

Sub-Definition Strings ________________________________ 80

Special Parameter Strings _____________________________ 81

ID Data Format _____________________________________ 82

UNITS=String Format ________________________________ 82

Full-Parameter Definition Format _______________________ 84

86000-2 & -3 User Guide, Rev E

High Speed Operation ______________________________________85

Measurement Periods____________________________________ 85

Frequency Measurement _________________________________ 85

Harmonic Measurement__________________________________ 85

Interrogating Results ____________________________________ 85

Maintenance & Calibration _________________________________ 87

Daily Maintenance_________________________________________87

Low Level DC Measurements _____________________________ 87

Procedure without Equipment __________________________ 87

Procedure with Equipment_____________________________ 88

External Calibration________________________________________89

Preparation for Calibration________________________________ 90

Required Equipment_____________________________________ 91

Calibration Procedure____________________________________ 91

Performing a Partial Calibration ______________________________93

Performing a Calibration Check Only __________________________93

Appendix A: AIO Option___________________________________ 95

AIO Option Features _______________________________________95

AIO Option Commands_____________________________________95

Appendix B: Specifications _________________________________ 97

Voltage Input _____________________________________________97

Current Input _____________________________________________98

Input Filtering ____________________________________________98

Phase ___________________________________________________98

Fundamental Frequency Measurement _________________________99

Harmonic Analysis_________________________________________99

Peak Parameters__________________________________________100

Date and Time ___________________________________________100

General_________________________________________________100

Contents 9

Figures

Figure 1. System Block Diagram _______________________________________12

Figure 2. Digital Signal Processing Block Diagram_________________________13

Figure 3. Sample Clock_______________________________________________16

Figure 4. The 6000-3 Voltmeter Front Panel ______________________________17

Figure 5. Display Showing Results Data _________________________________18

Figure 6. The Nullmeter ______________________________________________22

Figure 7. Input Terminals _____________________________________________23

Figure 8. Display Line Configuration Data_______________________________26

Figure 9. Rear Panel Partial View_______________________________________37

Figure 10. Initial Setup Display ________________________________________39

Figure 11. Setup Measurements Display__________________________________40

Figure 12. Input Configure Display _____________________________________41

Figure 13. Nullmeter Sample Display____________________________________42

Configuration Examples

ØTo change a display line of Results Data: _______________________________26

ØTo select an option: ________________________________________________26

ØTo set defaults:____________________________________________________27

ØTo abort a displayed menu and discard any changes: ______________________28

ØTo change a display line: ____________________________________________28

ØTo adjust a “noisy” measurement (to a given value): ______________________29

ØTo provide a “fast/medium/slow” style of adjustment capability: ____________29

ØTo add display lines (up to 50 lines possible): ___________________________30

ØTo delete a display line:_____________________________________________30

ØTo add dashes in a display line as a separator: ___________________________30

ØTo “enter” data and changes into the menu—when the cursor is flashing:______30

ØTo “enter” data and changes into the menu—when no cursor is visible: _______31

ØTo adjust the time display:___________________________________________31

ØTo format the time display: __________________________________________32

ØTo set the date format: ______________________________________________32

ØTo set the date display: _____________________________________________32

10 6000-2 & -3 User Guide, Rev E

ØTo store a configuration in an already defined storage area:_________________33

ØTo store a new configuration (presently displaying): ______________________33

ØTo recall a configuration:____________________________________________34

ØTo rename an existing storage area:____________________________________34

ØTo delete a storage area: ____________________________________________34

ØTo manually prompt the repacking of storage areas:_______________________35

ØSetting fundamental frequency mode and range for input connectors: _________39

ØSetting the input mode for each input connector: _________________________41

ØTo change the (input) scale factor: ____________________________________42

ØSetting the Guard connection for each input connector: ____________________42

ØTo configure the Nullmeter parameter display:___________________________42

ØTo complete a configuration setup: ____________________________________43

ØTo measure signal content of harmonics, amplitude, phase, and sync:_________60

ØTo measure harmonic content, or wideband amplitudes synchronously: _______61

ØTo perform spectral analysis of the input signal.__________________________62

ØTo measure wideband amplitudes over a known period of time: _____________62

ØTo perform an external calibration:____________________________________91

ØTo perform a calibration check:_______________________________________93

Introduction 11

Introduction

Congratulations on purchasing one of the high technology signal analysis

instruments available from Vitrek. The 6000 family of Phase Angle Voltmeters

offers the utmost in accuracy and flexibility.

These instruments contain an automatic switching power supply, thus no changes are

required for local AC supply voltage or frequency variations, simply select the power

cord extension that connects to your supplied power.

Features

The Phase Angle Voltmeter instruments are available as a two input, the 6000-2, and

as a three input, the 6000-3. Both have full accuracies available on all inputs fitted.

The following lists some of their significant features.

•Fully digital signal processor (DSP) based operation, no analog phase-locked

loops, phase detectors or other delicate, inaccurate circuitry. These instruments

have a 0.0005Hz to 200kHz range of frequencies.

•True 18-bit resolution on each input, which yields exceptional phase, amplitude

and harmonic resolution.

•500kHz sampling frequency on each input simultaneously, which yields

excellent high frequency accuracies, even with heavily distorted waveforms, and

the widest range of harmonics measurement (up to the 2047th harmonic).

•DSP based fundamental frequency component detection, which yields the widest

range of fundamental “reference” input, even when buried in noise and

distortion.

•Two 40mHz 24-bit Digital Signal Processors for each pair of inputs, and one

68020 32-bit Central Processor, which yields the highest measurement speeds

available.

•Full Range of measurement capabilities, not just amplitude, frequency and

phase. THD, inter-harmonic phase, spectrum analysis, cross-correlation are just

a few of the additional measurements available at the touch of a button.

12 6000-2 & -3 User Guide, Rev E

•Fully customizable display window. Shows 4 lines at a time and is scrollable to

50 lines.

•High resolution bargraph contains 101 elements and two supporting interface

keys.

•Both voltage and current input capabilities on each input, which allows for high

accuracy power measurements from a few nanowatts to hundreds of watts.

•The interface package adds control capabilites with the IEEE488 and RS232

connections; printing capacity with the Parallel printer connectors; and analog

output ability with 12 analog connections, when AIO option is fitted.

Principles of Operation

For basic details regarding the circuitry and methods used in the 6000 instruments,

Figure 1 shows the overall block description of their internal system’s circuitry.

Central Processor

The central processor consists of circuitry surrounding a Motorola 32-bit

MC68EC020 processor and a MC68882 math co-processor, both of which run at

25mHz. These processors perform all interfacing and inter-digital signal processing

and coordination required in the instrument.

Equation

Coprocessor

(MC68882)

Central

Processor

(MC68020)

Signal

Conditioning

and DSPs

(2xDSP56001)

Signal

Conditioning

and DSPs

(2xDSP56001)

Parallel Printer

2 x RS232

IEEE488

Front Panel

Interfaces

Flash

Memory

(up to 4 Mbyte)

A

B

Sync

Option AIO

Figure 1. System Block Diagram

Introduction 13

High Speed

56-bit

Digital

Signal

Processor

(DSP56001)

500KHz

18-bit

Digitizer

High Speed

Digital

LPfilter

(Variable)

500KHz

18-bit

Digitizer

High Speed

Digital

LPfilter

(Variable)

2MHz

8-bit

Digitizer

Analog

LPfilter

(1 MHz)

2MHz

8-bit

Digitizer

Analog

LPfilter

(1 MHz)

Digital

Noisy

Sample

Generator

Optical Isolation Barrier

Digital Peak

Detector

Digital HI-Q

BP Filter

Digital HI-Q

BP Filter

Digital Peak

Detector

Range/Mode

control

SYNCHRONOUS SAMPLE CONTROL

V

A

High Speed

56-bit

Digital

Signal

Processor

(DSP56001)

FREQUENCY MEASUREMENT

RANGE/MODE CONTROL

AMPLITUDE

MEASUREMENT

Range & Mode

The software run by this processor is stored in flash memory, allowing the

instrument’s software to be field upgradeable without requiring removal of the

covers or any circuitry. The interface of this processor to the interface components:

IEEE488, (2) RS232 and Parallel Printer is via the processor’s native bus interface.

This bus interface uses standard commercial integrated circuits for hardware. All of

these interfaces use interrupt driven software to perform their input/output duties,

yielding a high-speed interface.

Signal Conditioning and DSP Sections

For each pair of the instrument’s inputs, there is a set of circuitry that contains two

Motorola DSP56001 24-bit processors interfaced to the central processor. The

interface is made via a high speed RS485 data link. Refer to Figures 1 and 2.

Figure 2. Digital Signal Processing Block Diagram

14 6000-2 & -3 User Guide, Rev E

These sections also provide the primary isolation between the grounded digital

circuitry of the instrument and the floating input circuitry via an optical isolation

barrier, which passes digital signals only.

Each of these sections is capable of operating independently, or can be “joined” to

one or both of the other sections to perform simultaneous sampling, as required, by

the central processor.

Input Scaling

Each input has identical systems that perform the required scaling of the input

signals to the levels required by the amplitude and supervisory systems. Each

input’s scaling is fully differential throughout, and is powered by isolated power

supplies having its common driven by the respective GUARD terminal. In this

manner, excellent common-mode performance is achieved, and the signal quality

delivered to the respective amplitude and supervisory sections is maintained, even in

a digital “backplane” environment. Each input’s scaling and mode is controlled by

parallel digital codes provided by the relevant supervisory DSP. The form of

amplification chosen maintains excellent phase shift, even at high frequencies, using

many gain stages for amplification. Each gain stage is configured to produce the

same nominal phase shift independent of gain setting. Each input system also

presents the GUARD terminal connection to its amplitude and supervisory DSPs to

act as the common for their isolated power supply requirements.

Amplitude Measurement Circuitry and DSP

Each input, after scaling, is filtered by a high speed digital low-pass filter having its

corner frequency (filter clock frequency) controlled by one of three filter clocks

common to all amplitude systems. After filtering, each input signal is then converted

to 18-bit digital form by an 18-bit. analog-to-digital converter system, whose sample

clock is taken from one of three sample clocks common to all amplitude systems.

Each converter consists of a pair of time interleaved 250kHz converters, allowing for

sampling up to 500kHz. Refer to Figure 2, the Digital Signaling Processing Block

diagram.

The output of all four converters (two per input) is read by Motorola’s digital

converter, DSP56001, at a rate controlled by the same sample clock used by the

converters.

This processor performs all amplitude and harmonic analysis required by the system,

and maintains a database of the results of the latest such measurements for its

channel. The central processor gains access to these results via a high speed RS485

data link. This same link is used to pass to the DSP the selections to use for its

sample and filter clock signals, and details regarding the measurements to be made.

Introduction 15

The channel’s circuit board with this harmonic analysis DSP is internally named the

"Amplitude DSP".

Frequency Measurement

Each scaled input passes to a second sub-system for additional analysis. This second

sub-system is internally named the “Supervisor DSP” board and consists of the

following portions:

Filter and High Speed ADC—Each input passes through an analog 1mHz low

pass filter, and sampled at 2mHz by a pair of 8-bit analog-to-digital converters.

Supervisory Processor—The outputs of the pair of 8-bit converters is read by a

Motorola DSP56001, which performs several asynchronous tasks using this data.

This processor is linked to the central processor using the high speed RS485 data

link.

Range/Mode Control

Overload and Underload Detection—Each sample is checked for overload

status. If an overload is detected then the DSP changes the range presented to the

input scaling circuitry (if able) and informs the central processor that a range change

has occurred.

If an underload condition remains for longer than a period provided by the central

processor (actually set by the minimum fundamental frequency expected) then the

DSP changes the range presented to the input scaling circuitry (if able), and informs

the central processor that a range change has occurred. This process is continuous,

independent between the inputs, and completely independent of any other activities

in progress in the instrument. You can also set a fixed range, rather than the above

autorange process.

Bandpass Filtering and Frequency Measurement—Input samples are

passed through a proprietary system. The system performs a tracking bandpass filter

function, maintaining track of the fundamental frequency reading within set range.

This tracked frequency reading is then used to measure the frequency of the

remaining signal component. This process is continuous and independent between

the inputs, and completely independent of any other instrument or supervisory

processor activities in progress.

Sample Clock Generation

Under the direction of the central processor, the supervisory DSP controls circuitry

contained in an ASIC, which generates a digital clock signal whose average

16 6000-2 & -3 User Guide, Rev E

frequency is settable with 20-bit resolution over a 2:1 range of frequencies. This

clock signal is available to all amplitude DSP systems on one of three such signal

lines. If desired by the central processor, the supervisory processor can “link” this

frequency to that of either of its measured input frequencies. The form of the sample

clock is such that the individual sample-to-sample clock period can vary by up to

1%, however, the average over any 256 sample period is always within 1ppm of the

set value. This “jittered” sampling ensures that no input signal component can be

synchronous to the amplitude system’s sample rate, removing the anomalous effects

that occur when this happens.

Figure 3. Sample Clock

Filter Clock Generation

Under the direction of the central processor, the supervisory DSP controls circuitry

contained in an ASIC which generates a digital clock signal whose frequency is

selectable in 1.2:1 steps over 4.5 decades of frequencies. This clock signal is

available to all amplitude DSP systems on one of three such signal lines.

Front Panel Operation 17

Front Panel Operation

This section includes a description of the front panel interface features of the Phase

Angle Voltmeter instruments and their basic operation. Refer to Configuration

Control for an explanation of the menus.

Front Panel Operational Features

The 6000-2 and -3 Phase Angle Voltmeter instruments have a number of controls

and indicators available. See Figure 4.

Figure 4. The 6000-3 Voltmeter Front Panel

Power Switch

Turns the unit ON and OFF.

The Display

The front panel display is a “window” that provides a visual interface to the alpha-

numeric measurement Results Data and the changeable configuration menu. Refer to

Not installed on the 6000-2

18 6000-2 & -3 User Guide, Rev E

Figure 5. The instrument’s display can show (up to) four lines of information at one

time and maintains up to fifty lines of displayable measurement results, which are

accessible by scrolling. You can add or delete lines, as necessary. The display is the

interface focus, as it responds to all front panel key presses, showing the options

available for that key.

rms 118.7 Vrms B

rms 3.410 Arms B

true 350.2 W A

true 404.8 VA A

Figure 5. Display Showing Results Data

The display responds to all front panel keys described below. To place a cursor in a

display line, use a DISPLAY SELECT key, which are the corresponding unmarked keys

on the right. Press the ENTER key once to remove the cursor. Press it twice to action

the configuration.

Display Select Keys

The unmarked keys located to the right of the

display are called the DISPLAY SELECT keys.

The topmost key is 1, second is 2, third is 3, and

forth is 4:

•Use to bring up the configuration for each

line of Results Data, including blank lines.

•Use to place the cursor in the menu display.

•Use to page through the various parameter

screens using the topmost key identified

here as the DISPLAY SELECT 1 key; and

•Use in combination with arrow keys, to

scroll through options to edit a

configuration menu item.

1

2

3

4

Front Panel Operation 19

The Up and Down Arrow Keys

The éand êkeys (up and down arrows) are

part of the DATA ENTRY keypad. Use these keys:

•For scrolling the display Results Data lines,

one line at a time;

•To scroll through selectable options at a

cursor position;

•When no cursor displays, use the éand ê

keys to scroll through various parameter

menu details given in the last three

configuration menu lines.

The Left and Right Arrow Keys

The çand èkeys (left and right arrows) are

part of the DATA ENTRY keypad.

Use these keys:

•To move the cursor to a new selectable

option within a menu line.

•When no cursor displays, use the çand è

keys to scroll through various parameter

menu details given in the last three

configuration menu lines.

DATA ENTRY

Total & Harms Keys

The TOTAL key requests a total value of the

selected parameter item.

The HARMS key toggles the “bandwidth”

selection between AC+DC and a harmonic

range.

TOTAL

HARMS

20 6000-2 & -3 User Guide, Rev E

Numeric Entry Keys

These keys are part of the DATA ENTRY keypad:

•Use the numbered keys to enter numerical

data into the display.

•Use the –(minus sign) to enter negative

integers and to change negative integers to

positive, as required.

•Use the .(decimal point) to enter decimal

values.

•Use the m and Kkeys to designate “micro”

and “kilo”. Note that these keys become

disabled automatically when not applicable.

DATA ENTRY

.

-

0

CLEAR ENTER

Clear & Enter Keys

The CLEAR key is part of the DATA ENTRY

keypad and is used to:

•Discard changes made in either a menu line

or a menu.

•Abandon any change made, restarting the

selection from the beginning.

The ENTER key is part of the DATA ENTRY

keypad and is used to:

•Implement the action per the changes made

in either a menu line or a menu.

•Enter updated data into the menu settings.

DATA ENTRY

CLEAR ENTER

Store & Recall Keys

The STORE and RECALL keys are part of the

CONTROL keypad. These keys are used within

the Configuration Setup menus to:

•Store configurations in the internal non-

volatile “library” (65535 configurations).

•Recall any of the stored configurations.

•Overwrite and remove a configuration,

select or enter the number of an already

defined stored configuration.

Refer to Storing and Retrieving Configurations

on page 32.

SETUP

RECALL

STORE

CONTROL

PRINT

CAL

LOCAL

This manual suits for next models

1

Table of contents

Other Vitrek Measuring Instrument manuals

Vitrek

Vitrek 951i Installation and operation manual

Vitrek

Vitrek Xitron 2801 User manual

Vitrek

Vitrek 95 Series Installation and operation manual

Vitrek

Vitrek 4700 Operating instructions

Vitrek

Vitrek V4 User manual

Vitrek

Vitrek 4600A User manual

Vitrek

Vitrek 944i Installation and operation manual

Vitrek

Vitrek 930i Installation and operation manual

Vitrek

Vitrek XiTRON XT560 User manual

Vitrek

Vitrek Xitron 2553 Installation instructions