Contents

General .................................................................................................... 3

Specifications ......................................................................................... 5

Intakeand Exhaust System ..................................................................... 5

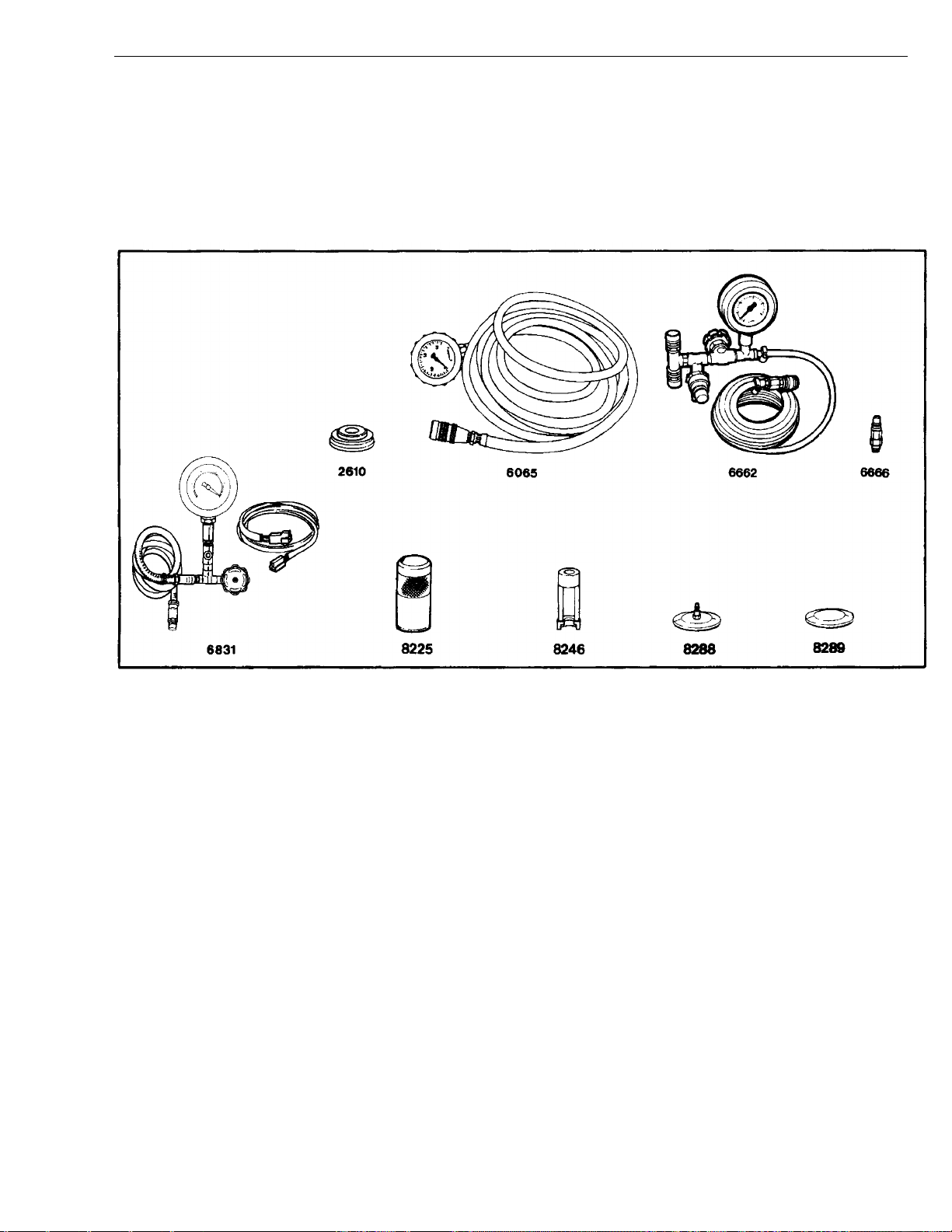

Tools ........................................................................................................ 7

Special Tools ......................................................................................... 7

Special Equipment ................................................................................. 8

Design and Function ............................................................................. 9

Intakeand Exhaust System ..................................................................... 9

Preheater ............................................................................................... 9

D12C ................................................................................................. 9

Engines without Preheater ................................................................ 10

Engine Brake....................................................................................... 11

D12C ............................................................................................... 12

Crankcase Ventilation .......................................................................... 18

D12C ............................................................................................... 18

Exhaust Pressure Governor ................................................................ 19

D12C ............................................................................................... 21

EPG Control Valve............................................................................ 22

D12A ............................................................................................... 22

D12B ............................................................................................... 22

Air Restriction Indicator ....................................................................... 23

Turbocharger ........................................................................................ 24

D12A ............................................................................................... 24

Exhaust Manifold ................................................................................. 25

Tightening Sequence ........................................................................ 26

Troubleshooting ................................................................................... 27

Air Restriction Indicator,Checking ...................................................... 27

Service Procedures ............................................................................. 29

Air Filter Element, Replacement ......................................................... 29

IntakeManifold Gasket(s), Replacement ............................................ 30

Removal .......................................................................................... 31

Installation ....................................................................................... 31

Turbocharger,Replacement ................................................................ 32

Removal .......................................................................................... 32

Installation ....................................................................................... 33

Exhaust Manifold Gasket(s), Replacement ......................................... 34

(Turbocharger Removed) ................................................................... 34

Exhaust Pressure Governor,Replacement ......................................... 35

Exhaust Pressure Governor,Overhaul ............................................... 36

(Unit Removed) ................................................................................. 36

Disassembly .................................................................................... 36

Assembly ......................................................................................... 37

Charge Air Cooler Leak Test, Checking .............................................. 39

System Check...................................................................................... 41

Boost Pressure,Checking ................................................................... 41

Exhaust Backpressure,Checking ........................................................ 42

Pressure Testing Outlet Location ...................................................... 42

Backpressure Measuring Techniques ............................................... 42

Feedback

Operation Numbers1