OSYWT225-EN

4/5

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

HANDLING & STORAGE

HANDLING

Do not drop or throw the product as it may break.

STORAGE

Store away from dust, moisture and direct sunlight.

If possible, store in the original package.

CHECKING

• Check the product code before installation.

• Make sure that the bolts are not loose.

HANDLING OF MANUAL OPERATION

• Be careful about temperature of a lever / handle part,

when using it for the fluid of the high temperature or

low.

• Avoid the operation with bare hands, and make a

protective measure.

• For manual operation, loosen the butterfly nut before

operating. After operation, tighten the butterfly nut to

secure the position.

INSTALLATION

PRECAUTIONS

• Flush the pipeline carefully before installing the

damper. Foreign particles, such as sand or pieces of

welding electrode, will damage the disk and seats.

• For dampers with specified flow direction (WT),

check the arrows on the product before piping.

• Damper is shipped closed. (allows quick piping.)

• Disc interference may also occur when damper is

installed in pipeline with smaller than normal inside

diameter such as thick wall pipe, or lining pipe.

Suitable corrective measurement must be taken

(taper boring the pipe or pipe liner, etc.)

PIPING FLANGES

• Gasket should be selected appropriately to suit the

fluid, pressure and temperature.

Use spring washer to prevent from decreasing

surface pressure gasket when the temperature

change happens frequently.

• Wafer type butterfly damper is put between two

seats of flanged-end and tightened with long bolts.

• Before bolts are tightened, damper should be

centered within the bolts to prevent possible disc

interference or damage by contact with the pipe or

flange.

• Tighten all bolts using crossover method to load the

joint evenly.

ENVIRONMENT

If there is a possibility that the fluid and drive part

freeze, please take measures to prevent freezing.

POSITIONING

Should be positioned through 90° upward from

horizontal. Provide space around the product to

allow manual operation, inspection and replacement

work.

INSULATION WORK

• For maintenance of gland packing, insulation should

be below the ground part.

• The upper part of the ground plate part is a heat

dissipation part, do not insulate it.

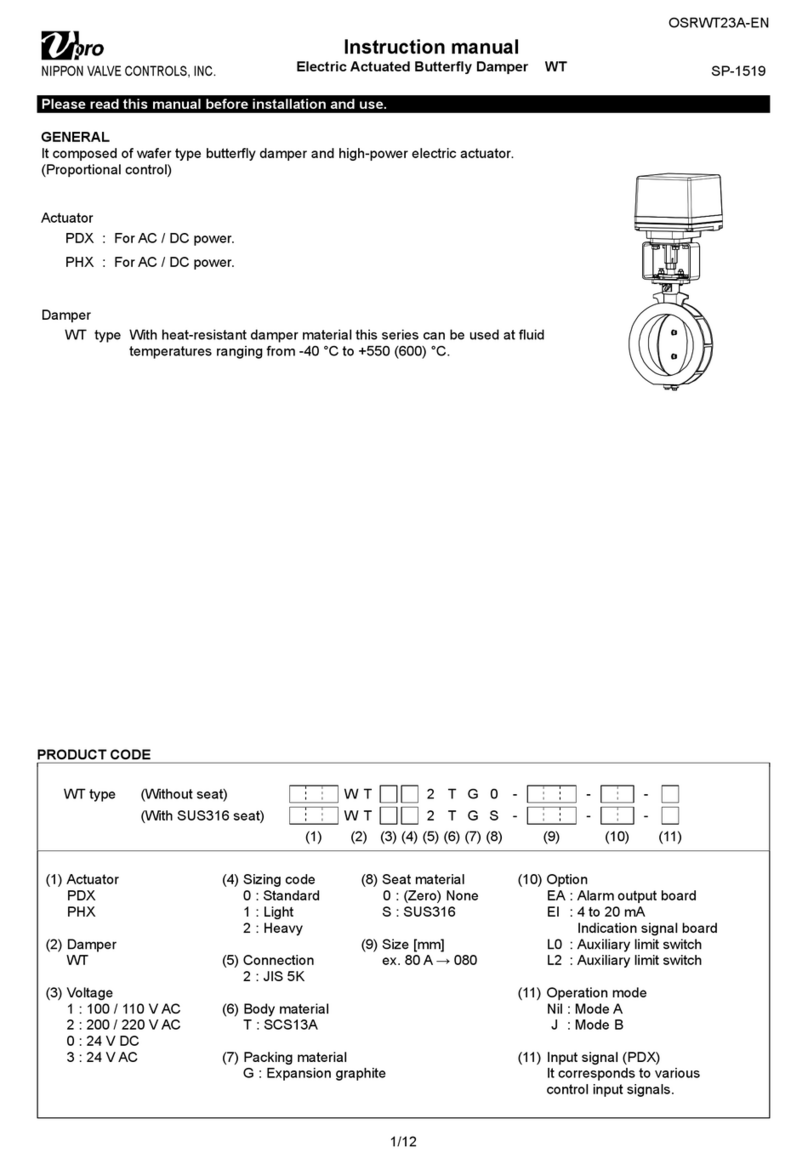

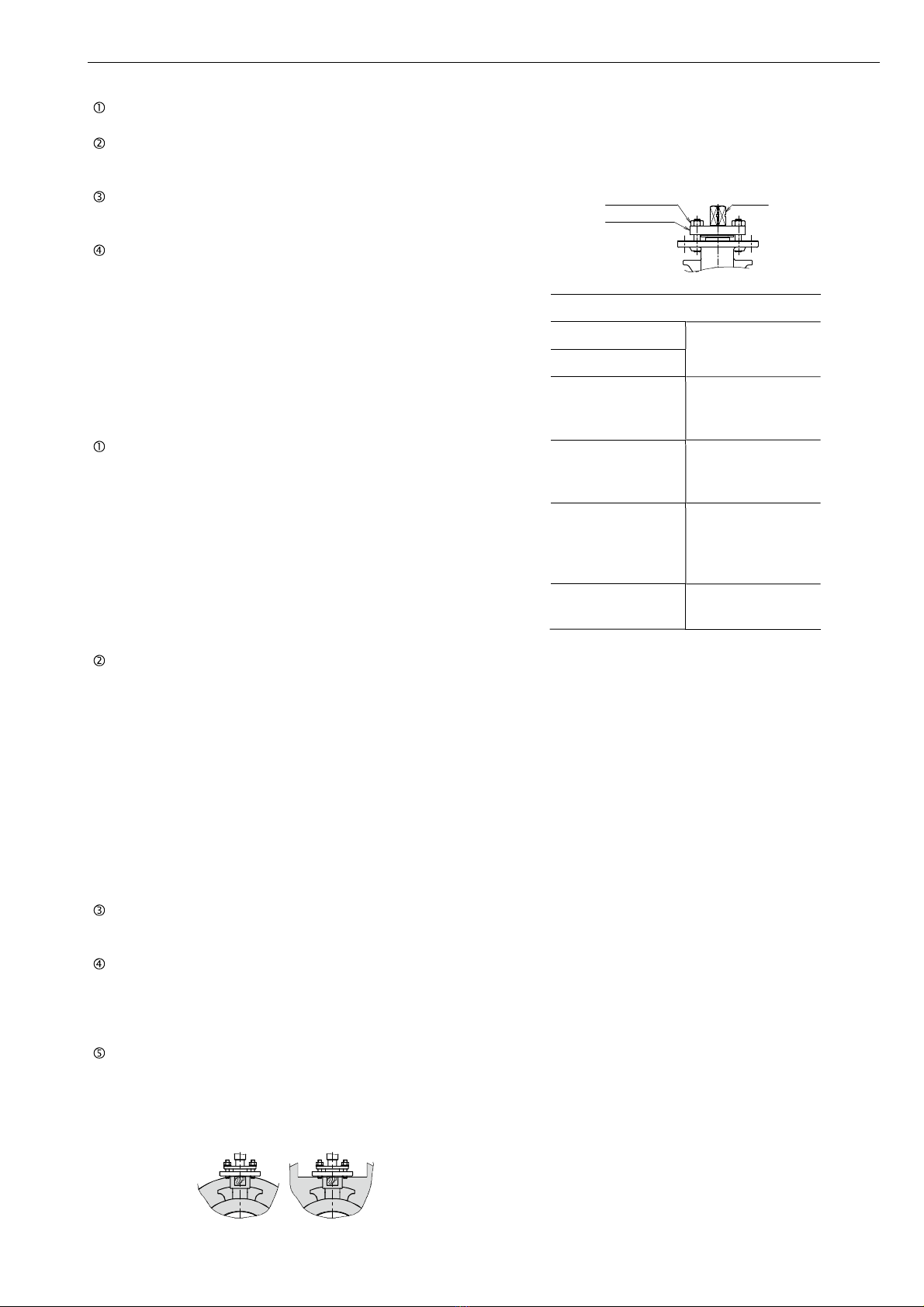

TIGHTEN THE GLAND NUTS

• Check that there is no leakage from the gland

packing.

• If it leakage, tighten gland nuts by alternately.

Do not over-tighten the gland nuts.

Recommended torques

Damper size [mm] Torque [Nm]

WT

040

050

065

1

080

100

125

2

150

200

250

300

5

350

400 8

MAINTENANCE

Do the routine maintenance at least once in half a

year.

Inspection items

• Confirm operation of opening and closing.

• Confirm whether screws are loose or not.

• Confirm the fluid temperature or pressure.

• Confirm the leak from damper stem.

• Confirm the bolt tightening torque.

Gland nut

Gland plate

Stem