—3 —

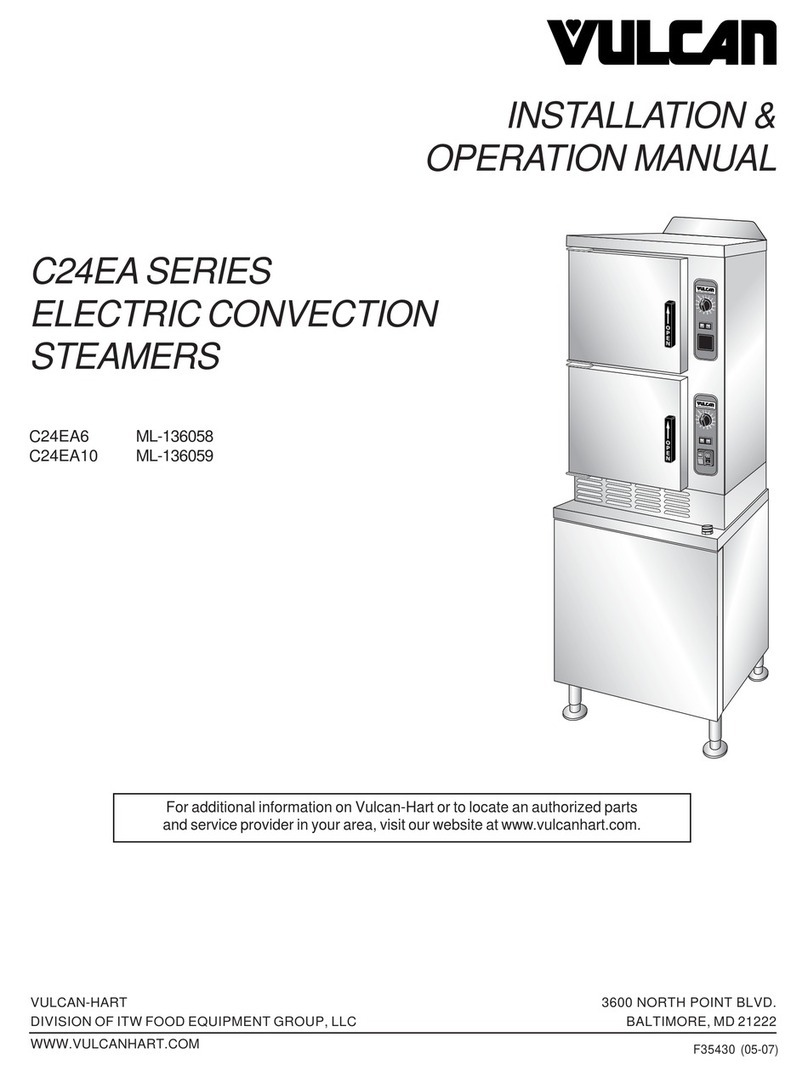

C24EA SERIES ELECTRIC CONVECTION STEAMERS

INTRODUCTION

GENERAL

Vu can convection steamers are produced with

qua ity workmanship and materia . Proper insta ation,

usage and maintenance wi resu t in many years of

satisfactory performance. It is suggested that you

thorough y read this entire manua and carefu y

fo ow a of the instructions provided.

The C24EA6 and C24EA10 convection steamers

are dua compartment, e ectric, pressure ess

steam cookers with an interna e ectric steam

generator that maintains water temperature at

approximate y 195° F. At 208V and 480V, the

C24EA6 is rated at 17.2kW, and the C24EA10 is

rated at 25.6kW. At 240V, the C24EA6 is rated

at 19.7kW, and the C24EA10 is rated at 26.4kW.

Mode C24EA6 can accommodate three 2 1/2" deep

(6.4 cm) steam pans per compartment. Mode

C24EA10 can accommodate five 2 1/2" deep (6.4

cm) steam pans per compartment. The C24EA6

and C24EA10 e ectric convection steamers are

designed for cooking vegetab es, eggs and other

foods, in commercia kitchens. Each compartment

has a 0-60 minute timer, as we as a constant steam

feature. The buzzer requires manua shutoff. The

steamer is equipped with a cabinet base with f anged

feet for f oor mounting.

INSTALLATION

Before insta ing, verify that the e ectrica supp y

agrees with the specifications on the data p ate

ocated on the front of the machine. If the supp y

and equipment requirements do not agree, do

not proceed with the insta ation. Contact your

dea er or Vu can-Hart immediate y.

This unit is shipped pre-wired for 208/60/3 or

480/60/3. 240V and sing e-phase operation

require changes to the heater connection 240/

60/3, 240/60/1 and 208/60/1. This unit wi operate

at 60Hz or 50Hz. Conversions must be made by

a Vu can Hart authorized service technician.

UNPACKING

This steamer was inspected before eaving the

factory. The transportation company assumes

fu responsibi ity for safe de ivery upon

acceptance of the shipment.

Immediate y after unpacking, check for possib e

shipping damage. If steamer damage is found,

save the packaging materia and contact the

carrier within 15 days of de ivery.

INSTALLATION CODES AND

STANDARDS

In the United States of America:

1. State and oca Codes

2. Nationa Fue Gas Code, ANSI/z223.1/NFPA

#54( atest edition). Copies may be obtained

from The American Gas Association,

Accredited Standards Committee Z223@

400 N. Capita St. NW, Washington D.C.

2001 or the Secretary Standards Counci ,

NFPA, 1 Batterymarch Park, Quincy MA

02169-7471.

No e: In the Commonwea th of Massachusetts:

A gas app iances vented through a venti ation

hood or exhaust system equipped with a damper

or with a power means of exhaust sha comp y

with 248 CMR.

3. Vapor Remova from Cooking Equipment,

NFPA#96 ( atest edition).

4. Copies may be obtained from The Nationa

Fire Protection Association, 1 Batterymarch

Park, Quincy MA 02169-7471.

5. Nationa E ectrica Code, ANSI/NFPA-70

( atest edition). Copies may be obtained

from The Nationa Fire Protection

Association, 1 Batterymarch Park, Quincy

MA 02169-7471.

In Canada, the steamer must be insta ed in

accordance with:

1. Loca codes.

2. Canadian E ectrica Code (CSA C22.2 No.3,

atest edition) avai ab e from the Canadian

Standards Association, 5060 Spectrum Way,

Mississauga, Ontario, Canada L4W 5N6.