MIO-R45XRDR19061B Rev C

G&B Specialties Inc. 535 West 3rd Street, Berwick, PA, USA Tel: (570) 752-5901 Fax: (570) 752-6397

US Field Service: 570-441-6988; CAN Field Service 570-854-0482; www.rafna.com

-3-

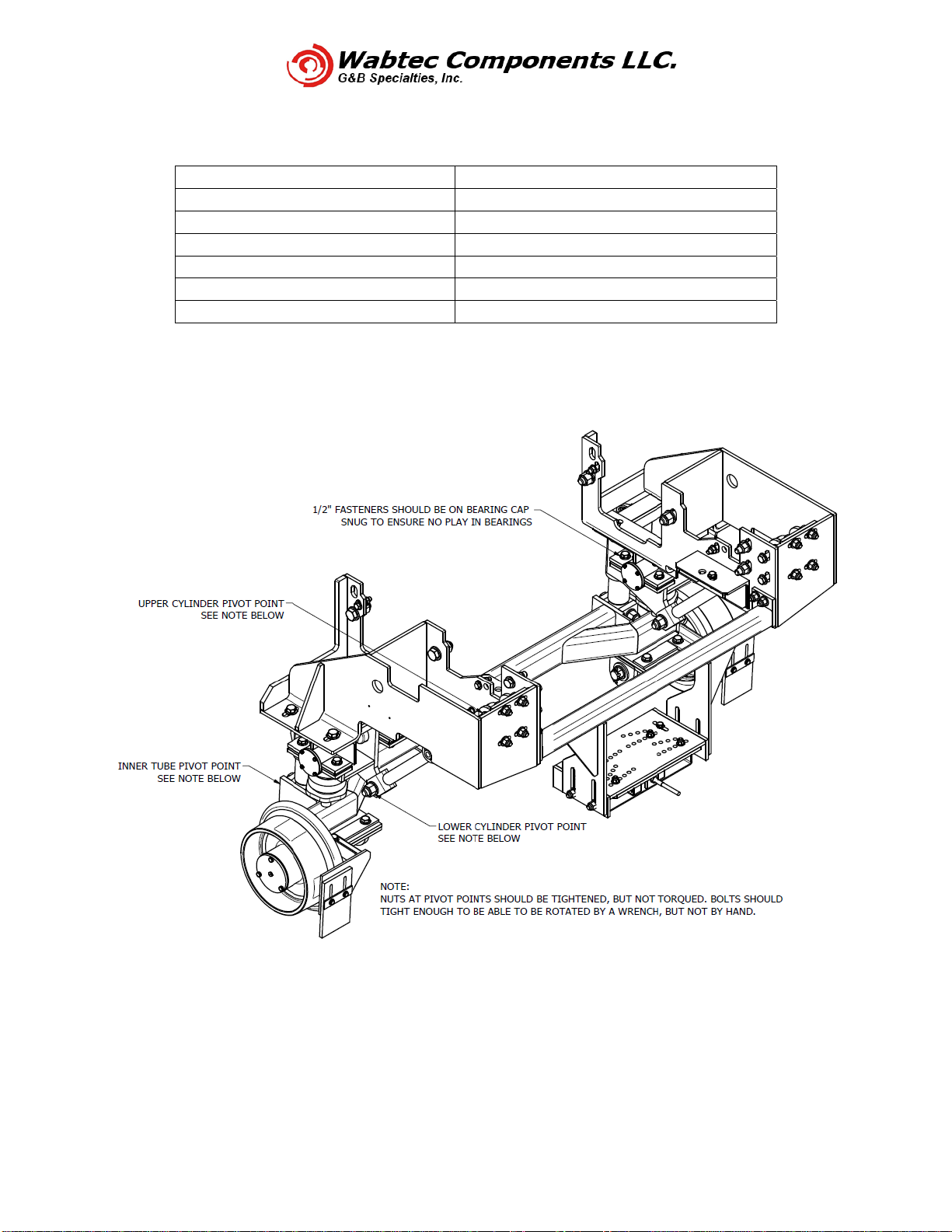

INSTALLATION OF REAR RAILGEAR KIT

1. To install the railgear at the correct height, ensure that the vehicle is resting on its six

properly inflated tires. Remove tail lights.

2. Position and support the railgear so that the railgear mounting boxes are on either side of

the rear of the vehicle frame with the blind end of the hydraulic cylinders facing the rear

of the vehicle. The mounting boxes should be flush with the rear and top surface of the

vehicle frame (as a starting point) and fit around the vehicle’s suspension hangers. The

holes in the mounting boxes should align with existing holes in the rear of the vehicle

frame. It may be necessary to loosen or remove the fasteners that support the railgear

axle lock system to be able to fit the railgear on the frame. Once the railgear is on the

frame, tighten and torque the 1/2” fasteners securing the railgear lock system to the

railgear to 100 ft-lbs dry. Do not over torque.

3. Ensure that there is approximately 21.5” between the railgear-to-mounting box interface

and the ground as shown in Figure 1. The slots in the mounting boxes will allow for

approx. 1/4” of vertical adjustment, either up or down. If the 21.5” mounting height

cannot be achieved, the vehicle suspension will need to be modified. This modification is

not included with the RAFNA railgear.

4. Fasten each railgear mounting box to the vehicle frame using two 5/8” x 2” long bolts,

four 5/8” washers and two 5/8” nuts through the existing frame holes at the rear as

shown.

5. Repeat step four for two 7/16” x 1 3/4” long bolts, washer and nuts through the existing

frame holes as shown.

6. Using the front-most bottom holes in each railgear mounting box as a guide, drill a 25/32”

hole through the vehicle frame.

7. Fasten each railgear mounting box to the vehicle frame using through the drilled hole

using 3/4” supplied hardware as shown.

8. Using the center hole in each railgear mounting box as a guide, repeat steps 6 and 7.

9. Fasten each rear support bracket to each railgear mounting box using two 1/2” x 1.75”

long bolts, four 1/2” washers and two 1/2” nuts. Slide support bracket up until the top of

the bracket is resting on the bottom of the truck frame. Torque the 1/2” fasteners to 100

ft-lbs dry. Do not over torque.

10. Torque the 5/8” fasteners to 150 ft-lbs dry and the 3/4” fasteners to 175 ft-lbs dry. Do

not over torque.

11. Place the rail wheels below the mounting tables on the railgear axle. Place the rail

sweeps to the rear of the rail wheels and on top of the mounting tables. Fasten the rail

wheels and rail sweeps to the mounting tables with eight 1/2” x 2.25” long bolts, sixteen

1/2” washers and eight 1/2” nuts.