POW-R-DRIVE II

6

For your safety and the safety of others, read and

understand these safety recommendations and op-

erating instructions before operating.

SECTION III SAFETY INSTRUCTIONS

The E. H. Wachs Company takes great pride in

manufacturing safe, quality products with user safety

a priority.

The E.H. Wachs Company recommends that all users

comply with the following safety rules and instructions

when operating our equipment.

Read the Following thor-

oughly before proceeding.

WARNING

Impact resistant eye protection

must be worn while operating or

working near this tool.

For additional information on eye and face protection, re-

fer to federal OSHA regulations, 29 Code of Federal Regu-

lations, Section 1910.133., Eye and Face Protection

and American National Standards Institute, ANSI Z87.1,

Occupational and Educational Eye and Face Protection.

Z87.1 is available from the American National Standards

Institute, Inc., 1430 Broadway, New York, NY 10018.

Hearing protectors are required in high noise areas, 85

dBA or greater. The operation of other tools and equip-

ment in the area, reflective surfaces, process noises and

resonant structures can substantially contribute to and in-

crease the noise level in the area. For additional informa-

tion on hearing protection, refer to federal OSHA regula-

tions, 29 Code of Federal Regulations, Section 1910.95,

Occupational Noise Exposure and ANSI S12.6 Hearing

Protectors.

CAUTION

Personal hearing protection is rec-

ommended when operating or

working near this tool.

Some individuals are susceptible

to disorders of the hands and arms

when exposed to tasks which in-

volve highly repetitive motions and/

or vibration. Disorders such as Carpal tunnel syn-

drome and tendonitis can be caused or aggravated

by repetitious, forceful exertions of the hands and

arms.

CAUTION

• Use minimum hand grip force.

• Keep wrists straight.

• Avoid prolonged, continuous vibration exposure.

• Avoid repeated bending of wrists and hands.

• Keep hands and arms warm and dry.

ALWAYS WEAR PROTECTIVE EQUIPMENT:

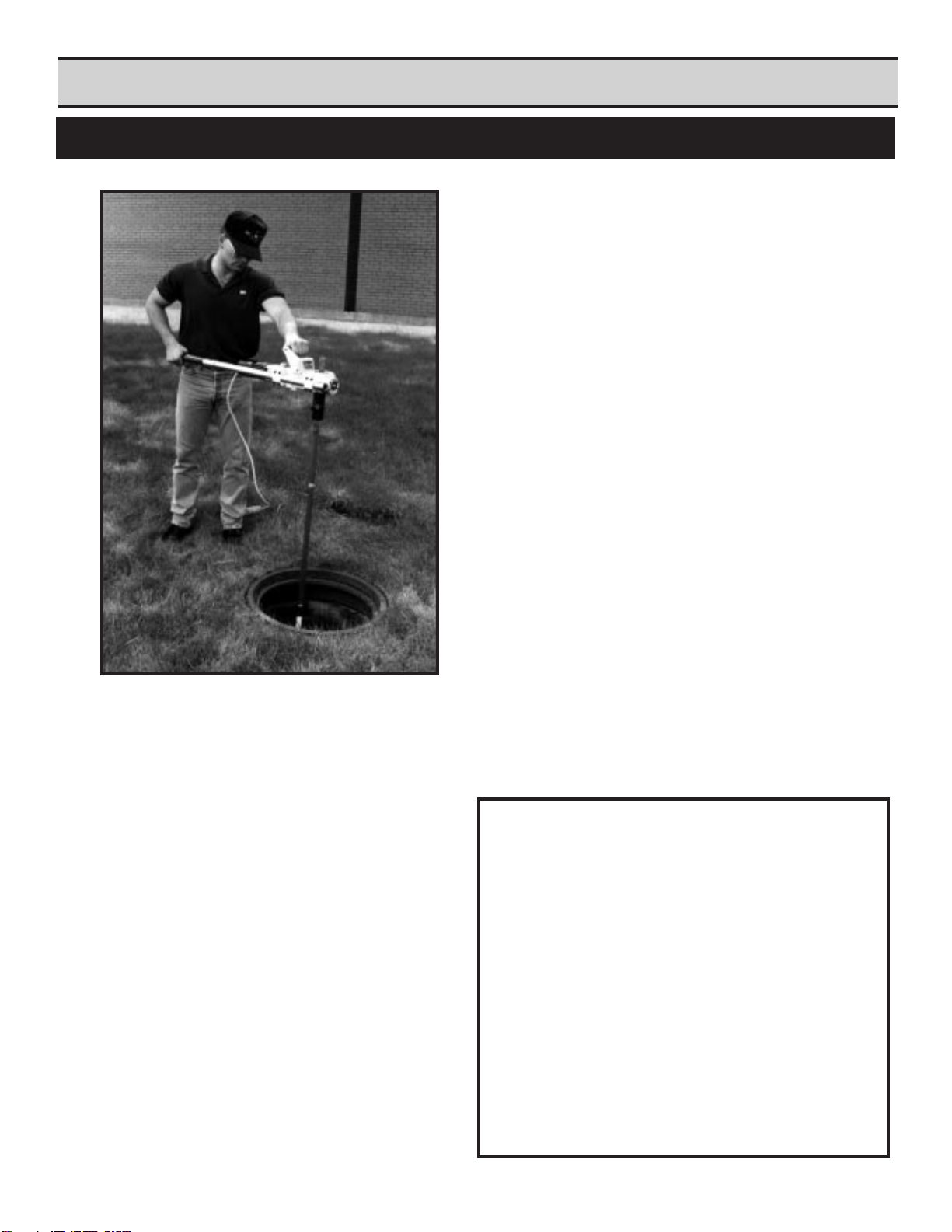

1. READ THE OPERATING MANUAL!! Reading the setup

and operating instructions prior to beginning the setup proce-

dures can save valuable time and help prevent injury to opera-

tors or damage to machines.

2. INSPECT MACHINE & ACCESSORIES! Prior to machine

setup physically inspect the machine and it's accessories. Look

for loose bolts or nuts, lubricant leakage, excessive rust, etc. A

properly maintained machine can greatly decrease the chances

for injury.

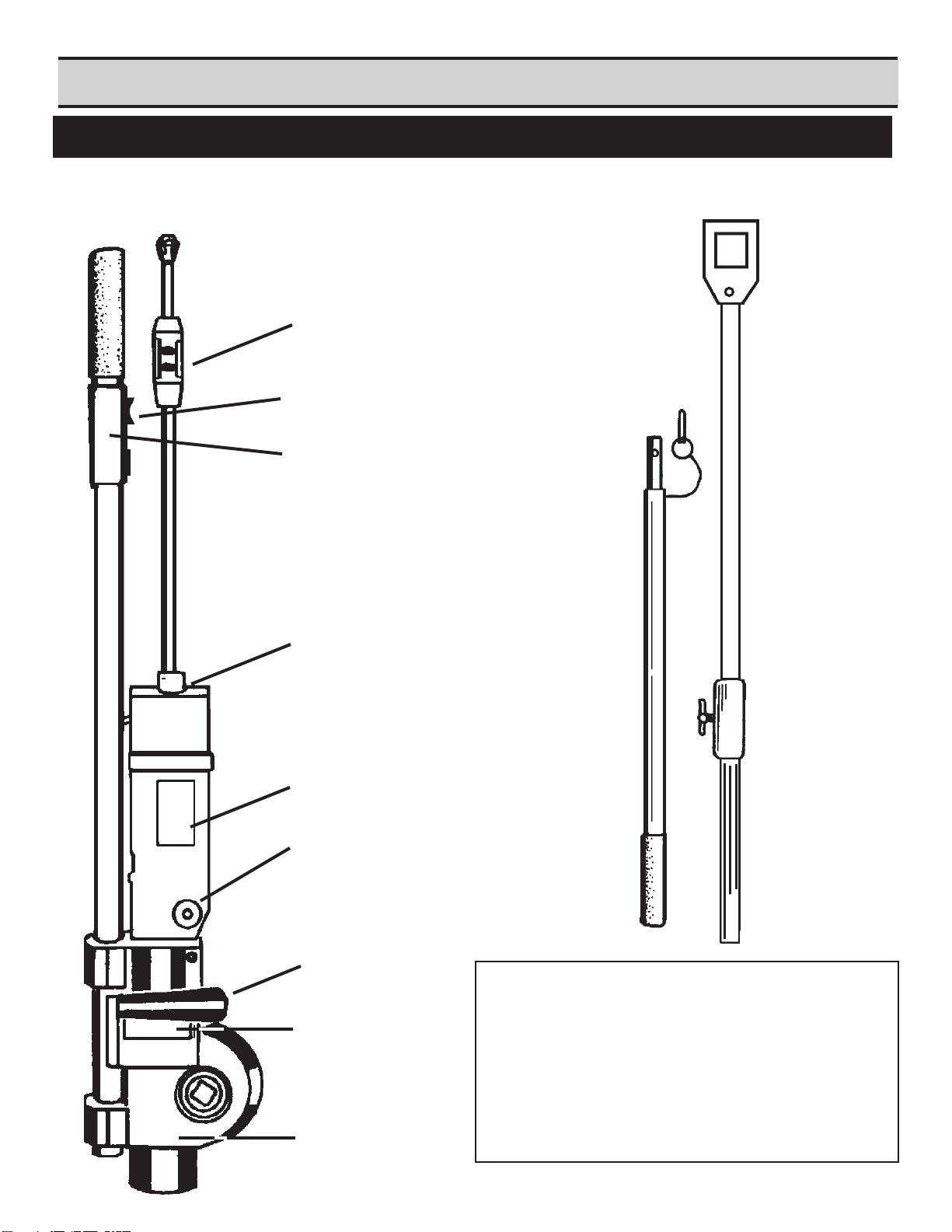

3. ALWAYS READ PLACARDS & LABELS! All placards, la-

bels and stickers must be clearly legible and in good condition.

Replacement labels can be purchased from the manufacturer.

4. KEEP CLEAR OF ROTATING PARTS! Keep hands, arms

and fingers clear of all rotating or moving parts. Always turn

machine off before attempting any adjustments requiring con-

tact with the machine or it's accessories.

5. SECURE LOOSE CLOTHING & JEWELRY! Loose fitting

clothing, jewelry; long, unbound hair can get caught in the

rotating parts on machines. By keeping these things secure or

removing them you can greatly reduce the chance for injury.

6. KEEP WORK AREA CLEAR! Be sure to keep the work area

free of clutter and nonessential materials. Only allow those

personnel directly associated with the work being performed to

have access to the area if possible.

Keep clear of rotating parts during opera-

tion. Hands and arms should be kept a

minimum of 2’ away from moving parts

exept during starting and stopping.

CAUTION

Users of the electric powered Pow-

R-DriveII Valve Operator should

avoid standing water whenever

possible. Do not expose electrical cord to water as

this may result in electrical shock.

CAUTION