Contents

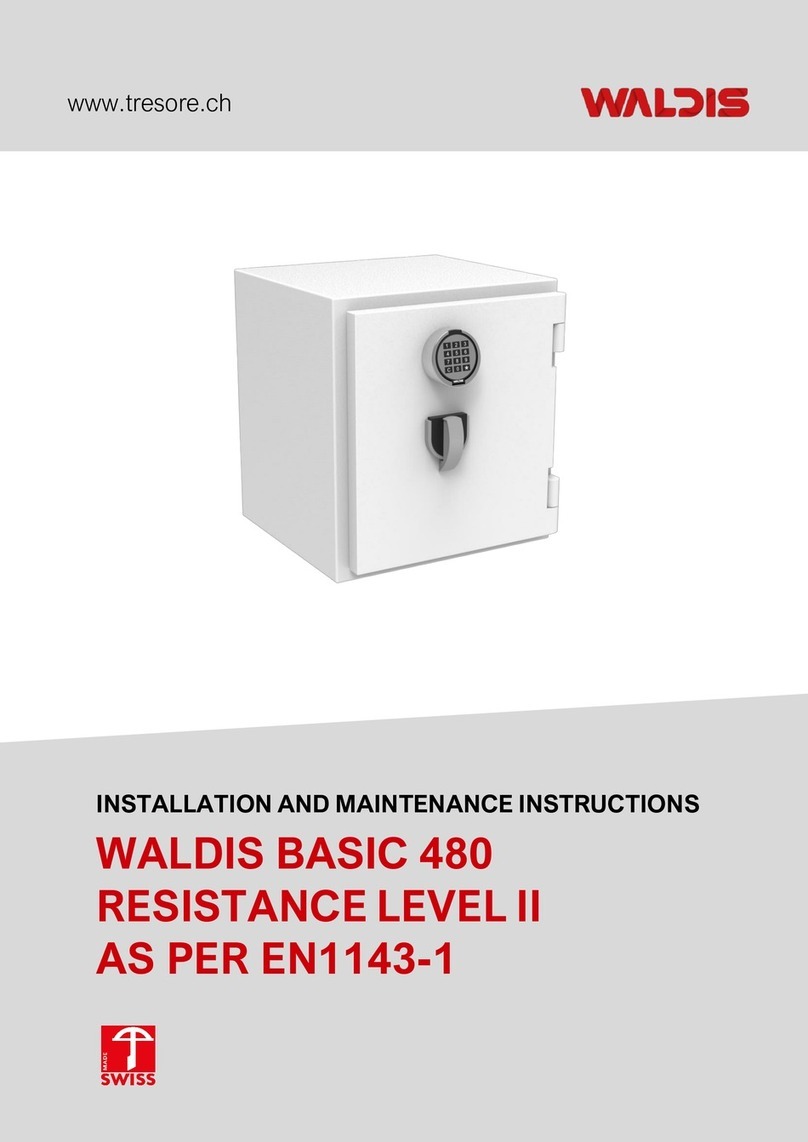

1. General information ...................................................................................................................1

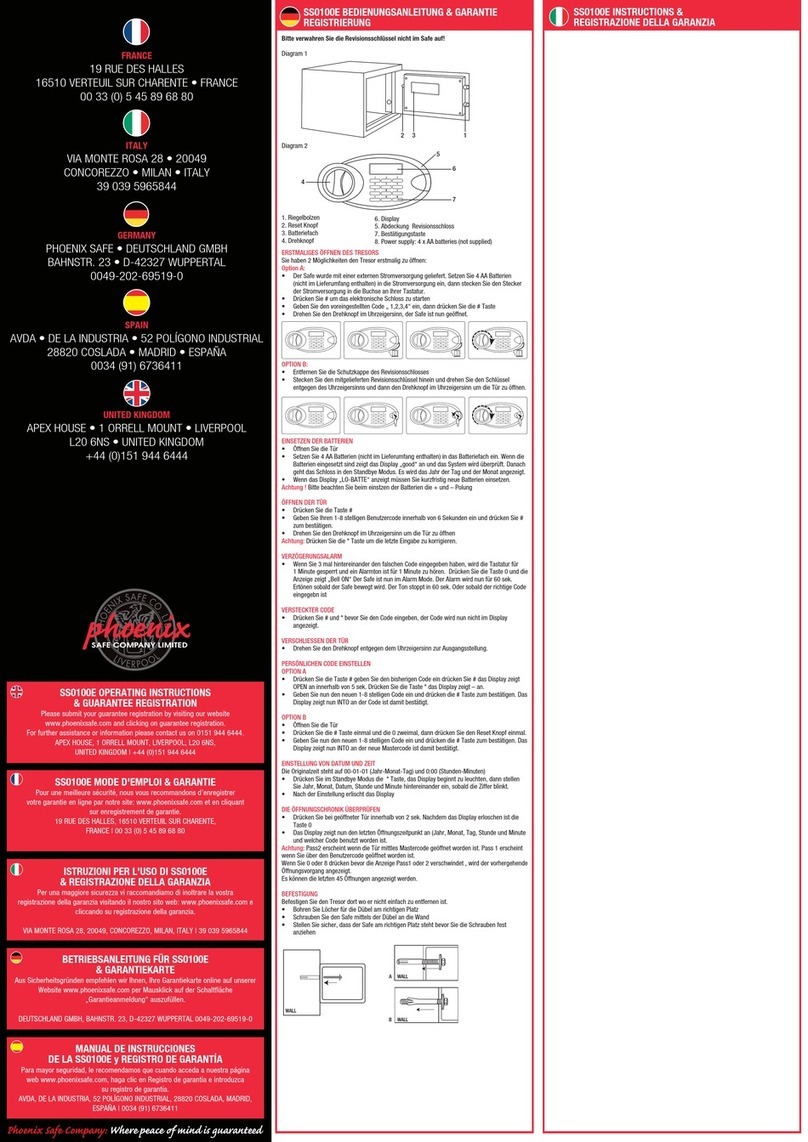

1.1. Safety instructions ..............................................................................................................1

1.2. Table of weights ..................................................................................................................1

1.3. Regulations and insurance ................................................................................................2

1.4. operating elements.............................................................................................................2

1.5. Set-up ...................................................................................................................................2

2. Installation....................................................................................................................................3

2.1. Positioning against the building wall ................................................................................3

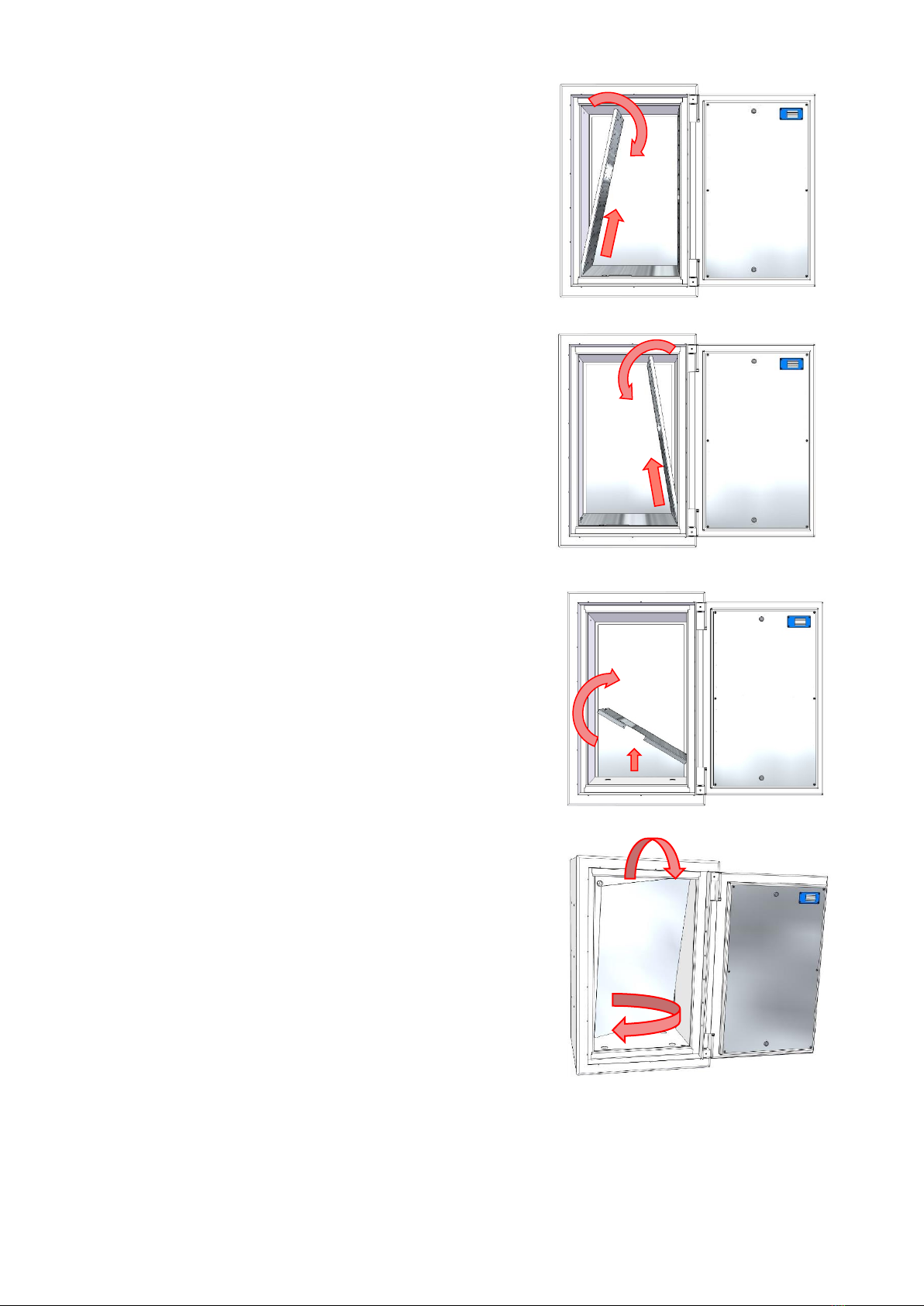

2.2. Disassembly, interior construction ...................................................................................4

2.3. Anchoring the safe..............................................................................................................6

2.3.1. Important prior clarification ........................................................................................6

2.3.2. Preparing the safe .......................................................................................................6

2.3.3. Table for dimensions, anchoring holes ....................................................................7

2.3.4. Procedure .....................................................................................................................8

2.4. Assembly, interior construction ........................................................................................9

2.5. Cable entry / power connection .................................................................................... 11

3. Maintenance and care instructions ...................................................................................... 12

4. Exemption from liability .......................................................................................................... 12

5. Guarantee against theft .......................................................................................................... 13