Introduction

[M2001452_0] - EN / 22.06.12 Page 4 of 20 Subject to change without notice

1.3 Important safety information

The safety instructions and warnings described here are

intended to safeguard your health as well as protect the

product. Please read the following points carefully.

Damage resulting from inappropriate use or the failure to

observe these instructions or safety information is not

covered by the guarantee. Liability will not be accepted

for secondary damage.

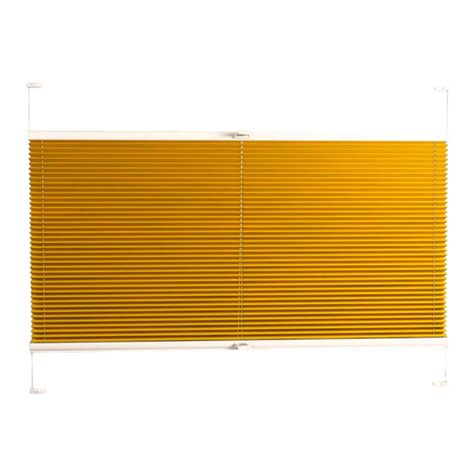

General conditions

If the external venetian blind with auxiliary motor and bat-

tery-operated emergency retraction set is used at escape

doors and emergency windows to protect against sum-

mer heat and glare and to provide privacy, the battery-

operated emergency retraction set is activated in case of

an emergency to clear the escape route.

Correct functioning of the external veneti-

an blind with auxiliary motor and battery-

operated emergency retraction set and,

therefore, unblocking of the escape doors

and emergency windows in case of an

emergency are only ensured if you follow

our safety instructions closely.

Danger to life and limb if the WAREMA

control is not used!

It must be ensured that the external venetian

blind is only activated by the associated

electronic battery-operated control. Mani-

pulations by third parties must be

excluded. It is important that the external

venetian blind is not blocked by dirt or

obstacles.

Danger to life and product damage from

incorrect procedure during commission-

ing! If the following points are not followed,

no warranty can be granted for functional

problems, soiling and damage.

The external venetian blind must remain

out of service until the commissioning has

been released.

Raise the external venetian blind fully to

clear the escape route. The external ve-

netian blind is sufficiently raised if the ex-

ternal venetian blind disappears into the

cover panel (if present), or if the escape

door or emergency window can be ope-

ned.

Installation preparations

Danger to life from restrictions of the escape

route while during installation of the external

venetian blind with auxiliary motor and bat-

tery-operated emergency retraction set! Befo-

re beginning installation, inform the safety

officer that the escape route is available only

to a limited extent. It must be ensured that the

building can be evacuated along a different

escape route.

Risk of injury and damage to the product

from incorrect installation!

Comply with the specified installation

steps and instructions.

Install the product only if it is in technically

perfect condition.

Before installation, check the mounting

substructure to make sure it can bear the

loads.

Widely cordon off the installation site and

the projection area of the external veneti-

an blind.

Packaging

Risk of suffocation! Do not leave the packa-

ging material lying around, and keep children

away from small parts. Plastic film, polystyre-

ne, small parts, etc., can be very dangerous

for children to play with.

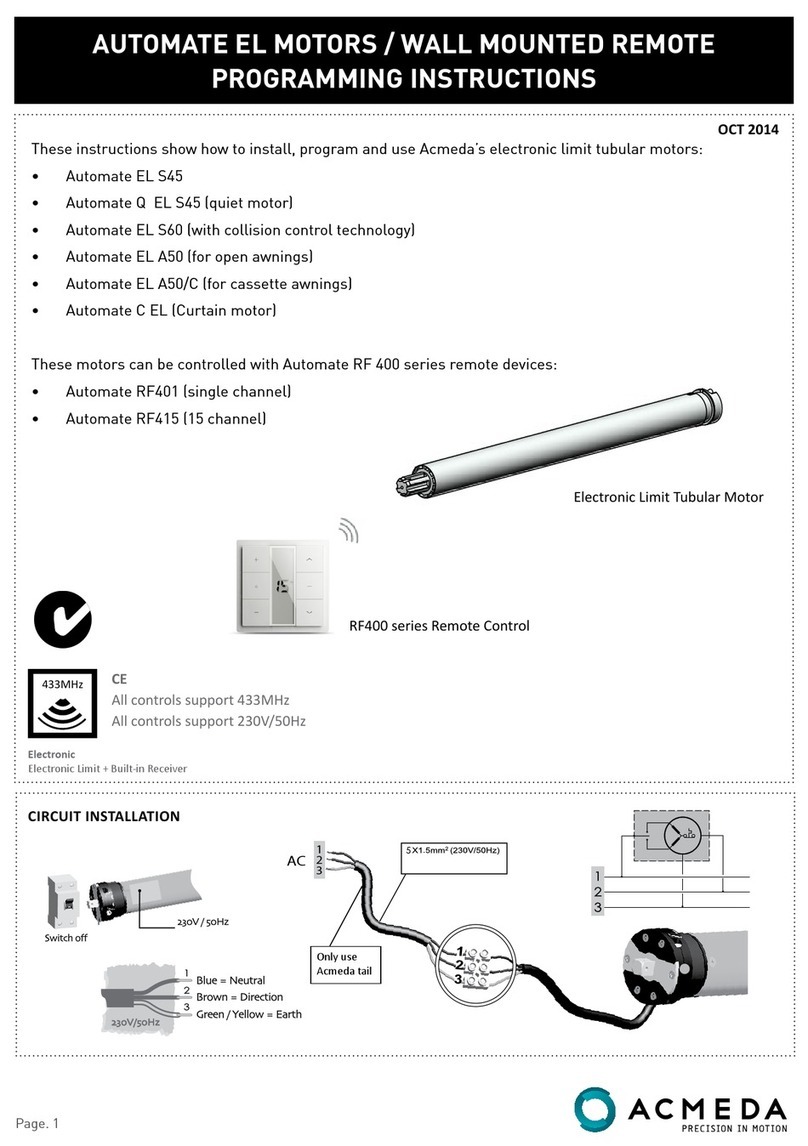

Electrical connection

Electric shock from incorrect installation!

The electrical installation must be performed

by a certified electrician in accordance with

the electrical installation regulations published

by the Association of German Electrical Engi-

neers (VDE 0100) or the standards and regu-

lations of the country in which the product is

being installed. The specialist must observe

the installation instructions included with the

electrical appliances. Before commissioning

the product, remove all lines that are not re-

quired. Disconnect any devices that are not

needed for operation.