Contents

1 Features.......................................................................................................................................4

2 Safety Symbo s used in this Manua .............................................................................................4

3 Safety Guide ines.........................................................................................................................5

3.1 Potentia Dangers.................................................................................................................................. 5

4 Responsibi ity for Operation or Damage.......................................................................................6

5 App ication....................................................................................................................................6

6 Before Starting............................................................................................................................. 7

6.1 Transport............................................................................................................................................... 7

6.2 Insta ation............................................................................................................................................. 7

6.3 Storage.................................................................................................................................................. 8

7 Insta ation/ Start-up.....................................................................................................................8

7.1 Location................................................................................................................................................. 8

7.2 F ushing-water Connector...................................................................................................................... 8

7.3 Drain Hose............................................................................................................................................. 9

8 Assemb y.................................................................................................................................... 10

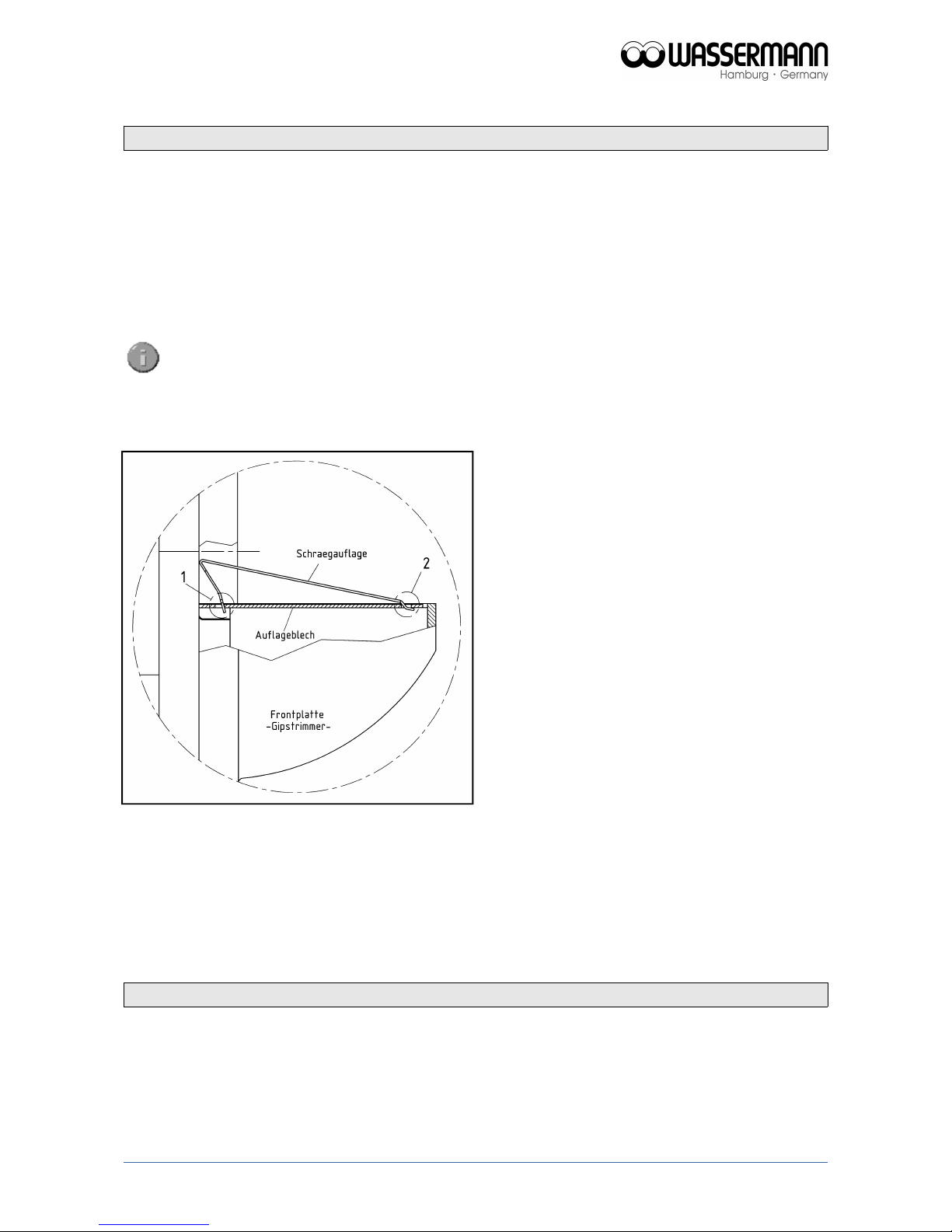

8.1 Insta ing the Ang ed Mount.................................................................................................................. 10

9 Supports..................................................................................................................................... 10

10 Operation.................................................................................................................................. 11

10.1 Genera Operating Instructions..........................................................................................................11

10.2 Water Regu ation............................................................................................................................... 11

11 Troub eshooting........................................................................................................................ 12

12 Care and Maintenance.............................................................................................................13

12.1 C eaning............................................................................................................................................ 13

12.2 Maintenance...................................................................................................................................... 13

12.3 Repairs.............................................................................................................................................. 14

12.4 Spare Parts........................................................................................................................................ 14

12.5 Service Hot ine 0049 (0)40 730 926 -20/ -24.....................................................................................14

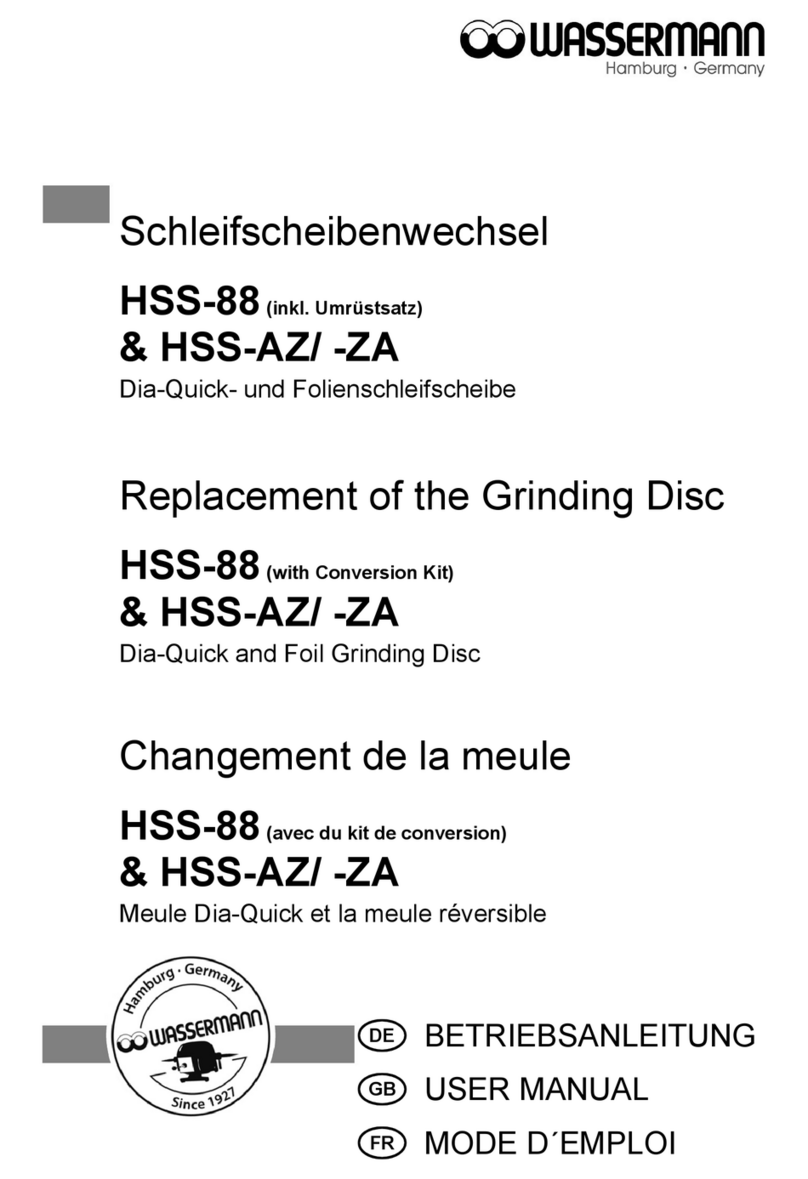

12.6 Spare Grinding Discs.........................................................................................................................14

12.7 Scope of De ivery/ Accessories.........................................................................................................15

12.8 Grinding Disc Overhau ...................................................................................................................... 15

12.9 Warranty............................................................................................................................................ 16

13 Technica Data..........................................................................................................................16

14 Disposing of the Unit................................................................................................................17

14.1 Information on Disposa for Countries within the EU.........................................................................17

15 EU Dec aration of Conformity...................................................................................................18