50 Hanover Road, Florham Park, New Jersey 07932 www ascovalve com

Page 2 of 3 I&M No V7506

Causes of Improper Operation

SIncorrect Pressure: Check valve pressure. Pressure to valve must

be within range specified on nameplate.

SExcessive Leakage: Disassemble valve and clean all parts. If parts

are worn or damaged, install a complete ASCO Rebuild Kit.

Valve Disassembly

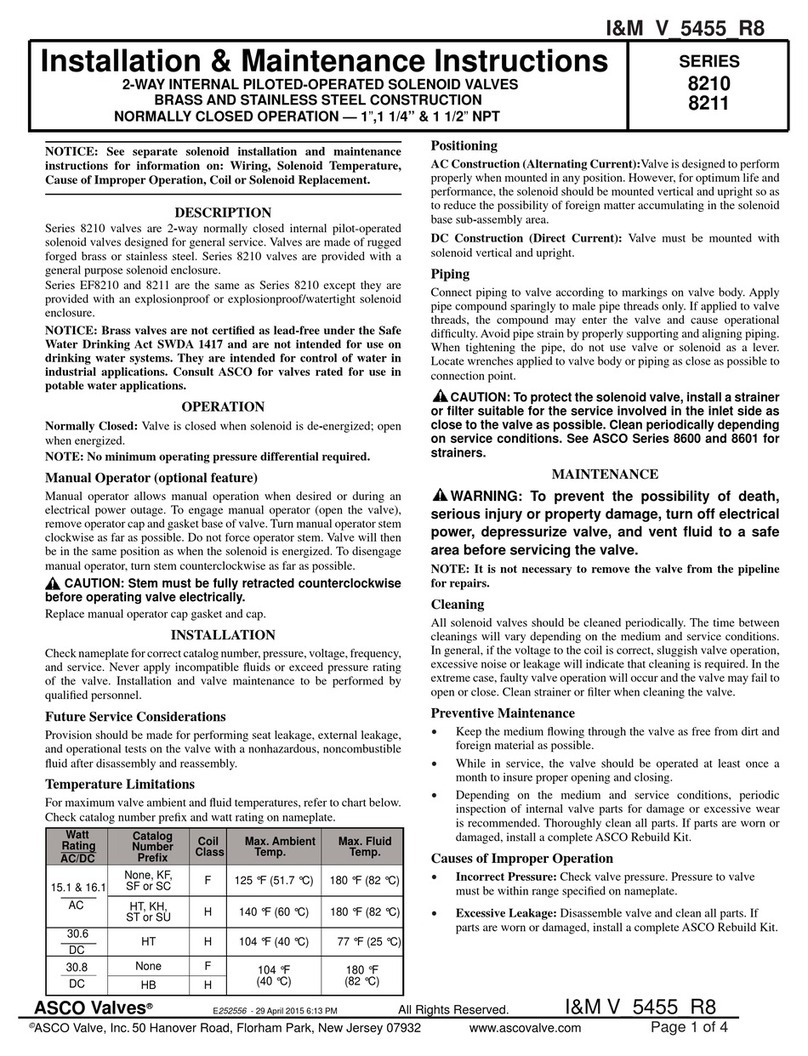

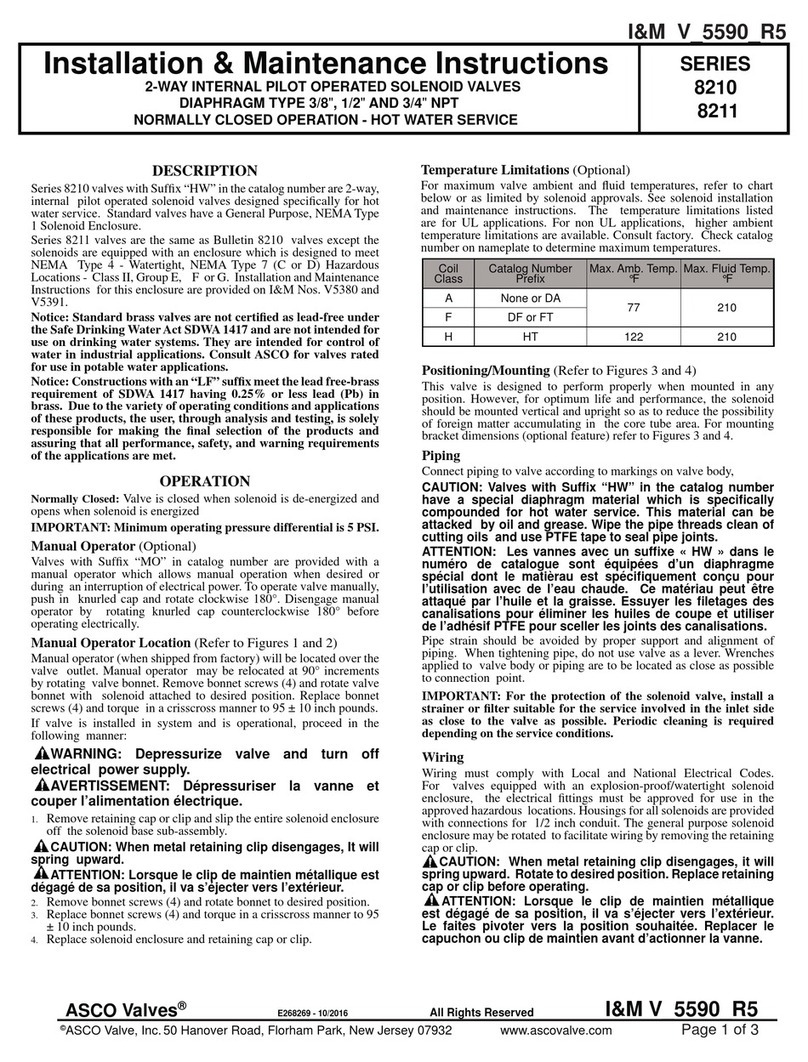

1. Disassemble valve in an orderly fashion using exploded views

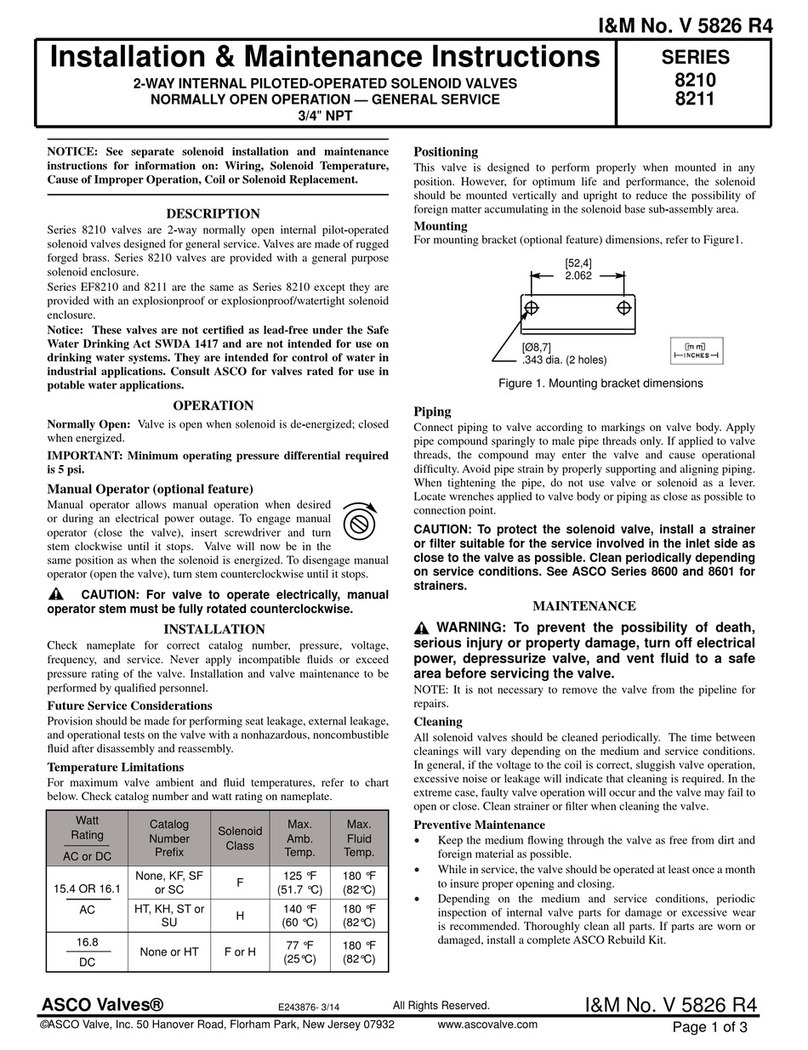

for identification and placement of parts. Refer to Figure 1 for

AC construction; Figure 2 for DC construction. For 1I or 1 ¼I

NPT valve construction, see Figure 1; for 1 ½I NPT valve

construction, see Figure 2.

2. Remove solenoid enclosure. See separate instructions.

SFor valves supplied with optional manual operators, see section on

Disassembly of Manual Operator.

3. Unscrew solenoid base sub-assembly from valve body. Then

remove core assembly with core spring and solenoid base

gasket.

4. For normal maintenance (cleaning) it is not necessary to

remove the valve seat. However, for valve seat removal use a

7/16I thin wall socket wrench

5. Remove bonnet screws, valve bonnet, diaphragm spring,

diaphragm assembly, body gasket, body passage eyelet (present

on current valve constructions only) and body passage gasket.

6. All parts are now accessible for cleaning or replacement. If

parts are worn or damaged, install a complete ASCO Rebuild

Kit.

- Service Notice -

When installing a new SCO Rebuild Kit, please be aware that the

diaphragm assembly may not be identical to the diaphragm

assembly in the valve. See Figure 1 for alternate diaphragm

constructions. The two diaphragm constructions are

interchangeable and will perform equally well.

CAUTION: To ensure proper valve operation, install all

parts supplied in ASCO Rebuild Kit. Do not mix old and new

parts.

Valve Reassembly

1. Lubricate body gasket, body passage gasket, bonnet gasket and

solenoid base gasket with DOW CORNINGr 200 Fluid

lubricant or an equivalent high-grade silicone fluid.

2. Install body passage gasket, body passage eyelet, diaphragm

assembly, diaphragm spring, valve bonnet and bonnet screws.

Hand thread screws as far as possible. Then torque bonnet

screws in a crisscross manner to 144 ± 15 in-lbs [16,3 ± 1,7

Nm].

3. If removed, install valve seat in valve body. Apply a small

amount of thread compound compatible with valve media to

valve seat threads. Torque valve seat to 75 ± 10 in-lbs

[8,5 ± 1,1 Nm].

SFor valves supplied with optional manual operator, see section on

Reassembly of Manual Operator.

4. For AC/DC construction (Figure 1), install core assembly with

core spring.

5. Install solenoid base gasket, core assembly with core spring and

solenoid base sub-assembly in valve body. Torque solenoid

base sub-assembly to 175 ± 25 in-lbs [19,8 ± 2,8 Nm].

6. Install solenoid. See separate instructions.

WARNING: To prevent the possibility of death,

serious injury or property damage, check valve for

proper operation before returning to service. Also

perform internal seat and external leakage tests with

a nonhazardous, noncombustible fluid.

7. Restore line pressure and electrical power supply to valve.

8. After maintenance is completed, operate the valve a few times

to be sure of proper operation. A metallic click indicates the

solenoid is operating.

Disassembly of Manual Operator

1. Unscrew solenoid base sub-assembly from manual operator

body.

2. Unscrew manual operator body from valve body. Then remove

stem retainer from base of manual operator body and

stem/spacer sub-assembly.

3. Pull stem/spacer sub-assembly with stem gasket from side of

manual operator body. Then remove core assembly with core

spring, solenoid base gasket and manual operator bonnet

gasket.

4. For further disassembly refer to section on Valve Disassembly

step 4.

Reassembly of Manual Operator

1. Lubricate stem gasket with DOW CORNINGr 111

Compound lubricant or an equivalent high-grade silicone

grease.

2. For AC/DC construction (Figure 1), install core assembly with

core spring.

3. Holding the manual operator body in a horizontal position,

install core assembly with core spring from the bottom end.

4. Insert the stem/spacer sub-assembly with the stem gasket into

the side hole of the manual operator body. Rotate the lever of

the stem/spacer sub-assembly to the 12 o'clock position.

5. Install stem retainer on base of manual operator body and

simultaneously engage it into the slot provided on the

stem/spacer sub-assembly.

IMPORT NT: The spacer on the stem/spacer sub-assembly must

be outside of the stem retainer for C/DC construction (Figure 1).

6. Install manual operator bonnet gasket and body with

preassembled parts into valve body. Torque manual operator

body to 175 ± 25 in-lbs [19,8 ± 2,8 Nm].

7. Replace solenoid base gasket and solenoid base sub-assembly.

Torque solenoid base sub-assembly to 175 ± 25 in-lbs

[19,8 ± 2,8 Nm].

8. For further reassembly, refer to Valve Reassembly step 6.

ORDERING INFORM TION

FOR SCO REBUILD KITS

Parts marked with an asterisk (*) in the exploded view are supplied in

Rebuild Kits. When Ordering Rebuild Kits for ASCO valves, order

the Rebuild Kit number stamped on the valve nameplate. If the

number of the kit is not visible, order by indicating the number of kits

required, and the Catalog Number and Serial Number of the valve(s)

for which they are intended.