6 Seven/Relay Workbench Assembly | INS-SWORKBENCH

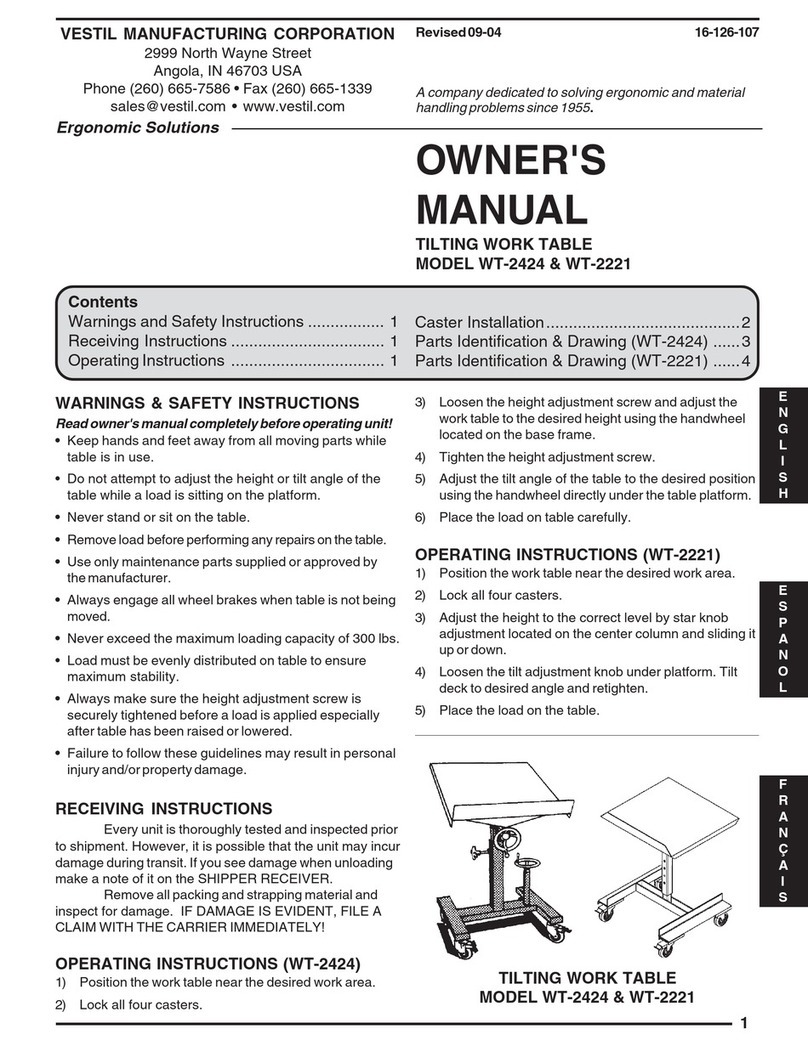

Raceway Modular Power

ARoute Jumpers through raceway channel

BConnect jumpers to the receptacle blocks.

The connectors are keyed for the 4-circuit, 8-wire

system. Tampering with, or clipping, the molded

pins will result in short circuit and void the Watson

warranty.

Extended Connector Kit

(Optional)

AConnect the 15” jumper and coupler

to the standard length jumper.

BConnect the jumper to the

receptacle blocks then secure and

clamp the block to the bottom of the

extended connector with #10-32x⅜”

screw.

Note — Use the jumper

grid to determine the

correct length to use.

Note — Underside shown

for clarity.

Note — Maximum

segments connected:

12 standard power, 6

heavy power.

Note — Connections are keyed to snap in

one way with a positive click. Do not modify

the jumper or harness block as this creates a

safety hazard and voids the warranty.

Note — Connections are keyed to

snap in one way with a positive click.

Do not modify the jumper or harness

block as this creates a safety hazard

and voids the warranty.

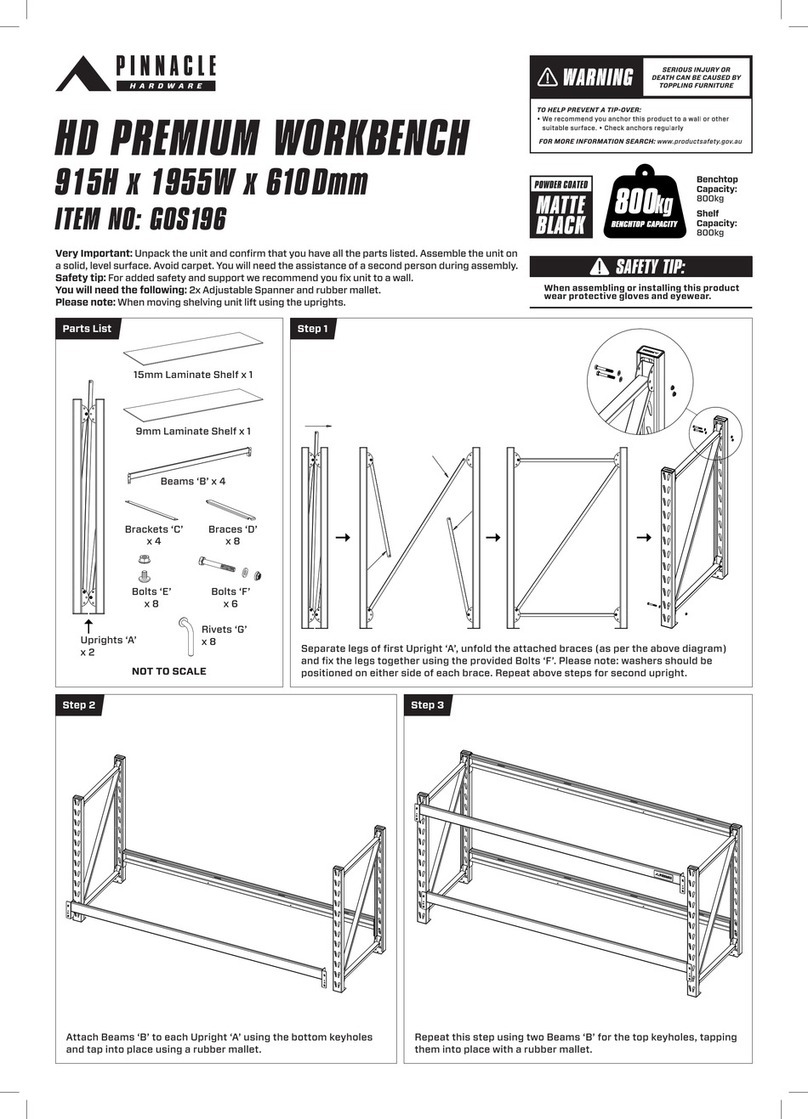

STANDARD

POWER

SEGMENT 2 WIDTH

48 54 60 66 72 78 84

SEGMENT 1 WIDTH

48 37 43 43 49 49 55 55

54 43 43 49 49 55 55 61

60 43 49 49 55 55 61 61

66 49 49 55 55 61 61 67

72 49 55 55 61 61 67 67

78 55 55 61 61 67 67 73

84 55 61 61 67 67 73 73

HEAVY

POWER

SEGMENT 1 WIDTH

48 54 60 66 72 78 84

SEGMENT 1 WIDTH

48 31 37 37 43 43 49 49

54 37 37 43 43 49 49 55

60 37 43 43 49 49 55 55

66 43 43 49 49 55 55 61

72 43 49 49 55 55 61 61

78 49 49 55 55 61 61 67

84 49 55 55 61 61 67 67

5.

6.

B

B

B

A

A

A