ADL300 CiA® 417- Description of functions and parameter list Page 3 of 46

Table of contents

1. Introduction ............................................................................................................................................................... 4

2. REFERENCE STANDARDS....................................................................................................................................... 5

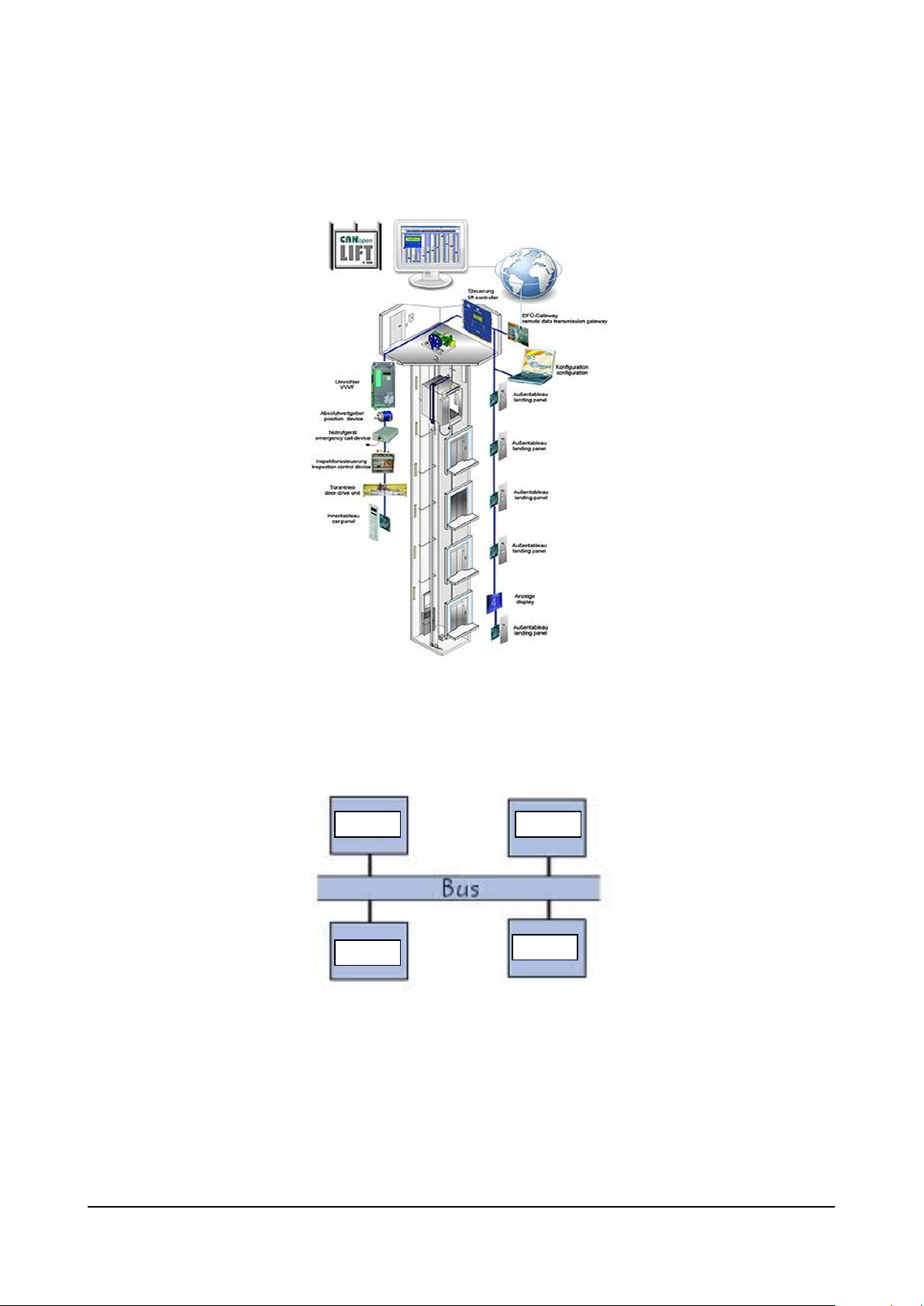

3. A STANDARD COMMUNICATION PROTOCOL ....................................................................................................... 6

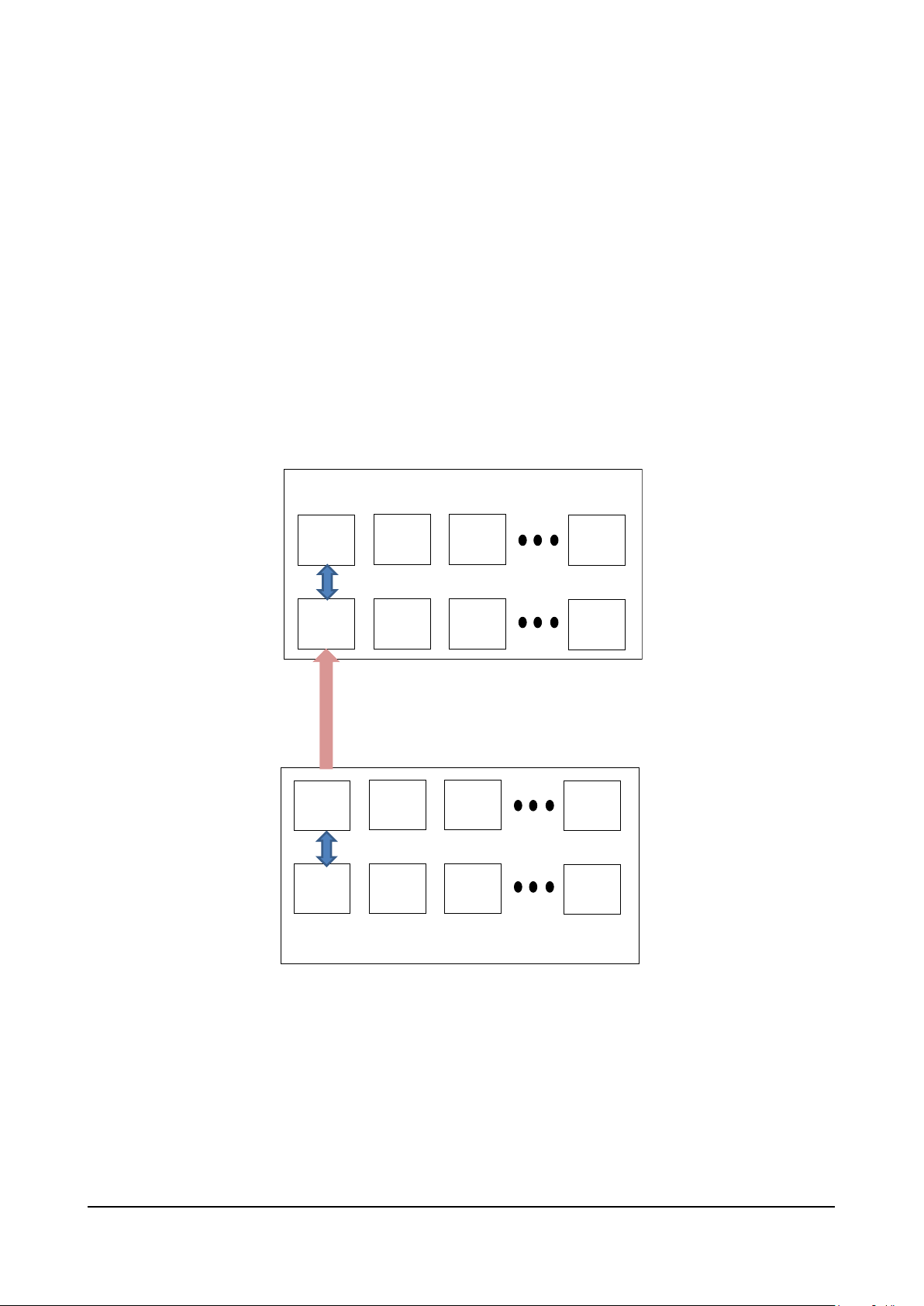

4. SHARING THE DRIVE MENU .................................................................................................................................... 8

5. FUNCTIONAL LOGIC................................................................................................................................................. 9

6. Control mode........................................................................................................................................................... 10

6.1 Speed Control ................................................................................................................................................... 10

6.2 Position Control ................................................................................................................................................. 11

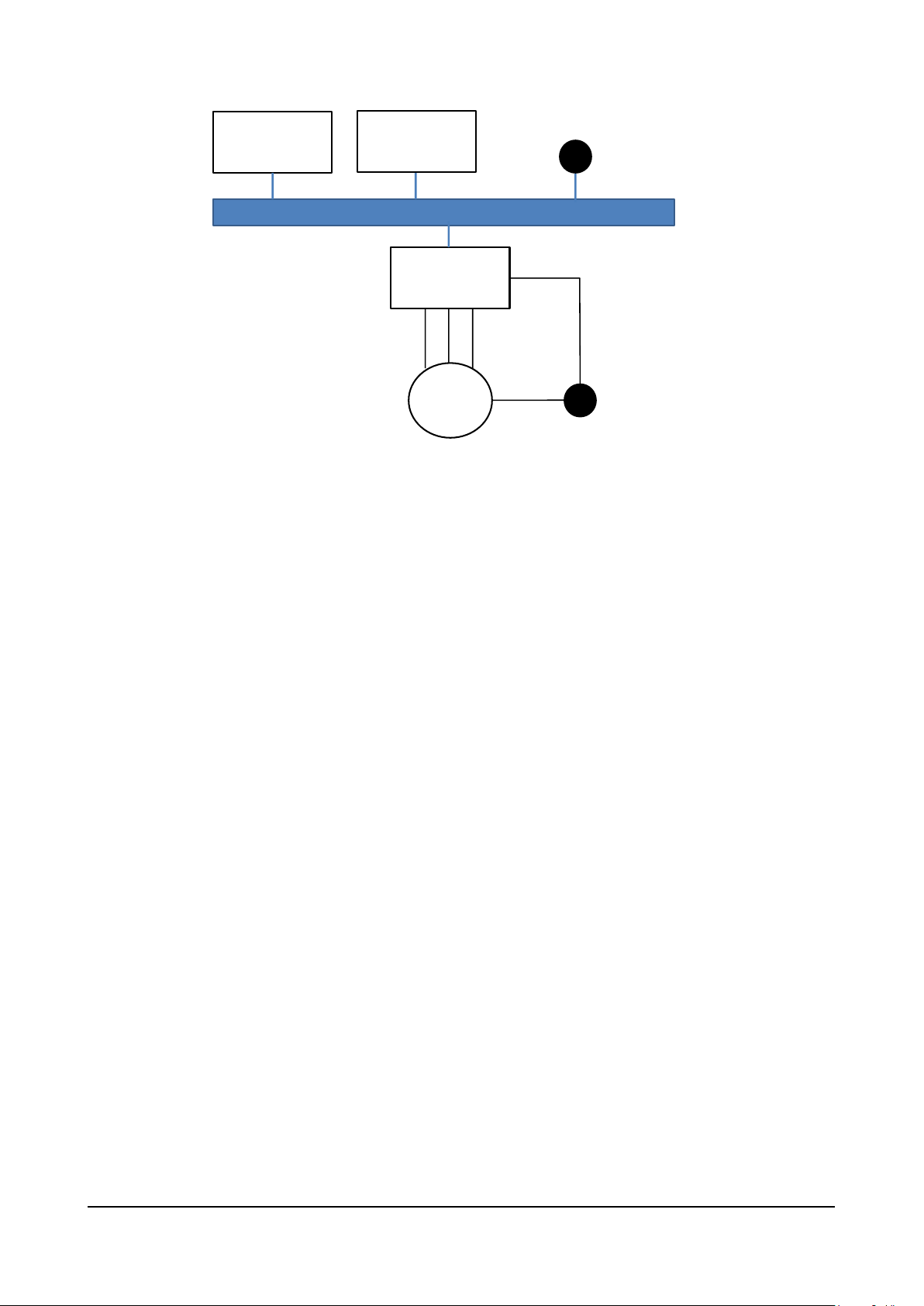

7. SUPPORTED ARCHITECTURES ............................................................................................................................ 12

8. APPLICATION OBJECTS AND PROCESS DATA OBJECTS MANAGED............................................................. 13

8.1 Process Data Object ......................................................................................................................................... 13

8.2 Application Object ............................................................................................................................................. 13

9. STATE MACHINE..................................................................................................................................................... 14

10. DRIVE CONNECTION .............................................................................................................................................. 15

10.1 Interface with Master CAN................................................................................................................................. 15

10.2 Wiring ................................................................................................................................................................ 16

10.3 Bus connection.................................................................................................................................................. 16

10.4 Bit Rates Supported .......................................................................................................................................... 17

10.5 Node IDs ........................................................................................................................................................... 17

11. INSTALLING THE APPLICATION ........................................................................................................................... 18

11.1 General ............................................................................................................................................................. 18

11.2 Requirements.................................................................................................................................................... 18

11.3 Preliminary operations....................................................................................................................................... 18

12. COMMISSIONING FROM ALPHANUMERIC KEYPAD ........................................................................................... 19

13. DESCRIPTION OF PARAMETERS.......................................................................................................................... 22

13.1 Legend .............................................................................................................................................................. 22