4

Wegaconcept

Technical manual

Index

1 Technical characteristics ................................................................ 8

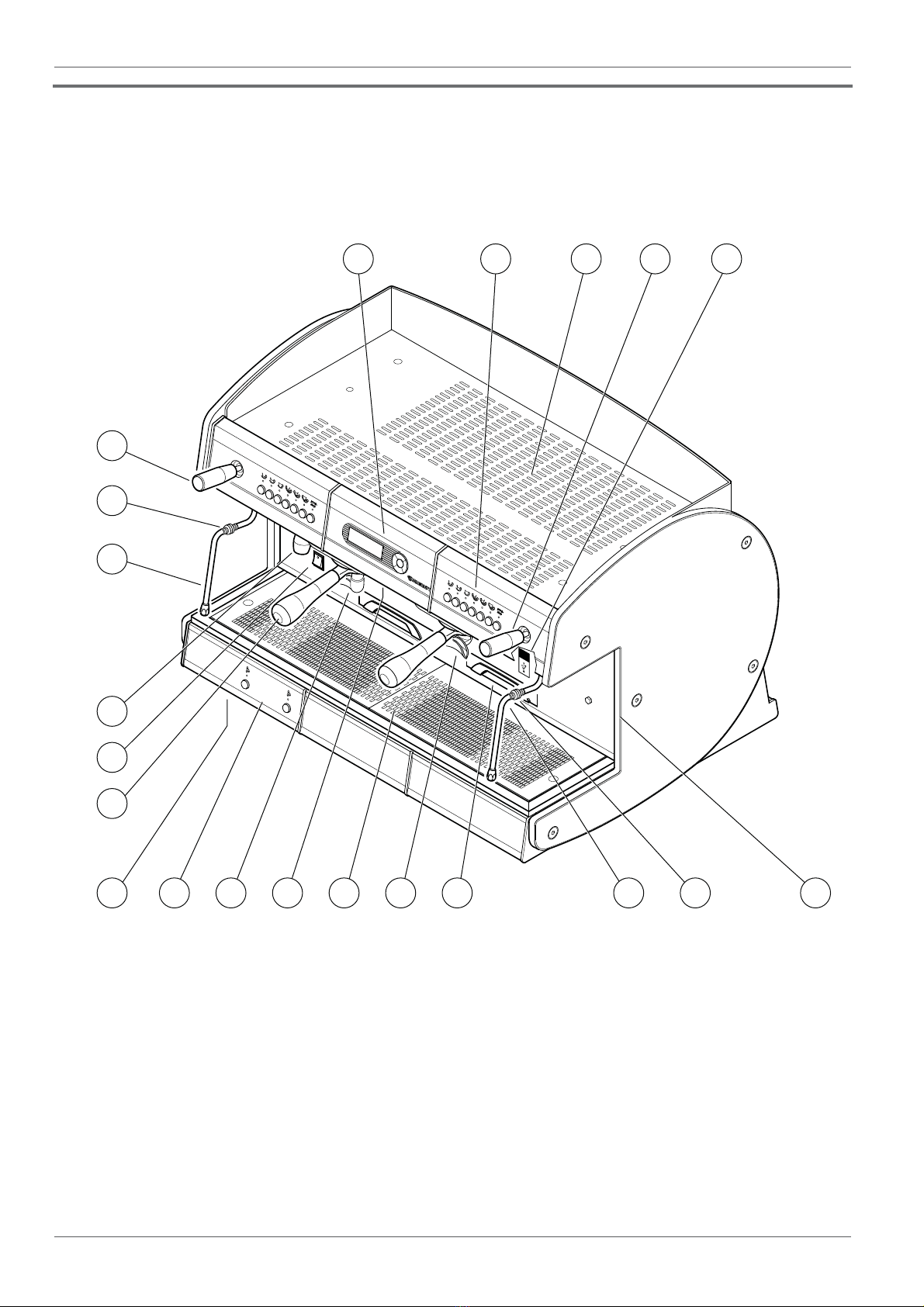

1.1 External components .......................................................... 8

1.2 Internal components........................................................... 9

1.3

Specications............................................................................................10

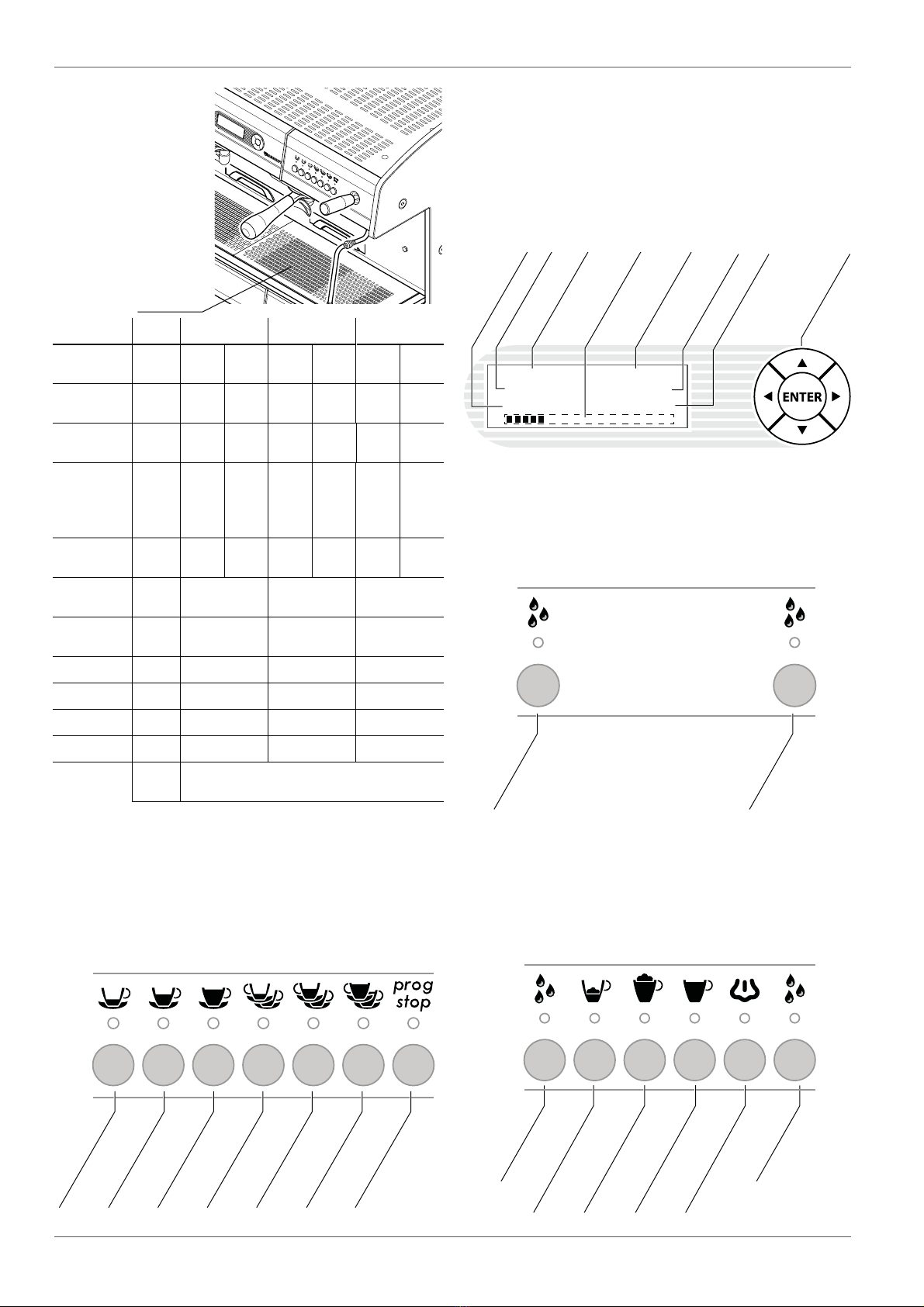

1.4 Push-buttons panels........................................................... 10

2 Preparation.................................................................................... 11

2.1 Unpacking the machine ...................................................... 11

2.2 Equipment preparation ..................................................... 11

3 Machine installation...................................................................... 12

3.1 Positioning ........................................................................ 12

3.2 Hydraulic connection .......................................................... 13

3.3 Wiring................................................................................. 14

3.4 Turning on the machine...................................................... 14

3.5 External motor pump adjustment....................................... 15

3.6 Machine tune-up ................................................................ 15

4 Boilers............................................................................................ 16

4.1 Coee boiler........................................................................ 16

4.2 Services boiler..................................................................... 16

5 Dispensing assembly ..................................................................... 16

6 Automatic Water Entry.................................................................. 17

7 Volumetric dosing.......................................................................... 17

8 Pressure switch.............................................................................. 17

9 Anti-ooding device...................................................................... 17

10 Pumping system............................................................................ 18

11 Valve group.................................................................................... 18

11.1 Pressure limitation safety valve........................................... 18

11.2 Expansion valve- non-return valve...................................... 18

12 Electric control unit........................................................................ 18

13 Thermostat.................................................................................... 18

14 Cup heating device ........................................................................ 19

15 Softeners ....................................................................................... 19

15.1 Regeneration of the softener .............................................. 19

15.2 Regeneration notication and counter reset ....................... 20

16 Dispensing compartment light and illuminated sides.................... 20

17 Preparation of beverages............................................................... 21

17.1 Programming the coee doses............................................ 21

17.2 Coee preparation .............................................................. 21

17.3 Programming the hot water doses...................................... 21

17.4 Hot water delivery............................................................... 22

17.5 Regulation of the hot water temperature ........................... 22

17.6 Steam delivery.................................................................... 22

18 Cappuccino maker ......................................................................... 23

18.1 Installation.......................................................................... 23

18.2 Cleaning.............................................................................. 24

18.3 Cappuccino.......................................................................... 24

18.4 Warm milk .......................................................................... 24

19 Autosteamer.................................................................................. 24

19.1 Description.......................................................................... 24

19.2 Automatic heating and foaming ......................................... 25

19.3 Automatic heating .............................................................. 25

19.4 Manual heating and foaming.............................................. 25

19.5 Automatic autosteamer nozzle cleaning. ............................ 25

19.6 Autosteamer system operation ........................................... 26

20 Energy Saving ............................................................................... 27

20.1 Description.......................................................................... 27

20.2 Energy savings programming.............................................. 27

20.3 Programming of group stand-by......................................... 27

21 Group washing .............................................................................. 27

22 Cleaning ........................................................................................ 28

23 Checks and maintenance............................................................... 29

23.1 Control and maintenance operations .................................. 29

23.2 Scheduled assistance .......................................................... 31

23.3 Grinders wear check............................................................ 32

24 Malfunctions and related solutions................................................ 32

25 Alarms and display indications ...................................................... 35

25.1 Display indications.............................................................. 35

25.2 Alarms................................................................................. 35

26.List of hazards................................................................................ 37

27 USB drive ...................................................................................... 38

27.1 Data saving ......................................................................... 38

27.2 Restoring data..................................................................... 38

27.3 Software Update................................................................. 38

28 Programming ................................................................................ 39

28.1 Access to the programming................................................ 39

28.2 Browser key......................................................................... 39

28.3 Programming menu............................................................ 40

28.4 Boiler pressure adjustment. ................................................ 40

28.5 Adjustment of coee water temperature. ........................... 41

28.6 Adjustment of the groups temperature............................... 41

28.7 Adjusting the cup heater temperature ............................... 42

28.8 Programming of Energy Saving time and groups stand-by. 42

28.9 Conguration of groups proper use..................................... 43

28.10 Standby mode..................................................................... 44

28.11 Autosteamer option............................................................ 45

28.12 Softener regeneration......................................................... 46

28.13 Display of the counters........................................................ 46

28.14 Setting the date .................................................................. 47

28.15 Setting the working days .................................................... 48

28.16 Setting the language .......................................................... 48

28.17 Delivery check..................................................................... 49

28.18 Programming group washing ............................................. 50

28.19 Setting the number of active groups................................... 51

28.20 Loading the default data..................................................... 51