Contents

1324440000/00/01.13 3

Contents

Preface................................................................................................................................2

Revision history ...................................................................................................................2

Contact address...................................................................................................................2

Copyright notice...................................................................................................................2

Contents .............................................................................................................................3

1. Safety Notices .......................................................................................................5

1.1 Proper and intended use.........................................................................................5

1.2 Qualified staff..........................................................................................................5

1.3 Accuracy of the technical documentation................................................................5

1.4 CE label ..................................................................................................................5

1.5 Declaration of Conformity........................................................................................5

1.6 Recycling in accordance with WEEE ......................................................................6

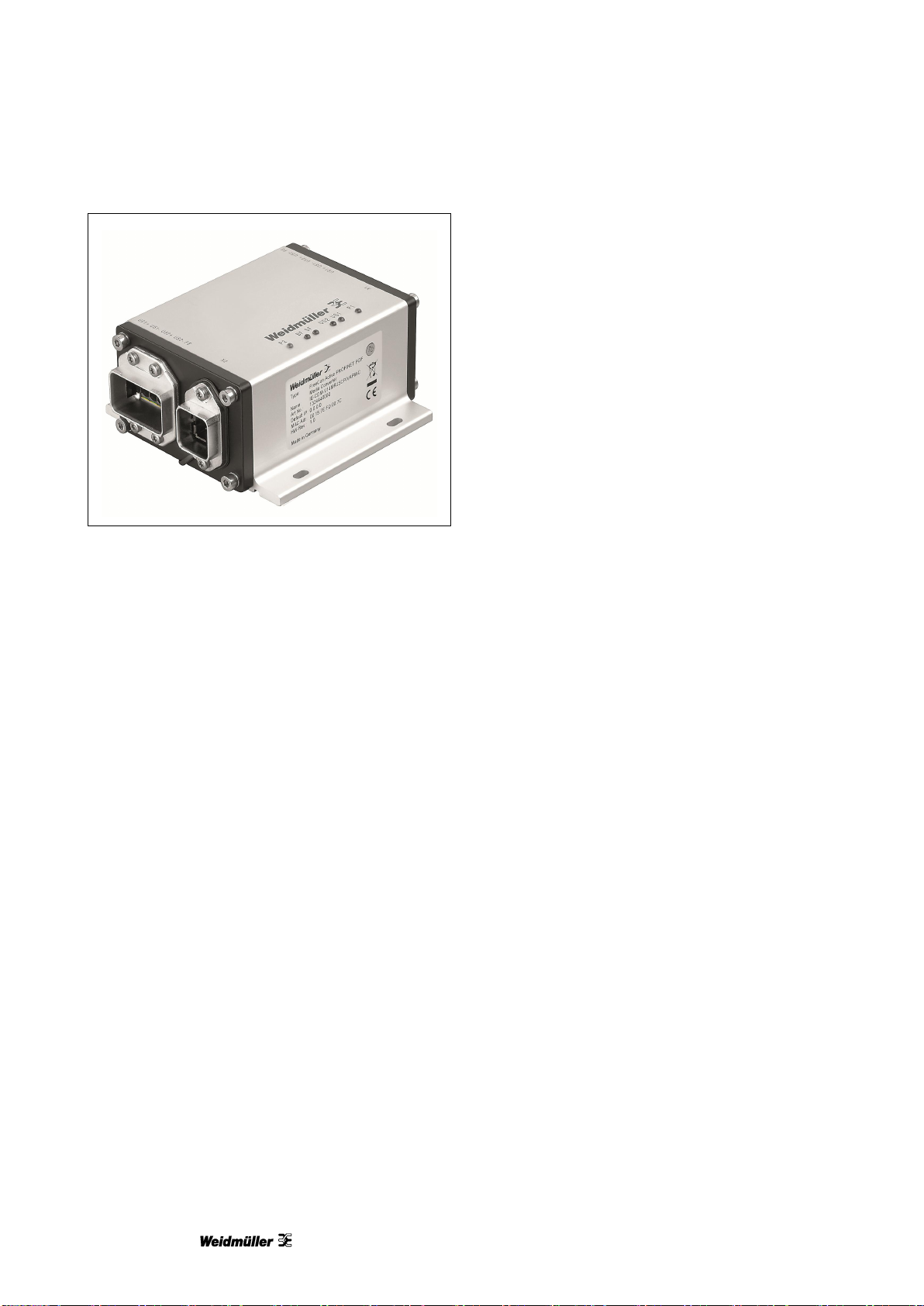

2. The FreeCon Active PROFINET-POF-Media Converter.........................................7

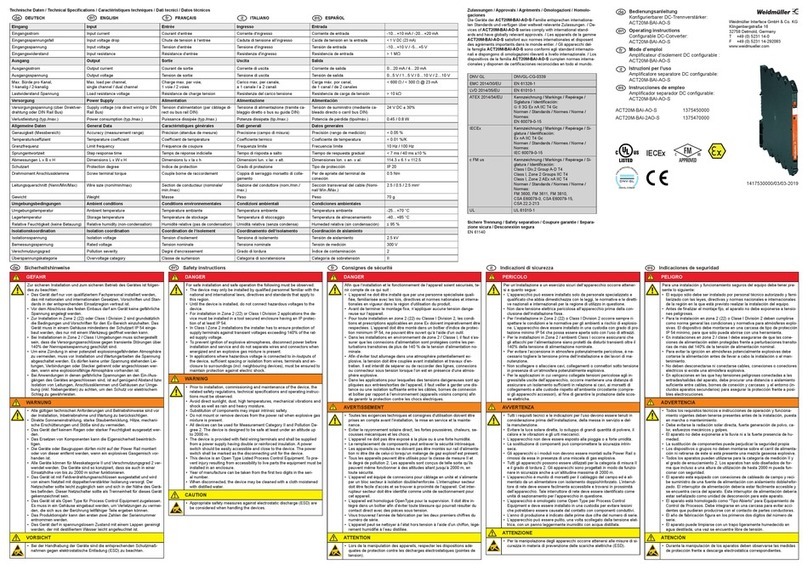

2.1 Electrical Characteristics.........................................................................................7

2.2Internal CPU............................................................................................................7

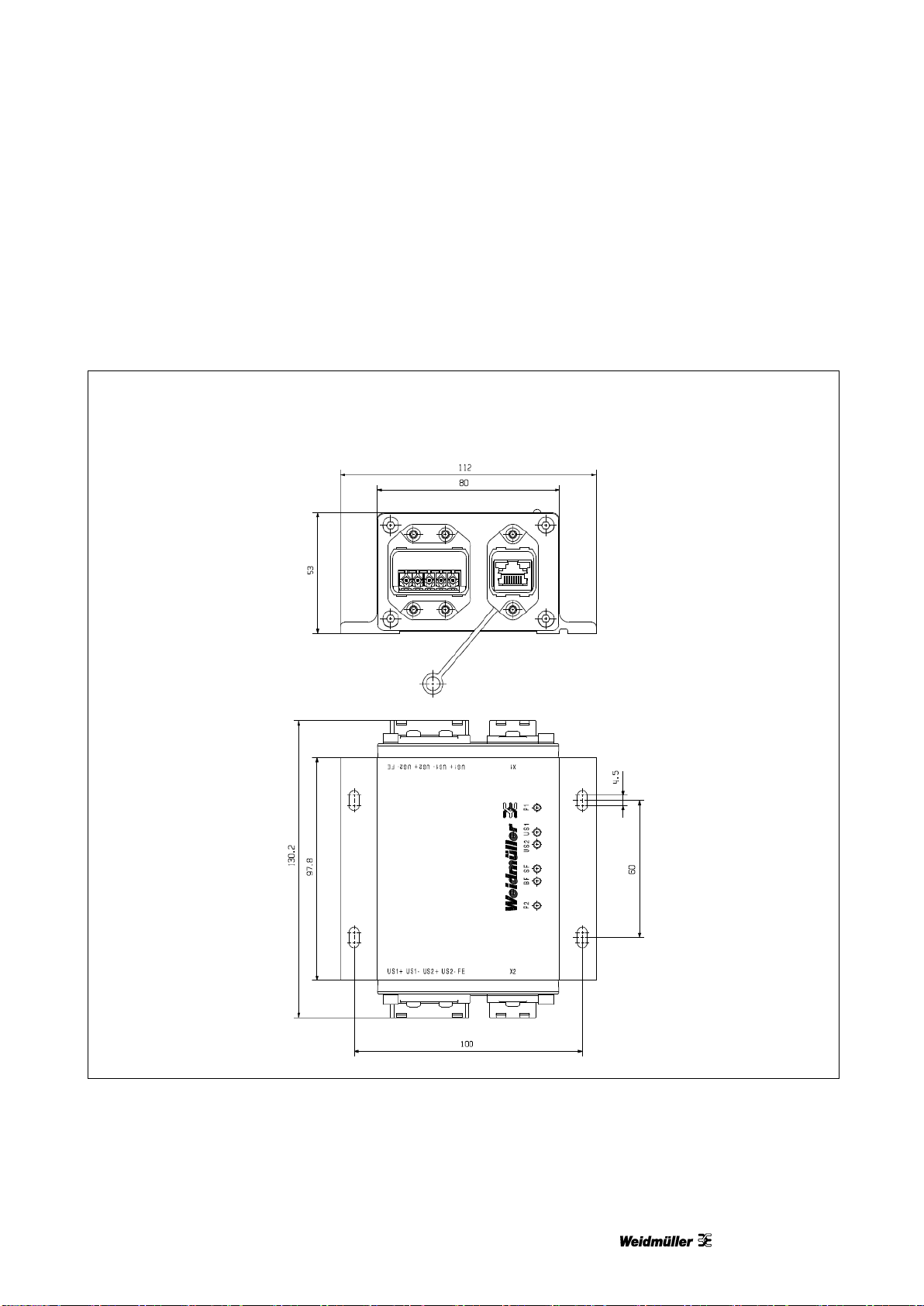

2.3 Mechanical characteristics......................................................................................8

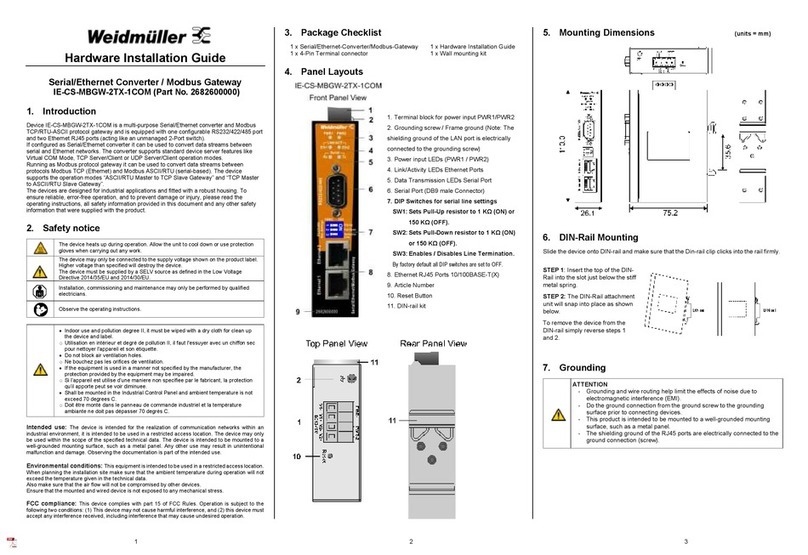

3. Installation and Connectors .................................................................................9

3.1 Mounting .................................................................................................................9

3.2 Power Connection.................................................................................................10

3.3 Data connection....................................................................................................11

3.4 Grounding/earthing ...............................................................................................12

4. Setup and Network Configuration .....................................................................13

4.1 Setup with GSDML-File.........................................................................................13

4.2 Setup with Weidmüller FreeCon CFG...................................................................14

4.3 Using a web browser to access the device ...........................................................15

4.4 SNMP configuration..............................................................................................16

4.5 FTP configuration..................................................................................................16

4.6 Discovery and basic Configuration Protocol (DCP)...............................................16

4.7 Link Layer Discovery Protocol (LLDP) ..................................................................16

5. Firmware Update .................................................................................................17