CIRCUIT

BREAKER

TABLE

1-0-3-VOLTAGE

RATING

OF

COMPONENTS

Nominal Voltage

Rating Range

Components (Volts)

Volts

Closing

Re

lay

115 90-130

and

Magnet 450 360-500

Shunt

Trip

115

80-130

450 360-500

1-0-1-2 Auxiliary Switch

The

interrupting

capacities

of the

auxiliary

switch

contacts

are

listed

in

Table

1-0-4.

TABLE

1-0-4-AUXILIARY

SWITCH

Non-Inductive Inductive

Volts

Circuit

Circuit

115

a-c

75

amps.

15.0

amps.

450

a-c

25

amps.

5.0

amps.

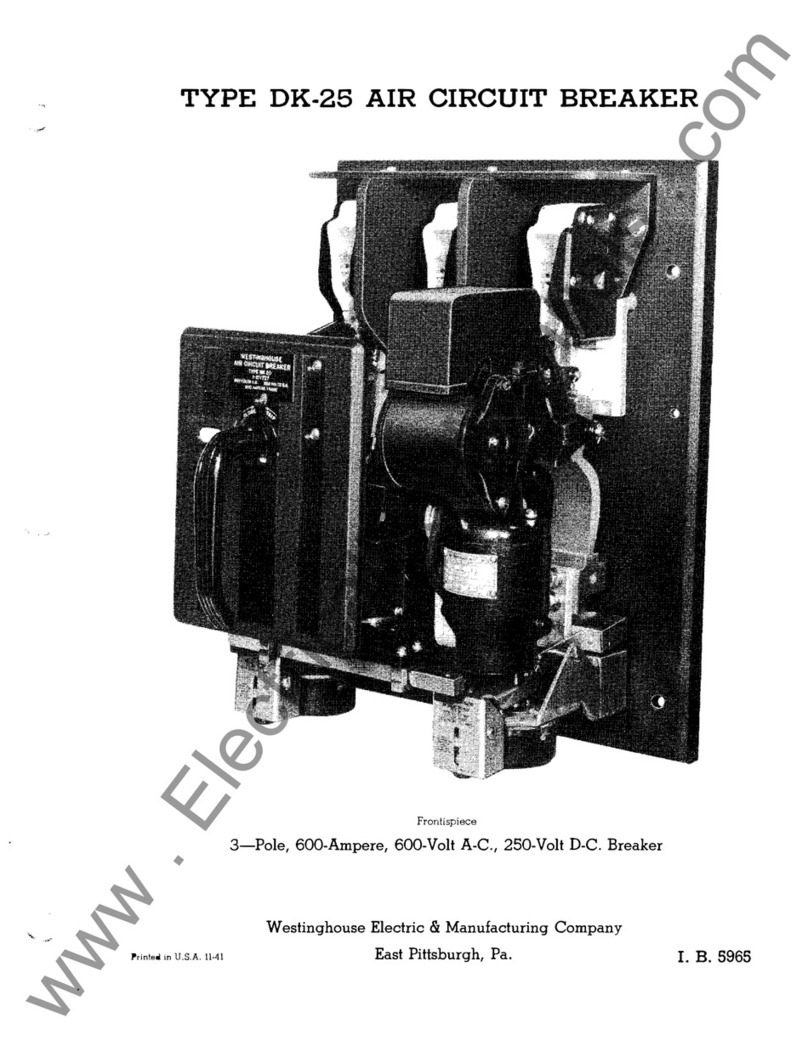

Section l-Introduction

1.1·1

GENERAL

This

technical

manual

describes

a Navy

Type ACB 1600HR (Westinghouse

Type

DBN-

1016)

1600-ampere

frame

size

air

circuit

breaker,

meeting

the

requirements

of

Specifica-

tion

MlL-C-17587

for

Naval

Shipboard

service.

Each

circuit

breaker

is

supplied

as

a

complete,

removable

switchboard

assembly

consisting

of

circuit breaker, separable

disconnects

and

as-

sociated

control wiring, drawout

mechanism

and

assemhly

structual

supports

and

back

plate

in·

cluding stationary main bus connections and

sta-

tionary

terminals

for connection

of

the

necessary

external control wiring.

The

complete,

removable

assembly

consists

of two

major

components;

the

stationary

com-

ponent

that

is

bolted

into the

switchboard

frame,

and

the movable component

which

is

the

oper-

ating

mechanism

of the

circuit

breaker

and

may

be

drawn out for inspection, maintenance

or

isolation

from

the

shipboard

electrical

system.

The

general

arrangement

of

this

equipment

is

shown in

figures

1-1-1

and

1-1-2.

The DBN-1016

air

circuit

breaker

is

a

complete,

removable

assembly

for

installation

within a

switchboard

cubicle.

The

circuit

breaker

is

designed

as

an

as-

sembly

including the drawout

mechanism.

These

assemblies

incorporate

disconnect

features

for

both main current connections and secondary

current connections.

This

mounting allows

easy

'·2

removal

and

installation

of the movable

compo-

nent when maintenance operations

are

required.

The

circuit

breaker

is

closed

electrically

from

a

local

or

remote

control

switch.

It

may

be

tripped

from

the

control

switch

or

may

be

tripped

by

depressing

the

"Push-To-Trip"

button

which

protrudes

through

the

face

plate.

For

maintenance, the

emergency

closing

handle

provides

manual

closing

by

inserting

the

operating

handle,

through

the

face

plate,

into

the

socket

provided

in the

operating

mechanism

and

pulling the

operating

handle down

(approxi-

mately

45

degrees)

until

the

breaker

latches.

The moving

component

consists

of a

rigid

steel

chassis

to

which

are

bolted

various

sub-

assemblies.

Each

sub-assembly

is

a

complete

unit

and

is

readily

interchangeable

between

breakers.

In

addition,

each

sub-assembly

may

be

removed

intact

and

easily

replaced

for

mini-

mum outage

time.

·The

sub-assemblies

requiredin

all

breakers

are

the mechanism, pole units,

arc

chutes, aux-

iliary

switch, secondary disconnects,

anti-shock-

closed-device,

anti-shock-open-device,

closing

relay,

and

closing

magnet.

The

remaining

sub-

assemblies

that

may

be

included

are

overcurrent

trip

devices

and shunt

trip

device.

The

air

circuit

breaker

for

three

phase

a-c

service

is

normally provided with overcurrent

trip

devices

in the two

outer

poles,

otherwise

the

three

poles

are

identical.

(