RECEIVING

,

HANDLING

AN

®

STORING

t

/

W

MT

'

KOmtilunvMMUaa

.

t

'

.

wAilisXliasCOKlA

'

.

i

’

.

l

’

)

-

.

X

*

-

41

'

m

*

*

e

-

X

~

'

•

l

-

*

*

"

«

fr

"

'

"

*

1

>

HSKM

*

/

(

i

,

urwuvIJ

.

I

.

!

.

•

-

«

J

w

;

,

.

„

wrl

1

„

with

slings

under

the

orate

.

II

the

breaker

is

to

be

Jilted

with

slings

,

move

it

while

it

is

still

crated

.

Alter

the

breaker

is

unpacked

,

the

best

way

to

move

it

is

by

rolling

it

on

its

own

wheels

,

;

H

it

is

necessary

to

lift

the

breaker

after

if

is

tmcrated

,

lilt

it

without

the

arc

chutes

or

;

barriers

in

,

place

.

Slings

may

be

placed

under

the

!

breaker

frame

.

or

in

holes

provided

in

the

frame

.

!

Use

a

spreader

to

prevent

th

©

cables

from

distorting

the

blowout

magnets

.

STORING

The

arcing

chambers

are

shipped

in

separate

containers

to

guard

against

damage

from

rough

handling

and

for

better

protection

,

from

dust

and

water

or

liquids

,

containers

until

ready

for

us

©

.

Store

all

components

of

these

breakers

in

a

clean

dry

place

..

During

the

storage

period

,

keep

them

sufficiently

warm

to

prevent

'

moisture

condensation

.

Store

them

in

their

shipping

TABLE

©

IP

APPROXIMATE

*

WEIGHTS

(

1

m

Fm

.

radte

)

•

W

'

l

IRMtflu

>

|

i

f

.

»

i

WH

*

4

>

V

1

N

1

»

NIMto

>

l

*

MWti

»

*

4

%

&

*

«

«

>

*

**

uAuvMlxt

'

.

ViKj

i

,

«

,

*

_

*

>

.

;

*

*

»

MU

»

nnrii

»

)

<

=

-

•

»

J

1

l

\

t

-

/

J

>

.

'

On

<

'

h

;

4

t

/

i

.

i

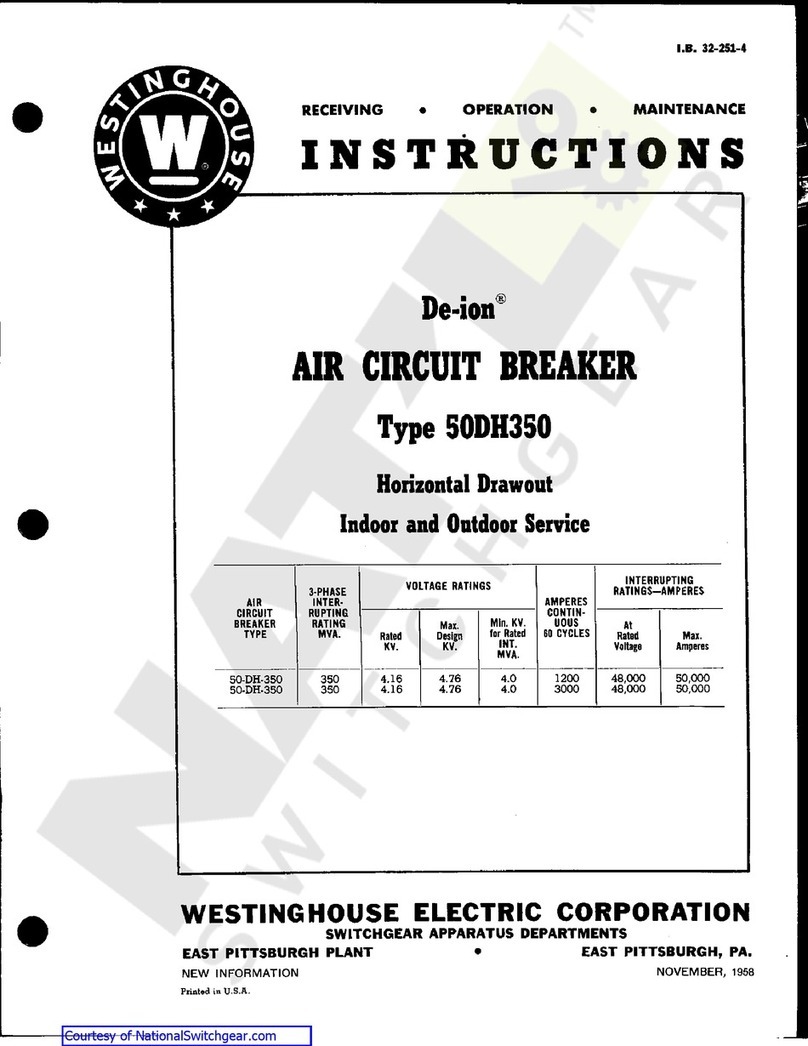

BREAKER

WITHOUT

CHUTE

ft

BARRIER

>

BREAKER

*

SINGIE

m

CHUTE

AMPERE

RATING

BARRIER

ASSEMBLY

COMPLETE

BREAKER

TYPE

80

-

DH

*

150

-

1

)

S

0

-

DH

-

1

S

0

-

D

600

-

1200

2000

676

45

75

1065

1050

45

95

1.260

'

80

-

DH

-

2304

)

50

-

DH

-

250

-

D

1200

875

•

1050

45

75

1085

1280

2000

45

95

1400

75

-

DH

-

250

-

A

75

-

DH

-

500

1200

-

2000

1200

-

2000

•

65

160

1750

2075

1600

105

160

150

-

PH

-

150

-

A

160

«

DH

-

250

-

A

.

150

-

DH

-

250

A

150

-

DH

-

500

-

A

150

-

DH

-

50

Q

-

A

600

-

1200

1200

2000

'

1200

2000

1250

70

'

160

1620

1250

70

160

1620

1770

1928

2075

1400

70

160

1450

105

160

105

1600

160

iMjaattmiwaisiraiwiaitiiiiiafisiBsii

ttvwwnii

Bjouui

.

'

aeww

w

,

i

>

luiMittiMSmvuuiwmtui

^

iausMitfswmJhfctirUMi

^

w

.

UiHtfjiiv

/

.

uiimfcnsiWWiWMMsnaHaiiii

I

*

M

;

«

PH

#

M

«

H

J

;

JMI

IUKI

M

a

*

.

n

sviiiiuiMitm

:

'

*

]

Mummenunai

uu

iMit

*

un

»

tin

iLiflowM

'

iSi

.

'

KiJUiKifeitfxo

i

^

tnui

itursw

*

AIM

*

,

INSTALLATION

With

the

exception

of

the

arcing

chambers

and

barriers

,

these

breakers

are

shipped

completely

{

assembled

and

adjusted

.

No

adjustments

should

be

required

and

none

should

be

made

unless

obviously

needed

.

!

i

When

the

breaker

has

been

removed

from

the

crate

,

remove

braces

which

support

the

blowout

magnet

pole

pieces

during

shipment

,

CmiMmw

Severe

injury

may

be

sustained

if

any

part

of

the

body

is

struck

by

the

con

-

tact

arms

since

they

move

very

rapidly

on

the

opening

stroke

.

Personnel

working

about

the

breaker

should

stay

clear

o

£

the

£

rpaco

in

which

the

contact

arms

move

while

breaker

is

closed

or

is

being

closed

,

.

If

breaker

has

been

closed

by

hand

,

always

remove

hand

closing

lever

before

trippixig

.

The

following

sequence

of

operations

should

be

performed

in

preparing

the

breaker

for

use

:

3

L

Breakers

are

usually

shipped

with

the

con

-

tacts

closed

and

with

a

tie

on

the

trip

lover

to

'

pre

*

grease

.

vent

tripping

.

Alter

the

breaker

is

unpacked

and

the

shipping

lies

and

braces

removed

,

lake

off

the

tie

on

the

trip

lever

and

trip

the

breaker

.

Then

close

the

breaker

carefully

by

hand

,

using

the

removable

hand

closing

lever

.

Make

certain

ilial

all

parts

are

functioning

properly

and

,

that

there

hi

no

binding

or

excessive

friction

.

As

the

contacts

touch

near

the

end

of

the

closing

stroke

,

the

force

necessary

to

close

the

breaker

increases

rapidly

.

2

>

n

With

the

breaker

hi

the

closed

,

position

,

check

the

contacts

to

make

certain

that

the

adjust

-

ments

have

not

been

disturbed

.

Iter

proper

settings

,

refer

to

the

section

of

Fig

.

6

which

matches

the

contact

,

design

of

the

breaker

being

'

installed

,

adjustments

are

required

,

they

may

be

made

as

described

on

page

9

.

,

K

A

light

film

of

grease

hi

applied

,

to

both

the

arcing

and

main

contacts

before

the

breaker

is

operated

at

the

factory

.

This

film

is

normally

removed

before

shipment

.

Before

the

breaker

is

placed

in

service

,

inspect

all

contacts

fence

.

that

they

are

free

oi

oil

or

l

Courtesy of NationalSwitchgear.com