5

13G264Westward Operating Instructions and Parts Manual

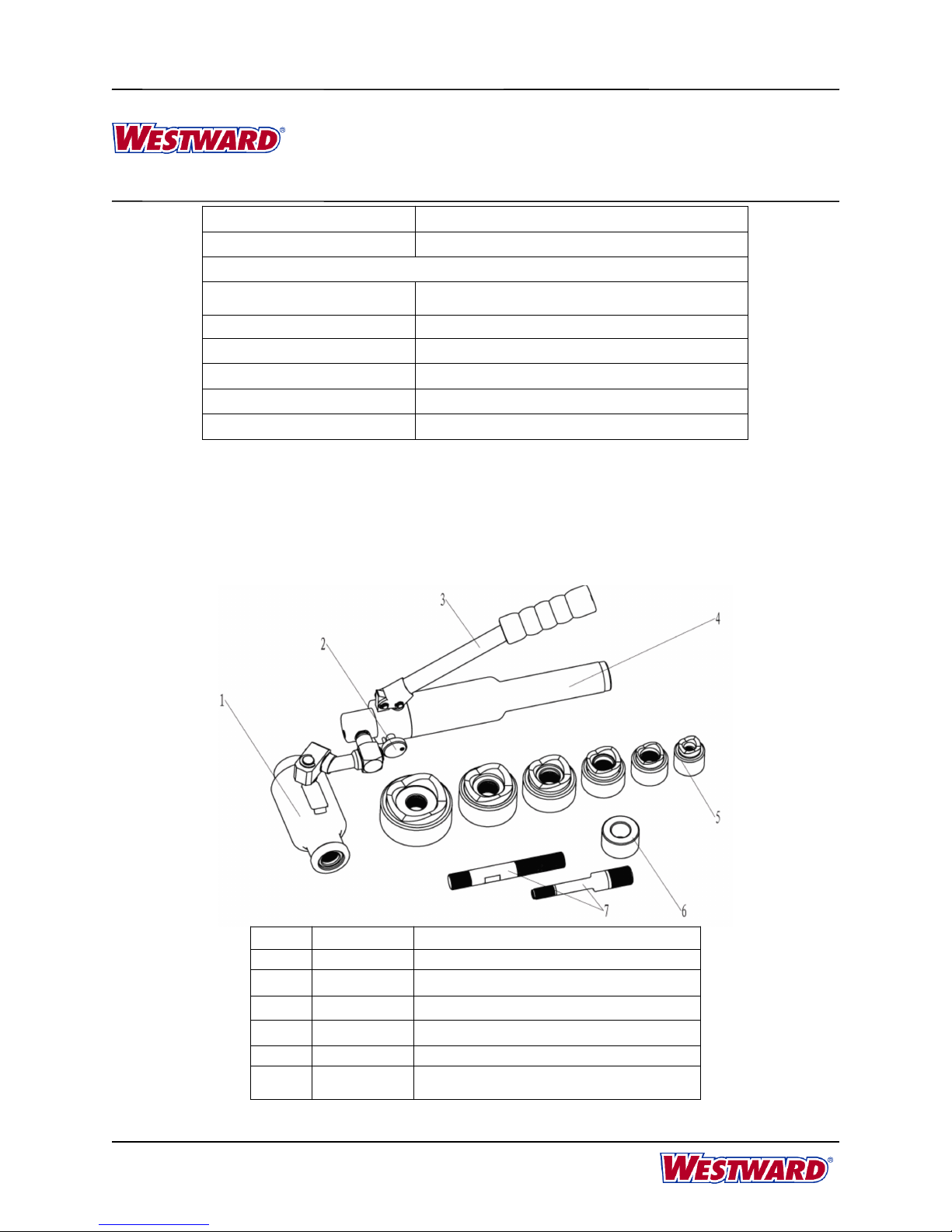

HYDRAULIC PUNCH SET, KNOCKOUT W6 PUNCH, 2

STUDS, 1 SPACER, 1 SEALING KIT

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE AND

AND

AND

AND SERVICING

SERVICING

SERVICING

SERVICING

Damaged equipment may cause serious personal injury. Do not use damaged equipment. If

abnormal noise or vibration occurs, have the problem corrected before further using.

1. Before each using, inspect the general condition of the tool. Check for loose screws, misalignment or binding of

moving parts, cracked or broken parts, or any other condition that may affect its safe operation.

2. After using, clean external surfaces of the tool with clean, moist, smear the rust preventing oil on the metal

surface of the tool and the dies to avoid rusty. Store the tool in the dry environment.

3. Service to the tool should only be done by a qualified Service Technician.

4. After a long time using, the sealing kits will be damaged, if there is leakage please contact with the manufacturer

and/or the distributor to change the sealing kits.

Adding

Adding

Adding

Adding Hydraulic

Hydraulic

Hydraulic

Hydraulic Oil

Oil

Oil

Oila. Place the driver in a vise in a vertical position with the handles up. Unscrew the reservoir handle and remove the

bladder plug. Open the turn screw to assure the ram is fully extended.

b. Fill the rubber bladder to the point of overflow with hydraulic oil.

c. Purge air from the system: Pump the lever handle several times to remove air from the pumping chamber. Close

the turn screw until the ram completes its full travel. Repeat as necessary. Note: Open the turn screw slowly so

the ram extends slowly. Rapid return of oil and air may cause the oil to overflow the rubber bladder.

If this procedure fails to remove air, remove the bladder plug and open the turn screw. Place thumb over the plug

hole in the bladder and squeeze the bladder while pumping the lever handle several times. Close the turn screw

and pump the lever handle until the ram completes its full travel. Repeat as necessary.

d. Fill the rubber bladder to the point of overflow and replace the bladder plug. Wipe the bladder clean of excess oil

and reassemble the reservoir handle.

Oil

Oil

Oil

Oil Leaks

Leaks

Leaks

Leakse. Check for external oil leaks

f. Check that the turn screw and stem are closed tightly and seating properly.

g. Remove the reservoir handle and check for oil leaks around the rubber bladder and bladder plug.

Ram

Ram

Ram

Ram Section

Section

Section

Section Will

Will

Will

Will Not

Not

Not

Not Rotate

Rotate

Rotate

Rotateh. Loosen and readjust the set screw.

i. Hold the punch driver with the ram section down.

j. Apply a small amount of penetrating oil to the cylinder at the attachment point, and then work the ram section

back and forth.

The dust or air inside the tool will damage the sealing kit so caused the tool lose function. Make sure the

oil is clear and no dust entering into oil when changing oil. Wait for a while and exhaust the oil

completely out of the oil tube before inserting the oil plug.

Please wear the rubber gloves to avoid skin touching the oil directly, if touches it in careless, please

wash the skin by soap water in timely. In order to protect the environment please drain the waste oil to the treatment

center where was approved by government.