GettinG Started

Safety /

SpecificationS

aSSembly /

inStallation

operationtroubleShootinG

maintenance /

repair

OPERATING INSTRUCTIONS

4

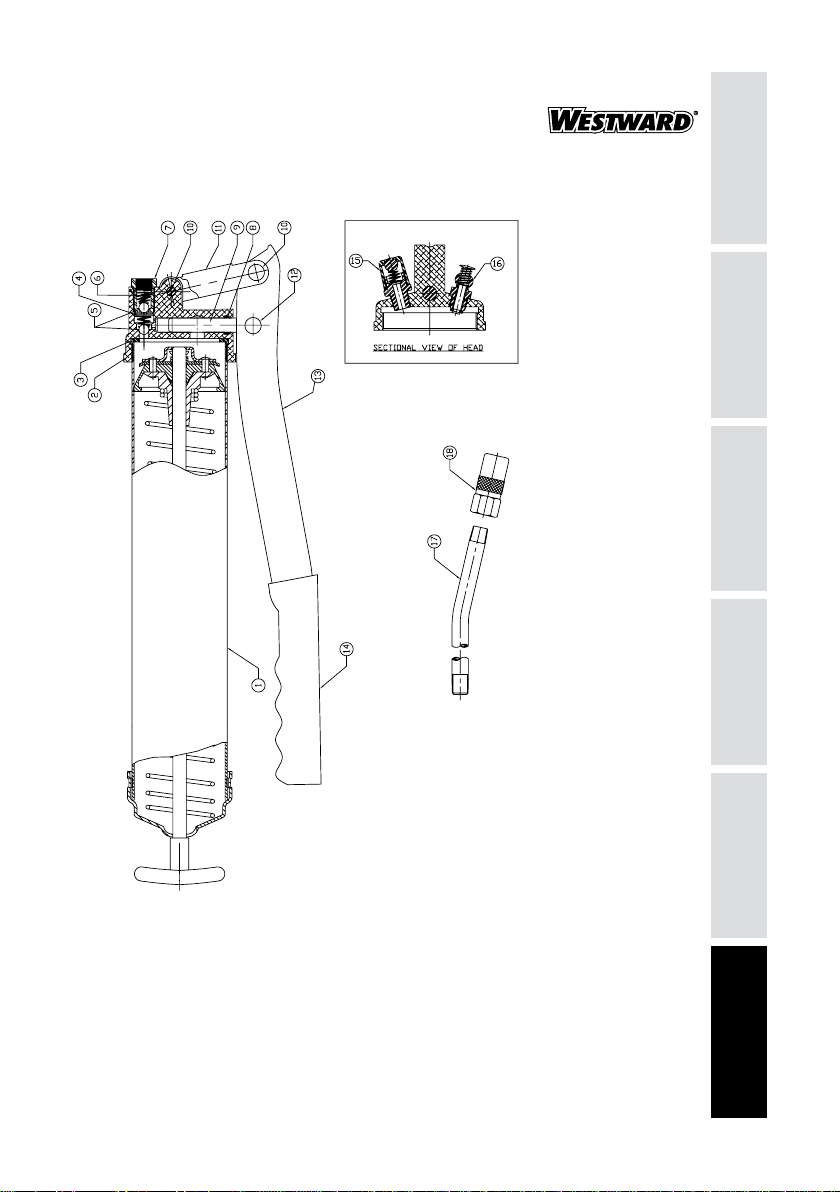

Cartridge Loading Bulk Loading Filler Pump

Pull the plunger rod

handle all the way back

and lock it using the notch

in the end cap.

Pull the plunger rod

handle all the way back

and lock it using the notch

in the end cap.

Wipe the grease gun’s

bulk loader valve free

of grease and possible

debris.

Activate the transfer pump

until a small amount

of grease comes out.

This step will minimize

transferring of any trapped

air from the ller pump to

grease gun.

Remove the gun head

by rotating it in counter-

clockwise direction.

Remove the gun head

by rotating it in counter-

clockwise direction.

Connect the bulk loader

valve tightly to the loader

adapter on the ller pump

line.

Remove the plastic cap

from the cartridge and

insert the open end of the

cartridge into the grease

gun barrel until the rim

of the pull-tab end meets

the rim of the barrel. Now

remove the pull-tab seal.

Screw back the grease

gun head tightly onto the

barrel.

Fill the barrel with grease

using a scoop. When the

barrel is completely lled

with grease, shake the

grease gun barrel to allow

the grease to settle down.

Then screw back the

grease gun head tightly

onto the barrel.

Start operating the transfer

pump, keeping your hand

on the grease gun, lightly

pushing it down onto the

ller pump.

Once the gun barrel is

lled, pumping would get

very hard. Stop now &

disconnect the bulk loader

valve from the ller pump

line. Wipe the bulk loader

valve again.

prime the grease gun

1. Release and push the plunger rod 2-3 times inwards and simultaneous press

the manual air release valve present at the top of the grease gun head allowing

trapped air to escape.

2. Operate the gun, if the grease comes out smoothly from the coupler, then the

grease gun is primed. If not then repeat step 1-2.