7

USB connection; four stereo analog and four AES/EBU outputs to connect

to headphone amps, monitor speakers, or local recorders; and two RJ45

Logic jacks (twelve WNIP-compatible LIO).

Razor Blades, M4IP-USB Blades, WNIP peripherals, and PCs using WNIP

audio drivers are all networked with the EMX using one CAT5e or CAT6

cable of up to 330 feet (100 meters). Three of these devices can plug into

open ports on the Mix Engine’s switch. Connecting additional devices

requires adding one or more AoIP switches to create a PRE-IP network.

Port 1 of the Mix Engine’s switch is then connected to the AoIP switch.

PRE-IP Network

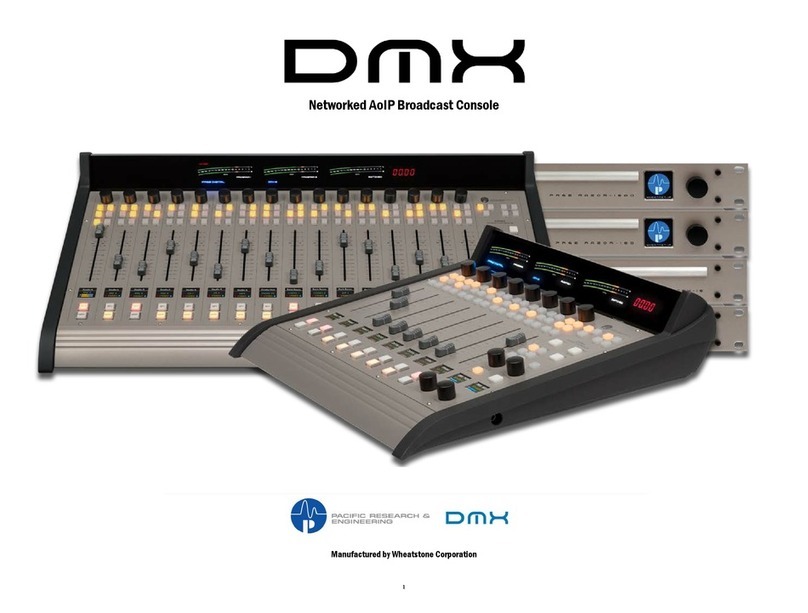

EMX consoles use a subset of the WheatNet AoIP (WNIP) networking

protocol. This allows multiple DMX and EMX consoles, Razor I/O

Interfaces, M4IP-USB Blades, and other WNIP-compatible devices (like PCs

and audio servers) to share their resources in an AoIP network. Appendix

A details how to move beyond a single EMX console to network multiple

PRE-IP and WNIP devices together to form a facility-wide AoIP network.

The PR&E System Configuration Tool, supplied with the EMX console, is

used to add new EMX or DMX consoles and Razor I/O Interfaces to your

EMX console. This app changes the new device’s default settings to unique

settings so the new device can be networked with your existing PRE-IP

devices for “plug-and-play” system expansion.

EMX consoles support the WNIP ACI (Automation Control Interface)

which allows remote EMX Surface control and/or monitoring by external

3rd party devices, tablets, and software apps. Note that ACI is not

supported by DMX Surfaces.

Both DMX and EMX consoles do support WNIP SLIO (Software Logic

I/O) so automation systems, talent panels, script engines, and GPIO ports

can send/receive logic commands over Ethernet. To interface external

devices that do not support WNIP SLIO, there are six hardware LIO (Logic

Inputs/Outputs) ports on each Mix Engine and Razor I/O Interface (and

twelve on the M4IP-USB Blade) to connect “old school” GPIO devices.

EMX Surface

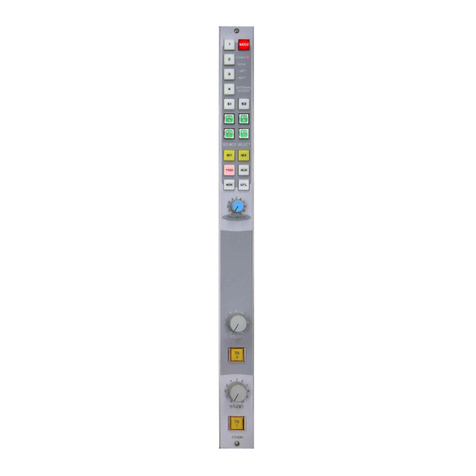

The EMX Surface has two types of operator control panels: multiple

Quad Fader panels and one Monitor Control panel.

Each Quad Fader panel has four fader channels (one channel strip is

shown in Figure 1-4), each with a 100 mm conductive-plastic fader for bus

level control plus thirteen LED illuminated channel buttons for: Channel

Off; Channel On; Cue on/off; momentary Talkback (TB); Telco Auto FB

(Fold Back) on/off; five bus assignment buttons (Off Line, PGM 1, PGM 2,

PGM 3, and PGM 4); and three user-assigned Soft buttons.

A large-knob rotary encoder, at the

top of each channel strip, allows the

board operator to select the audio

source for that fader channel. A

channel display, located just below

each channel fader, shows the audio

source name currently connected to

that fader channel, along with other

source and channel status

information.

When the encoder is rotated—while

the channel is off, the channel display

switches to list the alternate sources

for that channel, with one name being

highlighted. Pressing once or “clicking”

the rotary encoder “takes” the

highlighted source, connecting it to

that fader channel.

The fader channel audio can be

assigned to any combination of the

Program and Off Line buses using the

PGM 1 – PGM 4 and Off Line bus

assignment buttons. The buttons light

up when assigned. The Off Line bus is

exclusively used with callers and

remotes to create s unique IFB

(Interruptible Fold Back) or mix-minus

signal for each hybrid and codec.

The Monitor Control panel mounts

near the right end of the Surface. It

has three control columns: the left

column has the monitor controls for

the Control Room (CR/HDPN); the

middle column has the Studio monitor controls; and the right column

(Meter) has controls to select the switched meter source; to control the

meter bridge timer; and to save and/or take console events.

A PRE-IP network is not interoperable with a WNIP

network. The EMX and DMX consoles, and Razor I/O

Interfaces, do not have the Intelligent Networking

capabilities built into every WNIP Blade. However, audio

resources can be streamed between a PRE-IP network

and a WNIP network when the WNIP system’s Navigator

software has been licensed for “cross-networking.” For

more information, contact Wheatstone technical

support—prior to networking a WNIP and PRE-IP system

together, to ensure the two systems are running code

that supports cross-network audio streaming.

Figure 1-4 EMX Surface Controls