Suspended/Surface Pod Optic, Prism/Diff & Infills for Straight and Corner

sections

1. Unpack and check the contents for any damage.

2. Remove diffuser/pods/Infill and place in a dust free area. The infill will require

the earth tag and safety hooks unclipping.

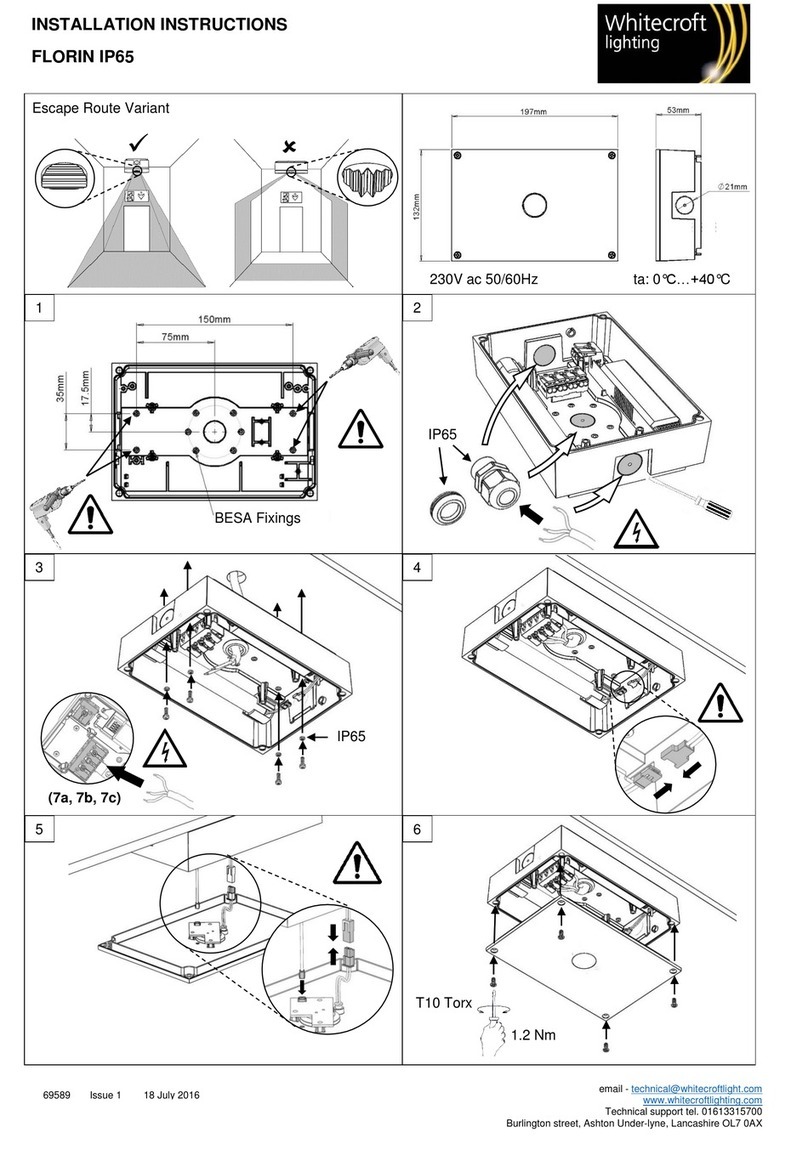

3. Suspension Mounting Option part code (AOSUSKIT)

a. Fix ceiling rose centres as below. Feeding the suspension cable through the

cap. Two suspension points per straight length and one for a corner fitting.

b. Assemble clutch to suspension bracket with M4 nut.

Ensure clutch wire exit hole is at 45° so wire feeds down channel.

c. Slide bracket into hook feature on extrusion and

secure with screw. Making sure orientation is correct so the screw

lines up with hole. Note: Position can be moved but won’t be fixed.

d. Lift the fitting and feed the cable through the clutch.

e. Any access cable can be located in channel of extrusion.

f. Use spirit level when adjusting the clutch.

g. If continuous run repeat a-f.

h. For Straight continuous products the

alignment bracket and cam will be

needed. Part code (AOCMOKIT).

Supplied separately.

Make sure the pip on the cam bracket

is aligned with the dimple in the round

cut out as shown. Slide the bracket half

into the body on the hook side with the ‘U’ shape

positioned as shown.

i. For Corner fittings allow to hang from one suspension. Use the alignment

bracket and screws supplied with the continuous mounting kit –AOCMOKT.

Discard the CAM. With the gear tray of the adjacent fittings dropped (step

4g), slide the alignment bracket into one of the adjacent fittings and secure

using two of the screws supplied. Slide the other alignment bracket into the

other adjacent fitting but do not secure with screws. See 4e for image.

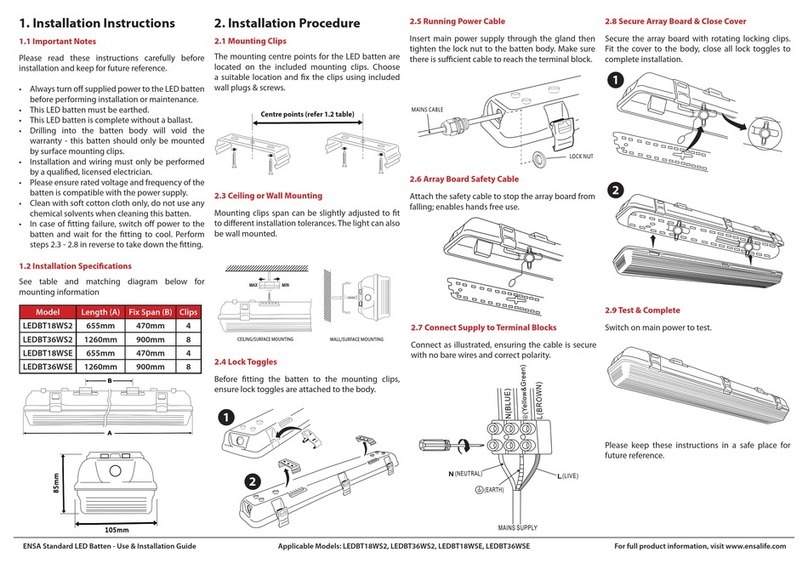

4. Surface Mounting Option part code AOSMOKIT (supplied as a separate item)

a. Fix surface bracket to ceiling using below guide (screws not supplied), two

brackets required for straight fittings and one for a corner fitting.

Orientation is important so follow images. All brackets face same way.

b. For all fittings slide hook bracket onto the extrusion and align with the oval

hole as shown below. Use the M4x6mm screw and serrated washer to

secure in place. Make sure that the ends of the hook are in line with the

edge of the oval hole. This is important.

c. The hook is designed to slide into the

slot feature on the ceiling bracket.

d. Lift the fittings up onto the ceiling

brackets and slide the hook into

the slot until it stops. For continuous/

corner sections as this happens the

open end of the fitting will slide onto the

alignment bracket from steps 4 e/f.

For corner fitting slide the unsecured

alignment bracket across to bridge the

fittings. Note the fitting is still

moveable at this point and care

should be taken until the final fix is

complete.

e. For Straight continuous products the

alignment bracket and cam will be

needed. Part code AOCMOKIT.

(supplied separately).

i.Make sure the pip on the cam bracket

Is aligned with the dimple in the round

cut out as shown.

ii. Slide the bracket half into the body

on the hook side with the ‘U’ shape

positioned as shown.