18

Silk

Building a SIlk SL from a frame to a

complete bike is straightforward,

using standard practices. Be sure

to use assembly lube on a carbon

seatpost. The integrated headsets

use more preload than you might be

used to. If you hear any creaking in

the head tube area after your first

ride, simply increase the headset top

cap tension slightly, until the creak

goes away.

Try angling your brake levers in

slightly for a comfortable and

aero position on the hoods. Wear

glasses that do not intrude on your

field of vision. This is more comfort-

able for your neck and faster too

as you can hold your head lower

and still see up the road. On your

first few rides bring an Allen wrench

set with you and experiment with

the angles of the seat, bars, brake

levers etc. There is a lot to gain from

making yourself comfortable on the

bike and small changes can have a

large effect.

After you’ve got your new bike

dialed, try this technique on your next

group ride:

1. Shoot off the front using the

slingshot draft off the group, soft

pedal as they catch you with a big

reaction. Do it again in a minute or

so, then again.

2. About the 3rd or 4th time you do

this, they will give you some slack

and not chase you down right

away.

3. Gradually apply some power until

you get 150–200+ meters and

then ramp up to full pace. They will

all look at each other eventually

and wait for someone to do it and

it’s often a standoff since nobody

wants to spend that much energy.

At some point a few cross–eyed

guys may show up exhausted from

the battle that happens followed

by the bridge up.

4. Hakkalügi for added emphasis.

General Frame Information

Care for Carbon

The carbon fiber monocoque frame

is extremely strong, and should

provide years of trouble–free use,

provided you care for it properly

and don’t overly huck every 50 foot

gap you see.

Keep your bike clean and inspect

it often. Although each and every

bike gets tested at the factory for

strength, it never hurts to look at the

areas where the tubes join, where

the shocks and dropouts mount and

any other areas that may receive

stress during usage. Check for

loose bearings, headsets, shocks

and forks and such. Visually inspect

the bike before each ride and also

during each cleaning.

Carbon Assembly Compound

This stuff is grease, but with a

bunch of tiny plastic beads added.

This increases friction between

components, great for holding your

carbon seat post or handlebars in

place without excessive clamping

19

Bike Set-Up Tips and Tricks

force. While grease won’t hurt any

of our seat tubes, carbon assembly

paste works even better.

Do not use the carbon assembly

compound when installing the

headset, bottom bracket, shock,

water bottle cage, or anything that

has bearings.

Paint

There is a protective clear coat ap-

plied over the final carbon weave on

all of our gloss clear or matte clear

frames. You can repair small chips

and scratches with clear nail polish

(not supplied.) Colored frames are

painted with a high quality polyure-

thane enamel.

You should have received a small bot-

tle of touch–up paint with your colored

frame. If it’s used up or lost, you can

call and order one from us. Both of

these finishes can wear through with

repeated rubbing of cables or chain

slap. Using the set of adhesive vinyl

protectors provided to guard against

cable rub and chain slap can help

limit wear and tear on your frame.

We try to make our frame finishes

as durable as possible, but it is

impossible to test in all conditions

and against all chemicals.

Be aware that use of certain clean-

ers, lubricants, or food stuffs, includ-

ing Simple Green and Pedro’s Bike

Lust, may damage the paint. Please

note that paint damage is not cov-

ered under the warranty. Clean the

frame with mild soap and water.

Bike Set-Up Tips and Tricks

Hakkalügi

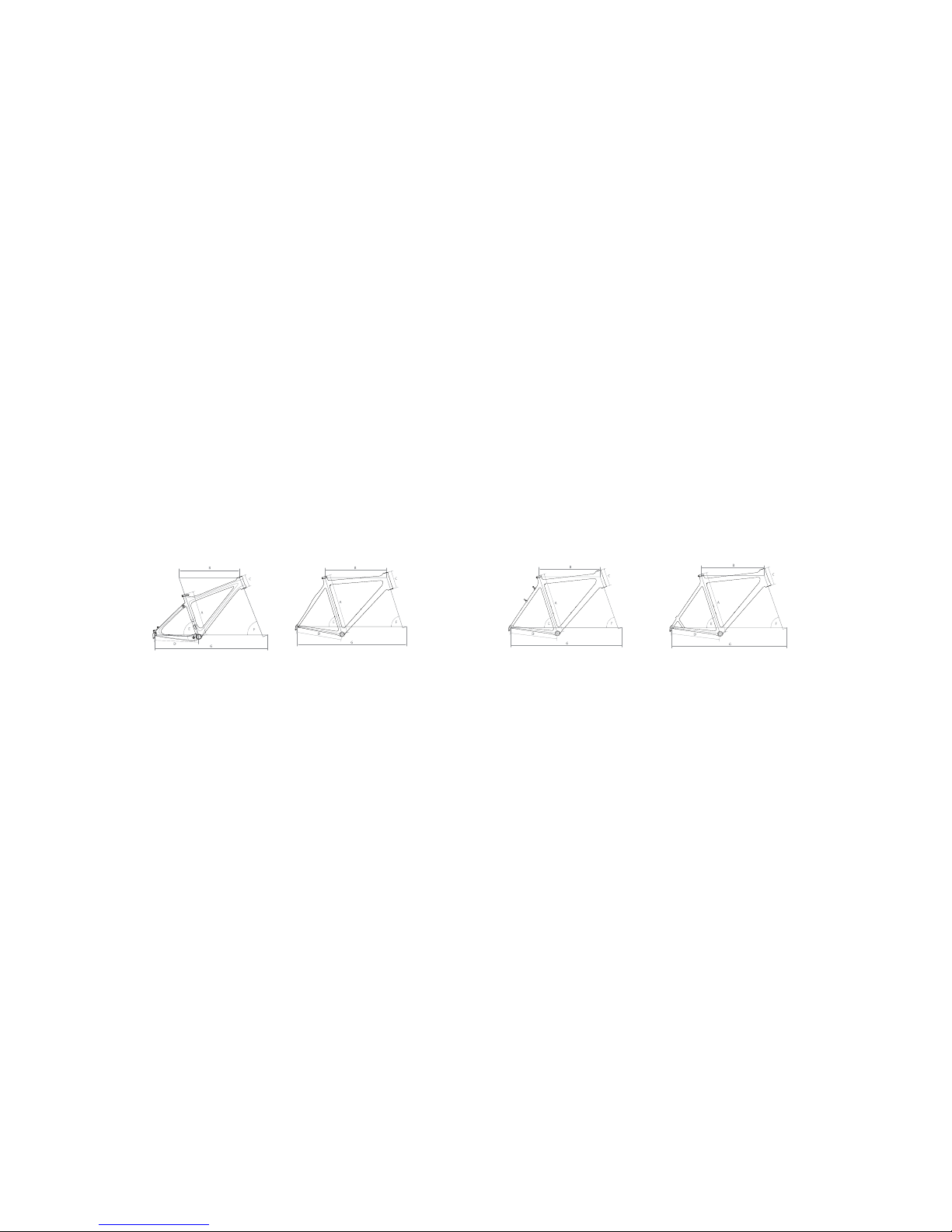

Building a Hakkalügi from a frame to

a complete bike is straightforward,

using standard practices. Be sure

to use assembly lube on a carbon

seatpost. The integrated headsets use

more preload than you might be used

to. If you hear any creaking in the

head tube area after your first ride,

simply increase the headset top cap

tension slightly, until the creak goes

away.

Use an approved fork, please call for

a current list: 831–461–1435.

Brake Set-Up:

Adjust the pads so the front of the

pad contacts first. This will help to

reduce noise and shuddering. You

can also trim trailing edge with a

razor blade if needed to stop shud-

der. Another way to improve brak-

ing performance is to make sure the

straddle cable is straight with minimal

slack. A higher straddle placement in

front improves modulation.