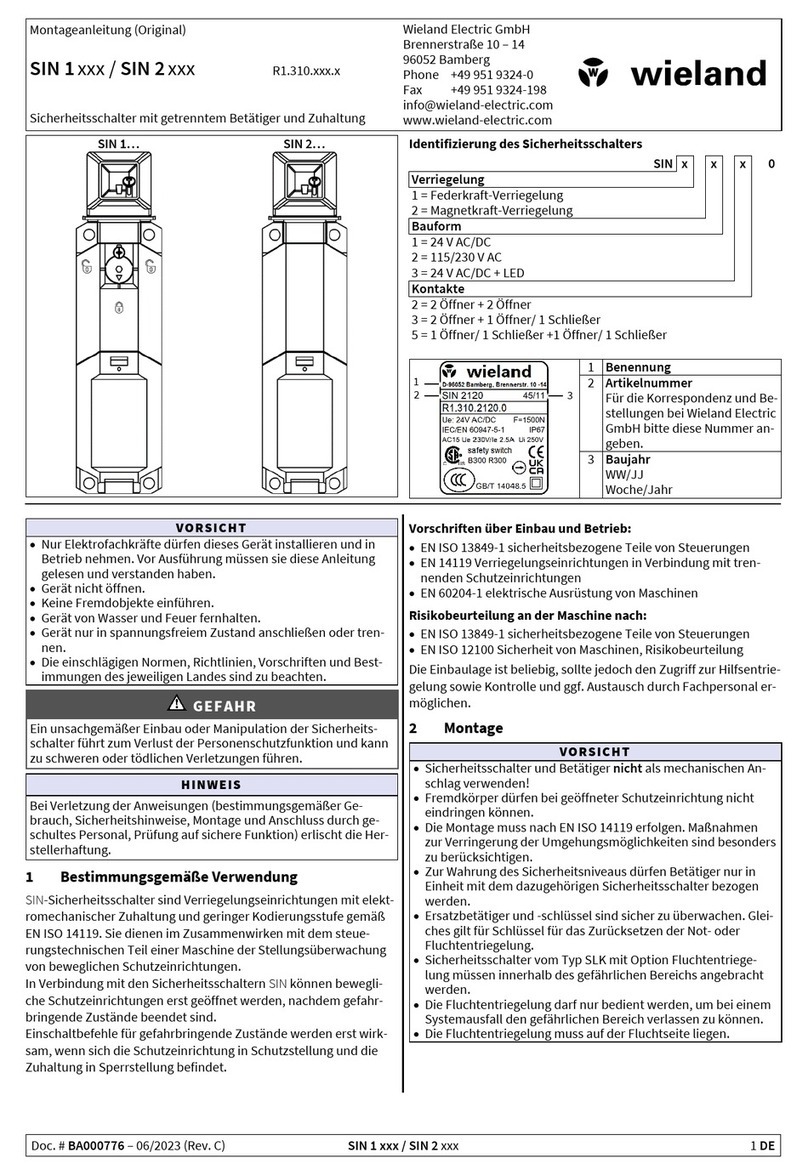

Installation instructions (translation from original)

SIN 1 xxx / SIN2 xxx 83.xxx.xxxx

Safety switch with separate actuator and guard lock

Brennerstraße 10-14

D-96052 Bamberg

Tel. +49 (0) 951 / 9324 -0

Fax +49 (0) 951 / 9324 -198

www.wieland-electric.com

Doc. # BA000776 – 10/2015 (Rev. B) SIN 1xxx/ SIN 2xxx EN 8

Safety switch identification

Article number

Please quote this

article number in all

corre

spondence and

when placing orders

with Wi

eland Electric

/JJ

•Only trained electricians may install and commission this

device. They must have read and understood this instruction

manual before they carry out installation.

•Do not open the device. Do not insert any foreign objects.

Keep the device away from water and fire.

•Only connect or disconnect the device if it has been de-

energised.

•The relevant standards, directives, regulations and provisions

of the particular country are to be observed. Installation,

commissioning, modification and retrofitting must only be

performed by a qualified electrician.

•In the case of improper use or any use other than for the

intended purpose, the device must no longer be used and any

warranty claim is void. Invalidating causes can be: strong

mechanical loading of the device, such as occur when falling

or voltages, currents, temperatures, humidity outside the

specifications.

DANGER

Improper installation or manipulation of the safety switch

renders the personal protection function useless and can cause

serious injury or accidental death.

Failure to follow these instructions (intended use, safety instruc-

tions, installation and connection by trained personnel, safe

function test) will invalidate any liability.

1Intended use

SIN safety switches are locking fixtures with an electromechanical

latching device and low level coding according to EN ISO 14119.

Interacting with the control system of a machine they are used to

monitor the position of moving safety guards.

In connection with the safety switches SIN, moving safety guards

can only be opened if no hazardous conditions are present.

The actuating signals in relation to hazardous situations are only

effective when the safety guard is in active position and the

latching device is in lock position.

Standards governing installation and operation:

•EN ISO 13849-1 Safety components of control systems

•EN 14119 Locking devices in connection with separating safety

guards

•EN 60 204-1 Electrical machine equipment

Risk assessment at the machine in accordance with:

•EN ISO 13849-1 Safety components of control systems

•EN ISO 12100 Machine safety, risk assessment

The safety switch can be installed in any position that enables

access to the auxiliary release mechanism as well as its inspection

and, if necessary, replacement by authorised technical personnel.

2Installation

•Do not use the safety switch and actuator as a stop!

•Foreign particles must be prevented from entering the actuator

opening when the safety guard is open.

•Installation must be carried out in accordance with EN ISO

14119. Particular attention must be paid to measures designed

to reduce the possibilities of bypassing the system.

•To maintain the safety level, the actuators can only be ordered

with the belonging safety switch in one unit.

•Replacement actuators and keys have to be securely monitored.

The same applies to keys for resetting the emergency release or

escape release function.

•The safety switch must not to be used as mechanical limit stop.

•The SLK safety position switch with escape release option must

be installed within the hazardous area.

•The escape release option can only be used in order to quit the

hazardous area in case of a system failure.

•The escape release must be on the escape side.