English

Installation and operating instructions Wilo VR System 19

4 Description of the product and accessories

4.1 Description of the control device

4.1.1 Function description

The control device is for controlling and regulating

pressure boosting systems consisting of pumps

with integrated frequency converters or external

frequency converters. The pressure of a system is

controlled load-sensitively with appropriate signal

transmitters. The controller affects the frequency

converter which has an effect on the pump speed.

A change in speed changes the volume flow and

thus the rated motor power of the single pumps.

Depending on load requirements, pumps and asso-

ciated frequency converters are started or stopped.

The control device can control up to 4 pumps or

frequency converters.

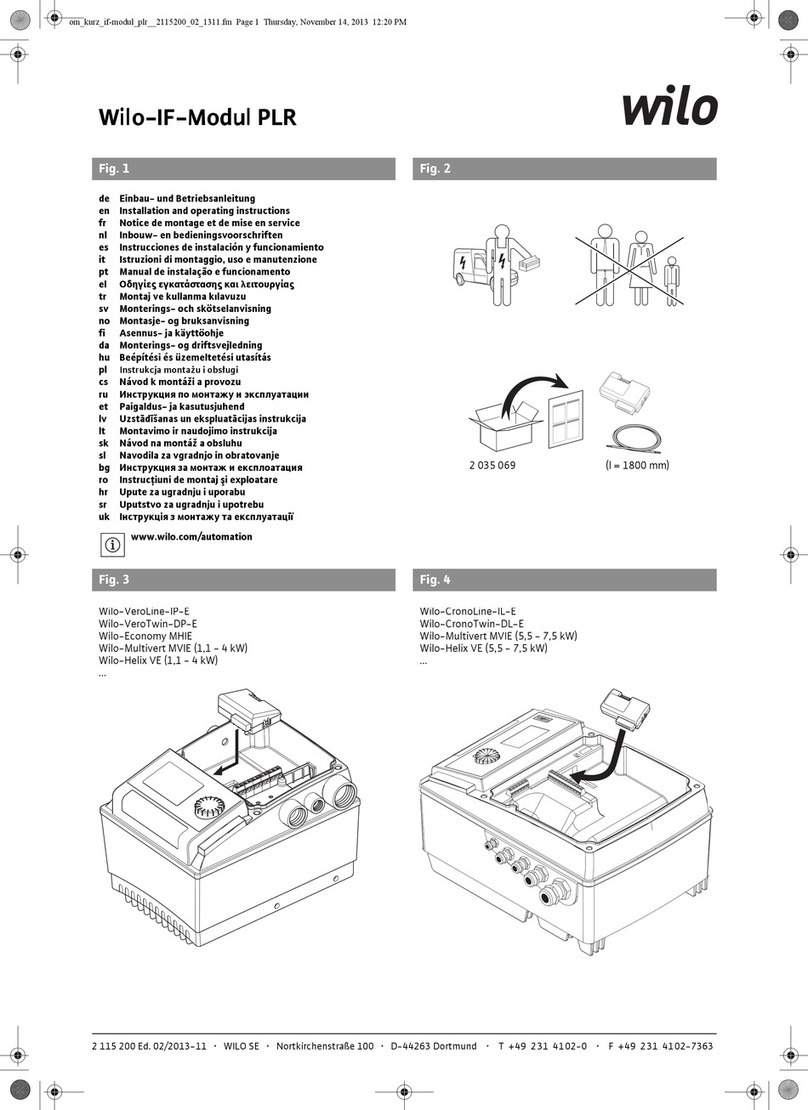

4.1.2 Design of the control device

The standard control device consists of the fol-

lowing individual components (Fig. 2):

NOTE!

Fig. 2 merely shows an example.

The actual design may vary

according to the plant configuration.

The installations are in a sheet metal housing,

painted in RAL 7035 (textured):

•Main switch (item 1):

Disconnectsthe powersupply andis for connecting

the mains supply.

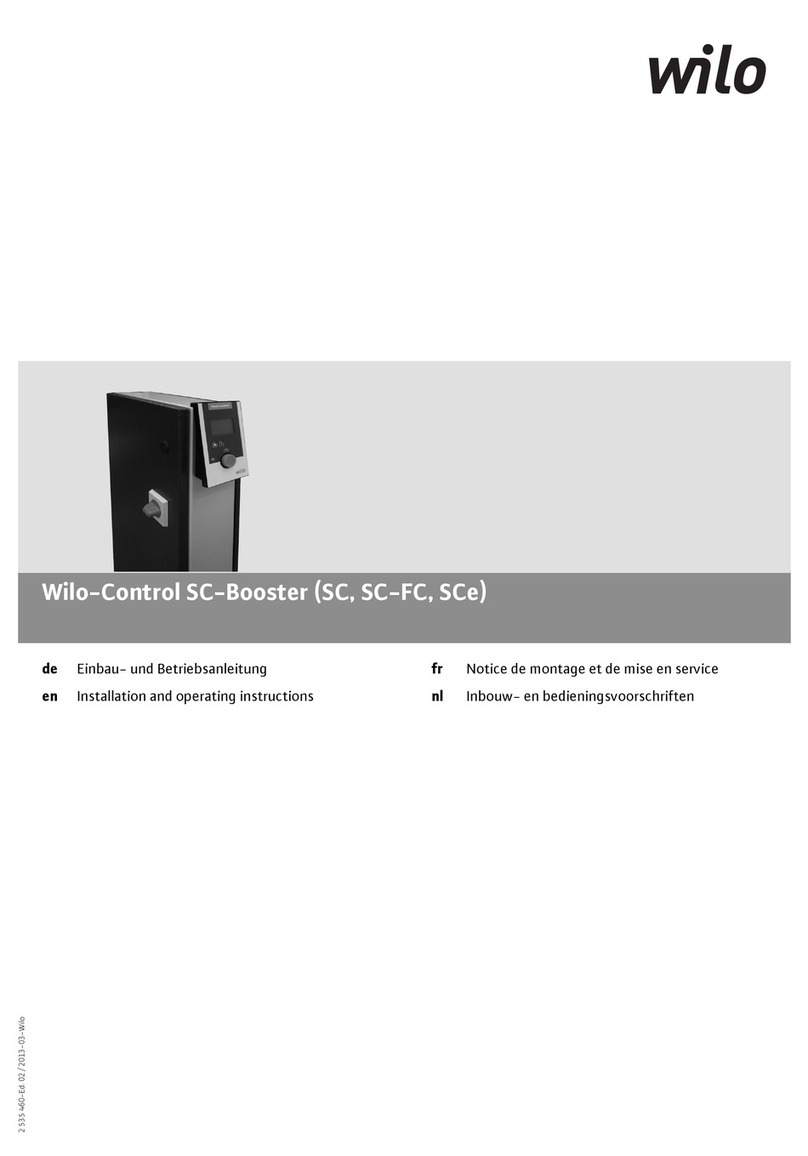

•Base board (item 2, design according to Fig. 3):

Power supply unit for the control device's low-

voltage part, fuses 6.3x32 (item 1), connector strip

forthedisplay board, microcontroller board (item 3)

and individualrun andfault messageboard (item 4).

In addition, connection terminals for the power

supply (Fig. 3, item 8) and for the external signals

(items 6+7), and slide switch (item 5) for every

pump for the system's emergency operation func-

tion and a potentiometer (item 5a) for setting the

speed.

•Microcontroller board (item 3):

Microprocessor and plug connections for the base

board and display board and DIP switches 1...8.

• Display board:

For LCD display, rotary knob and LEDs.

•Circuit breaker (item 5):

Fuse protection for the power supply of electronic

modules.

•Circuit breaker (item 4):

Fuse protection and connection of the single pumps

with frequency converter drives.

•Individual run and fault message board (item 6):

Optional, for the provisionof changeover contacts

for the run and fault signals of each pump and for

low water protection (see also Fig. 5).

Chapter 5 provides more information.

4.1.3 Operating modes of the system

Normal operation

An electronic pressure transducer provides the

actual system pressure value as 4 – 20 mA current

signal. Then the controller maintains the system

pressure constantly at the setpoint by means of

the comparison of the setpoint/actual value.

If there is no “External Off” signal and no fault, a

pump starts if required. The pump speed depends

on consumption.

If the required output cannot be covered by this

pump, another pump is started, the speed of which

is then controlled according to the reduction to

the pressure setpoint. Pumps, which are already

running, keep running at maximum speed. A zero-

flow test prevents the activation of a further pump,

provided there is no pressure drop.

If demand decreases to such an extent that the

controlling pump runs in its lowest performance

range and is not needed to cover demand, this

pump will be deactivated and the control function

is assigned to another pump which has previously

been working at maximum speed.

When the supply voltage is re-established after

deactivation or a power failure, the control device

is automatically switched to the previously set

operating mode.

Zero-flow cut-off

If only one pump is operated, whether a reduction

still applies is checked every 60 seconds. For this,

the pressure setpoint is increased slightly for a short

while and then reset again. If the actual system

pressure then remains at the higher level, there is

zero flow. The pump is then switched off after an

adjustable follow-up time, T2. If the pressure falls

below the setpoint, the system restarts. If T2 = 0

is set, zero-flow detection and deactivation are no

longer active.

Pump cycling

Two mechanisms are applied in order to ensure that

the loads on all pumps are distributed as evenly as

possible and to adjust the running times of the

pumps.

On the one hand, pump cycling is enforced after

a running time of 6 hours, including during normal

operation. For this, during peak-load operation,

the pump previously operated as peak-load pump

assumes the control function, which follows the

pump previously operated as base load (control)

pump. On the other hand, when the system is

restarted (e.g. after zero flow, “External Off”),

the pump that follows the pump last switched off

is started (provided there is no pump fault).