© by WilTec Wildanger Technik GmbH Item 61852, 61899 Page 4

http://www.WilTec.de

http://www.aoyue.eu 10 2021-1

http://www.teichtip.de

Important safety information

Warning! Read and understand all instructions. Non-compliance with any of the following

instructions might lead to serious injuries.

•The warnings, safety advises, and instructions cannot cover all possible situations or conditions

probably arriving during use of the device. Therefore, always make sure to use the device with

caution, pay attention to your surroundings, and use the tool in a safe way and with common

sense.

•Never allow anyone to use or assemble the device that has not read the entire user’s manual

and developed a proper comprehension of the functions of the device.

•The device must not be modified in any way. Unauthorised modifications might impair the func-

tionality and/or safety of use and reduce the lifetime of the product. The product has been de-

signed to serve in a well-defined way.

•Use the tool that matches the respective job to do. Never try to use a small device for a job that

should be done with large industrial devices. The tool will do a safer and quicker job when used

for its intended purpose.

Safety in your working area

•Before every use, inspect your working area. Keep your working area clean, tidy, and well illu-

minated. Untidy, damp, or dark working area invites accidents.

•Make sure that the tool does not get in contact with any power source. Accidental contact might

lead to electrical shocks.

•Keep children and bystanders away from your working area while using the device. Do not allow

children to use the device.

•Pay attention to all sorts of power cables, circuits, water conduits, and other mechanical dangers

in the working area. Some of these dangers, hidden under or behind the working surface, might

not be visible. This can lead to injury and/or damage.

Personal safety

•Always pay attention and fully concentrate on your work. Therefore, always use the device with

caution. Do not use the device when being tired or under the influence of alcohol, drugs, or

medicine. A moment of inattention, the small it be, might lead to serious injuries during use of

the device.

•Wear appropriate clothing. Do not wear loose clothing or jewellery. Tie long hair together, as it

could get into moving parts. Keep hair, clothing, and gloves away from moving parts.

•Wear safety goggles with side protection or a protection that covers the entire face to be pro-

tected from metal particles ejected. Use a dust mask when performing work that generates a lot

of dust. Also wear non-slip shoes, a hard hat, and robust gloves. Use dust collecting devices

and, if necessary, wear an ear protection. This applies to all persons within the working area.

•Do not stoop down too far. Ensure a safe stand and keep your balance.

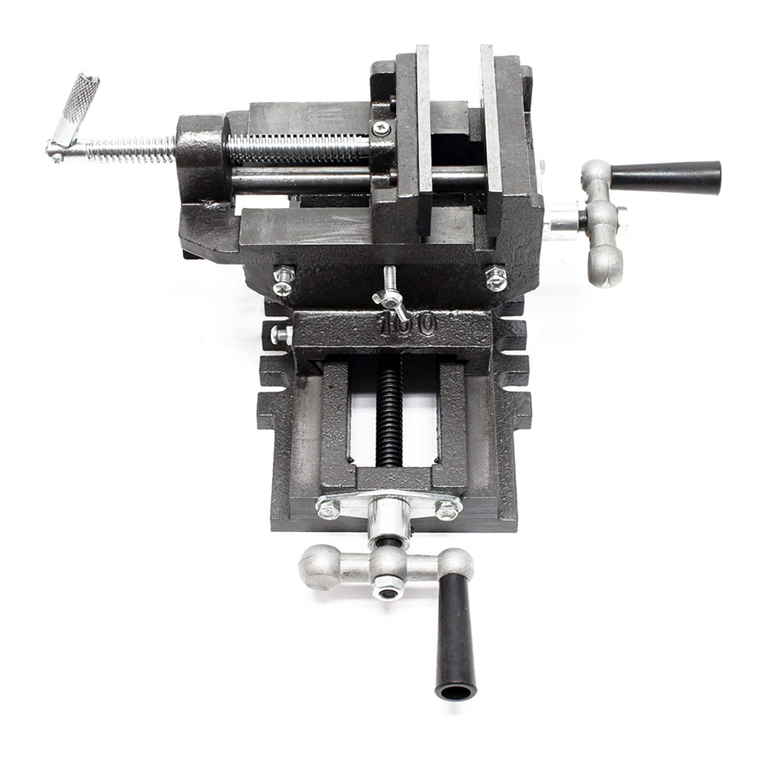

•Secure the work pieces with clamps and a vice, not with your hand. When doing so, you will

have both hands free to use the device.

Use and maintenance

•Do not apply too great a force when using the device. Devices and tools work more safely and

more reliably when being used for their respective intended purpose. Plan your work and use

the suitable devices and tools for it.

•Before operating the device, check it for damaged parts. Thoroughly check if the device or tool

functions properly and can be used as intended. Immediately replace damaged parts. Never

use the device if parts are damaged.

•Store the device when it is not used. Keep it in a dry, safe location and out of children’s reach.

Before storing or re-using the device or tool, check it for damages.