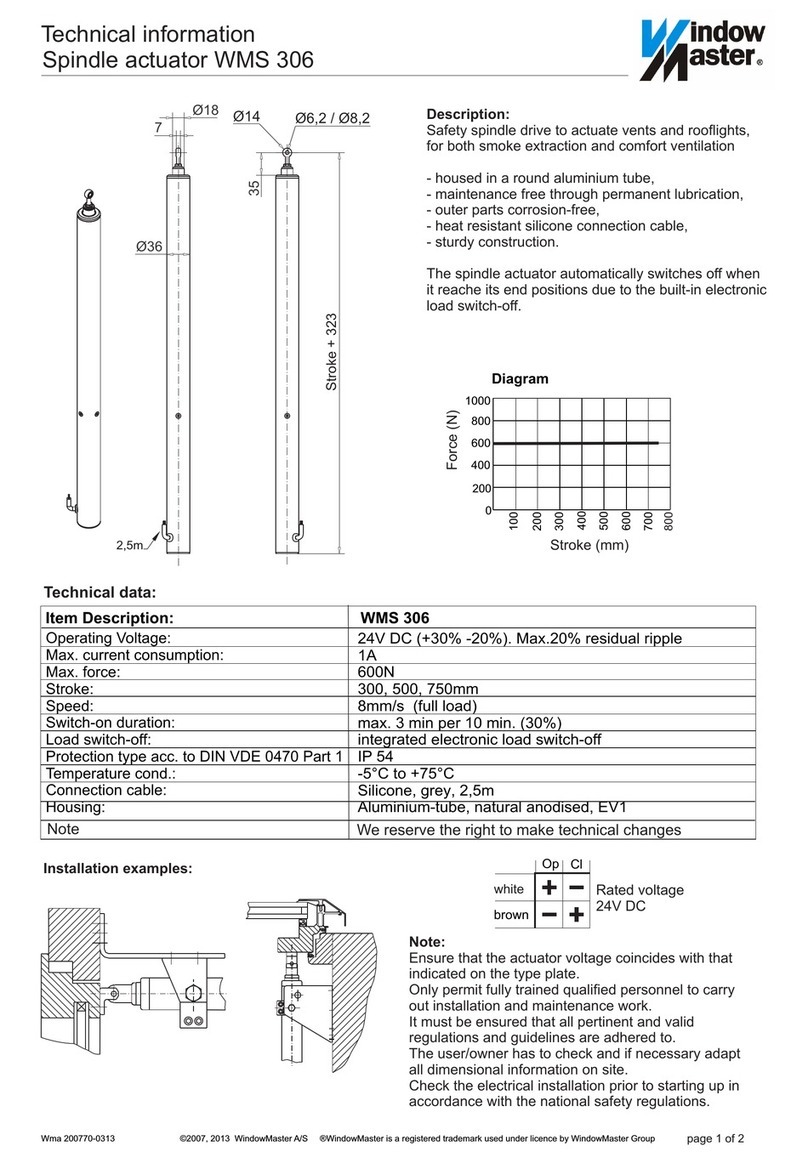

Technical information

Page 2 of 2

Spindle actuator WMS 306

Installation:

The actuator can be installed in different ways.

The criteria to be taken into account include the

different pressure and pulling forces to be applied or

the varying fitting situations on site.

The actuator can be installed at the actuator end

using a clamping ring and corresponding brackets, or

using an eyebolt.

Ensure that all fastening and clamping screws are

properly tightened.

Settings and adjustments are made on site.

To position the actuator, without power, manually

adjust the spindle rod by turning it to it’s end position,

please be aware the spindle rod can run in a further

5mm when power is eventually applied.

If power is available, power the actuator to its end

stop the position actuator to vent.

The electrical connection is to be made in accordance

with the documentation for central control unit.

Never access the actuator without the corresponding

motor electronics.

Start-up:

Ensure that the actuator motors are powered in a

voltage range of 19-32V / DC and at a maximum

residual ripple of 20%.

The running direction of the actuators

(OPEN/CLOSED) changes as the motor voltage

polarity changes.

Ensure that a min. 0.5 s delay is allowed between the

OPEN and CLOSED commands.

Only control the actuators in their self-locking mode.

An activated CLOSED command must be followed by

an OPEN command.

Avoid retriggering of actuators which are run in the

load switch-off mode. This could cause damage to the

actuators.

Ensure that the power supply to the central control

unit on site is such that the start torque of the

actuators can draw up to four times the overall power

for a short period (min. 1 s) without the motor voltage

dropping below 24V/DC.

Note:

Possible danger to persons caused by electric motor

driven sash and frame.

The high forces occurring in the automatic mode

can cause enjury.

Actuators may extend into the room during opening,

for this reason, care needs to be taken prior to

starting up the actuators to exclude the risk of injury.

With vents tilting inwards or outwards, the vent must

be protected from dropping down once the actuator is

unhooked (e.g. for window cleaning).

For safety reasons we recommend the use of

restrictors

In the event that vents or rooflights are subjected to

high rain or wind loads , we recommend connecting

the central control unit to a rain and wind sensor

which will automatically close the vents.

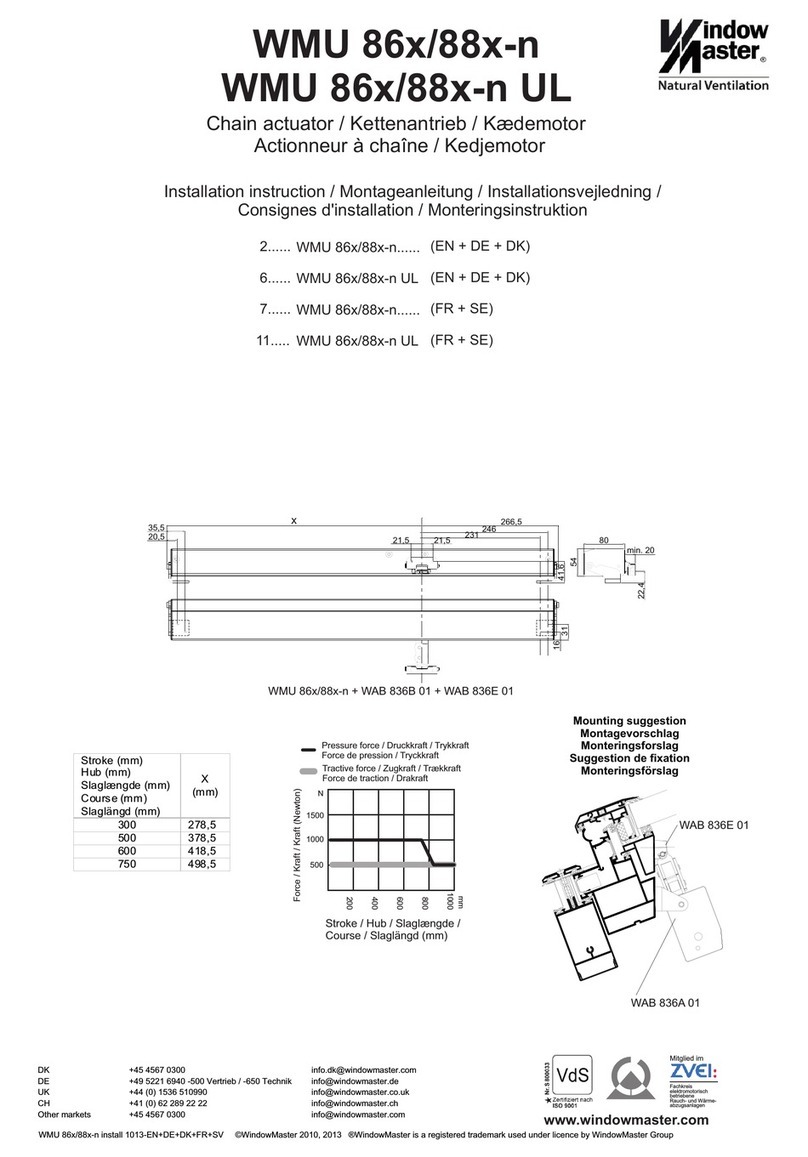

WSB 300 0011

Pushrod bracket

WSB 300 0010

Pushrod bracket

WSB 300 0012

Pushrod bracket

Wma 200770-0818 ©2007, 2018 ®WindowMaster is a registered trademark used under licence by WindowMaster International A/S

WSB 300 0004

bottom eyebolt

fastening

WSB 300 0001

Clampring + bracket

WSB 300 0002

Clampring + bracket

WSB 300 0003

Clampring + bracket

WindowMaster A/S

Skelstedet 13

2950 Vedbæk

Denmark

+45 45 67 03 00

Head office:

CH: WindowMaster AG

+41 (0) 62 289 22 22

DE: WindowMaster GmbH

+49 (0) 40 87 409 560

UK&IE: WindowMaster Control Systems Limited

+44 (0) 1536 614 070