https://wiki.wit-motion.com/english

WhatsApp:+86 13652339539 E-mail:support@wit-motion.com Web:https://wiki.wit-motion.com/english

Catalog

1 Description...................................................................................................- 3 -

2 Product Size.................................................................................................- 3 -

3 Features........................................................................................................- 4 -

4 Axial Diron.................................................................................................. - 4 -

5 Method.........................................................................................................- 5 -

5.1 Connect App......................................................................................- 5 -

5.2 Clibration method..............................................................................- 8 -

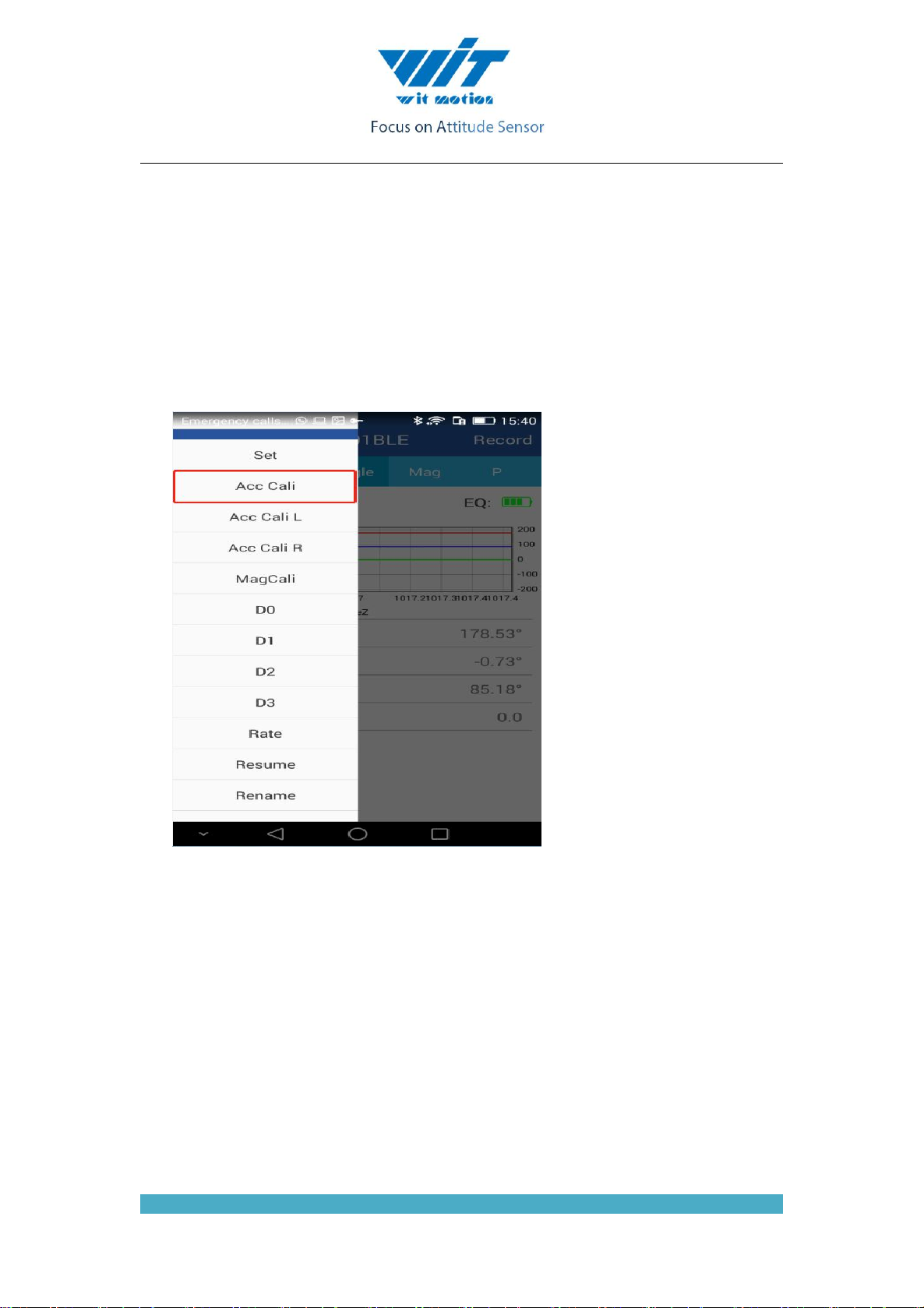

5.2.1 Acceleration calibration............................................................ - 9 -

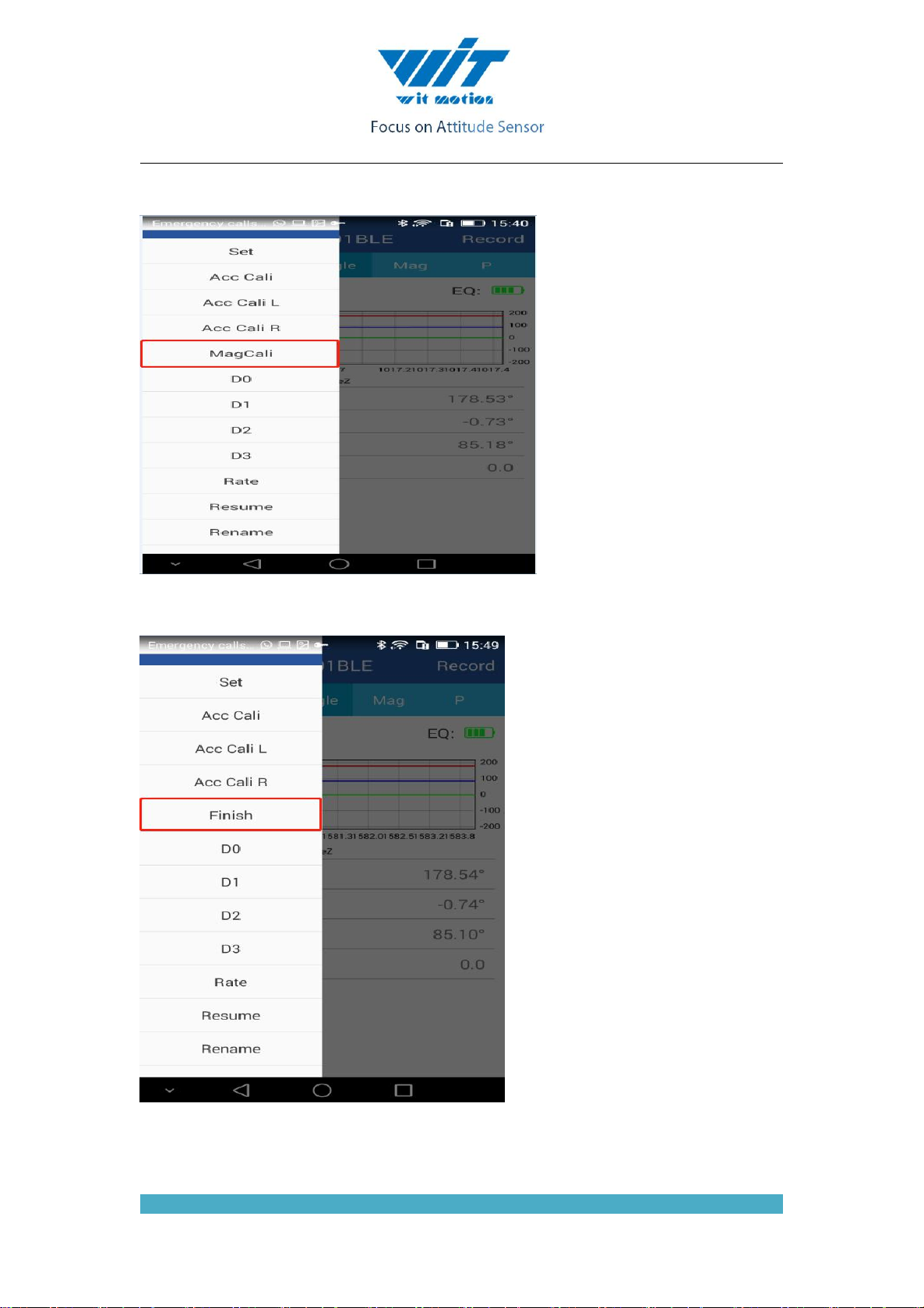

5.2.2 Magnetic Calibration.................................................................- 9 -

5.3 Connect to PC software...................................................................- 11 -

5.3.1 Calibration by Instruction........................................................- 15 -

5.4 Restore Factory Setting................................................................... - 15 -

5.5 Sleep/ Wake up................................................................................- 15 -

6 Communication Protocol...........................................................................- 15 -

6.1 Module to APP................................................................................ - 16 -

6.1.1 Acceleration, Angular velocity, Angle, Data pack(default).... - 16 -

6.1.2 Single Return Register Data Packet........................................ - 17 -

6.2 APP to Module................................................................................ - 19 -

6.2.1 Read register value.................................................................. - 19 -

6.2.2 Accelerometer Calibration and Magnetic Calibration............ - 20 -

6.2.3 Save Settings........................................................................... - 20 -

6.2.4 Set Return Rate........................................................................- 20 -

Set Port D0..........................................................................................- 20 -

Set Port D1..........................................................................................- 21 -

Set Port D2..........................................................................................- 21 -

Set Port D3..........................................................................................- 21 -