Table of contents

1 Product description................................................................ 5

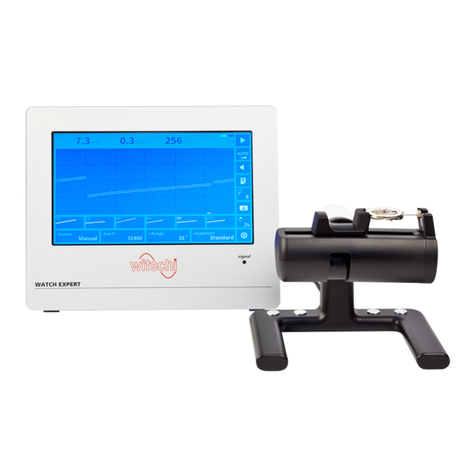

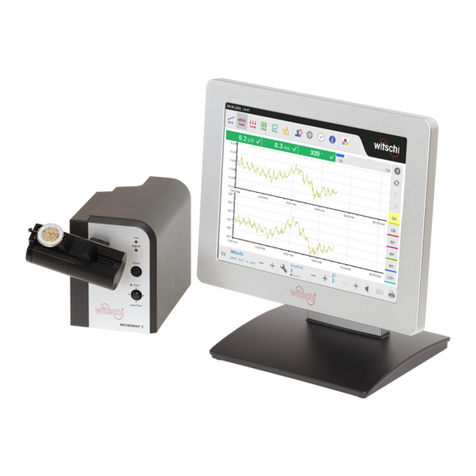

1.1 Overview......................................................................... 5

1.2 Scope of delivery............................................................ 8

1.3 Software.......................................................................... 8

1.4 Modes.............................................................................. 8

1.5 Technical data.............................................................. 10

2 Safety..................................................................................... 12

2.1 Symbols in this document.......................................... 12

2.2 Risk of material damage............................................ 13

2.3 Intended use................................................................. 13

2.4 Owner’s responsibilities.............................................. 14

2.5 Personnel qualifications.............................................. 15

3 Commissioning the ChronoMaster................................... 16

3.1 Unpacking the ChronoMaster................................... 16

3.2 Requirements for the location................................... 17

3.3 Installing the software................................................ 18

3.4 Connecting the ChronoMaster.................................. 20

4 Performing a measurement................................................ 21

4.1 Configuring measurement settings.......................... 21

4.2 Positioning the watch and starting a measure-

ment automatically..................................................... 21

4.3 Controlling the measurement using control keys.. 25

4.4 Monitoring and configuring the measurement...... 26

5 Transportation and storage of the ChronoMaster.......... 27

5.1 Shutting down the ChronoMaster............................ 27

5.2 Transportation and storage of the Chrono-

Master........................................................................... 27

6 Maintenance and cleaning of the ChronoMaster........... 29

6.1 Safety during maintenance........................................ 29

6.2 Maintenance schedule............................................... 29

7 Troubleshooting.................................................................... 30

7.1 Error messages in the display software................... 30

7.2 Damage to the ChronoMaster.................................. 30

7.3 Troubleshooting........................................................... 30

8 ChronoMaster disposal....................................................... 31

9 Index....................................................................................... 32

Appendix................................................................................ 35

A Declaration of conformity .................................................. 36

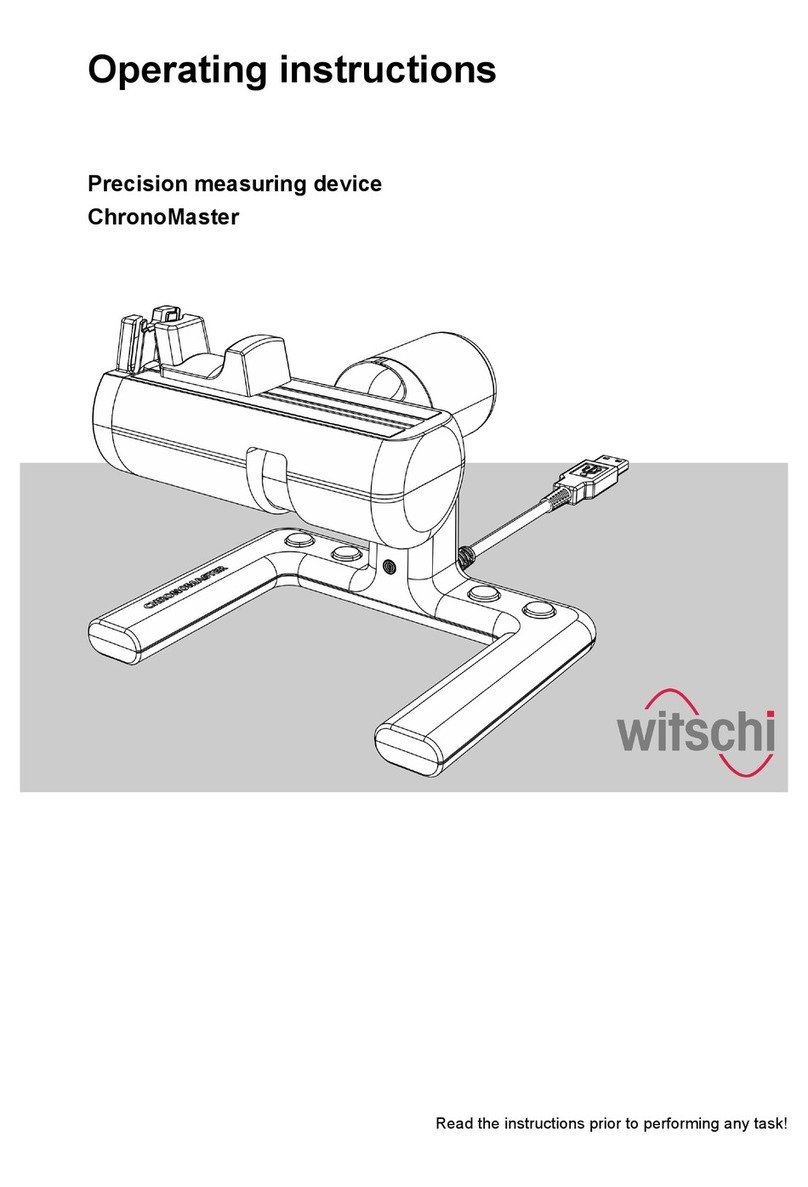

01.09.2020Precision measuring device ChronoMaster4