Do Not Over Tighten Nuts!

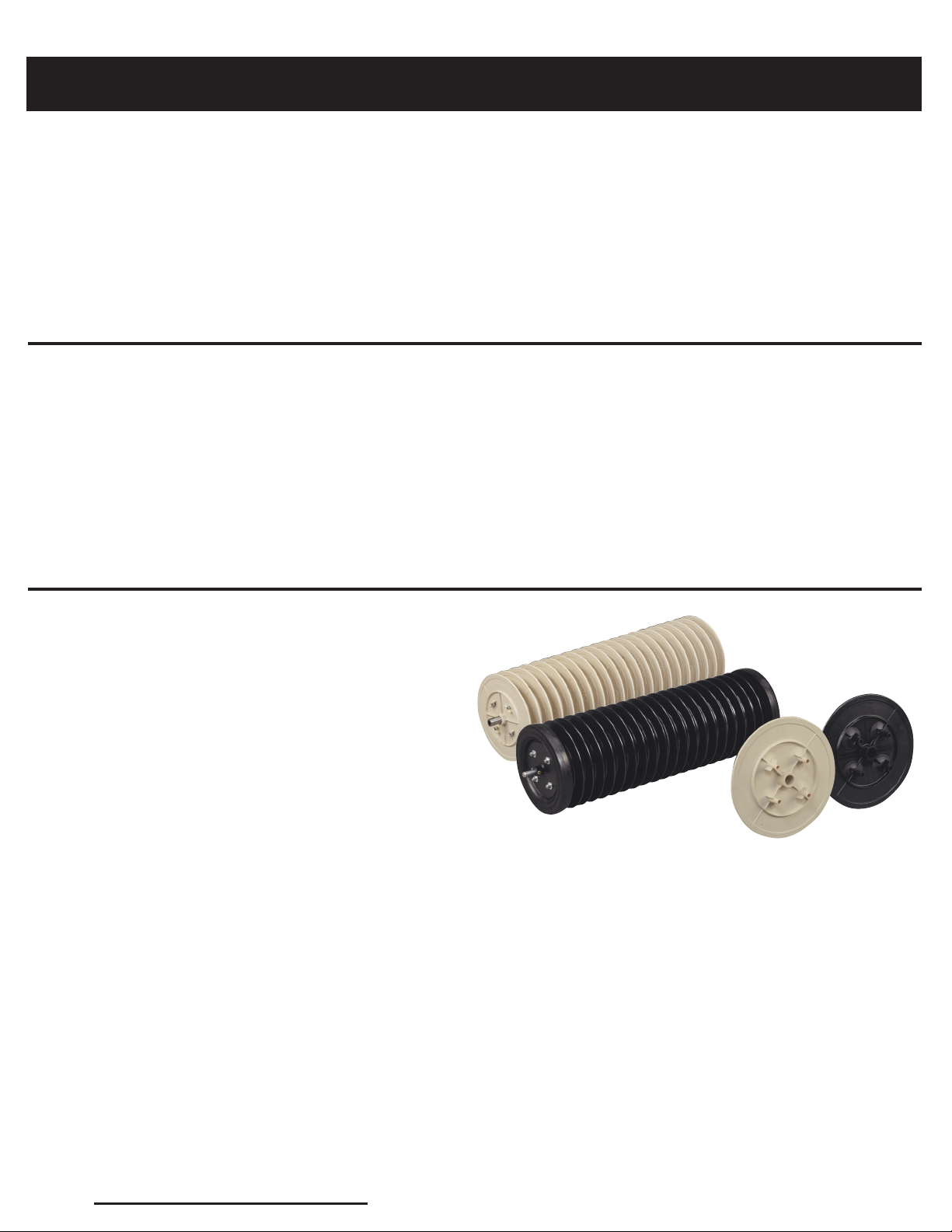

Replacing Worn or Damaged Discs

These instrucons are for replacing worn or

damaged discs of the drum secon.

Preparaons:

1. Remove drum secon from frame.

2. Determine the shortest point to

worn/damaged disc.

3. Remove pillow block bearings from the

axle on the end you are working with by

loosening the set screw.

NOTE: It might be dicult to remove the

bearings because of the beveled edge created

by the set screws.

Removing discs:

1. Remove nylon lock nuts and washers from

e rods.

NOTE: WITTEK uses nylon lock nuts on all nuts

and bolts combinaons. It is recommended

that when replacing the lock nut, a new nylon

lock nut is used. Nylon lock nuts can be

purchased at any hardware store (standard size

of 3/8” is used).

Reassembling discs:

1. Replace disc(s) that were removed.

2. Replace the spacer, wheel only, re and

wheel only.

NOTE: Before replacing the end plate and

pillow block bearings, lightly sand the sha to

smooth out beveled edges or other nicks

created by the set screw (this will make it

easier to replace the end plate and pillow

block bearings).

3. Replace end plate.

4. Replace washers and nuts on e rods.

5. Finger ghten all nuts evenly.

6. Place drum secon on a at surface

(i.e. worktable).

7. Using a golf ball as a guide tool, insert the

golf ball in the space between each disc to

determine that the golf ball ts “snugly”

and that the golf ball does not slide down.

If sliding occurs, reghten the nuts on the

e rods unl you have reached the

desired snugness in each disc secon.

8. Replace nut and bolt on end plate.

9. Replace pillow block bearings.

DO NOT TIGHTEN SET SCREW on the pillow

block bearing.

10. Loosen the set screw on the

pillow block bearing on the other end of

drum secon.

11. Replace drum onto frame of picker.

12. Align the drum secon by centering the

ngers on the frame in each disc secon.

13. TIGHTEN set screws on the pillow block

bearings on both ends of drum secon.

8

2. Remove end plate by loosening and

removing the nut and bolt.

3. Remove the wheel only, re and the spacer.

4. Begin to remove discs unl you reach the

worn/damaged disc.

5. Replace old disc with new disc.