IF THIS APPLIANCE IS NOT PROPERLY INSTALLED, A FIRE MAY RESULT. TO REDUCE THE RISK OF FIRE,

FOLLOW THESE INSTALLATION INSTRUCTIONS. A MAJOR CAUSE OF APPLIANCERELATED FIRES IS

FAILURE TO MAINTAIN REQUIRED CLEARANCES AIR SPACES TO COMBUSTIBLE MATERIALS. DO NOT

PACK REQUIRED AIR SPACES WITH INSULATION OR OTHER MATERIALS. IT IS OF THE UTMOST IMPOR

TANCE THAT THIS APPLIANCE BE INSTALLED ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS.

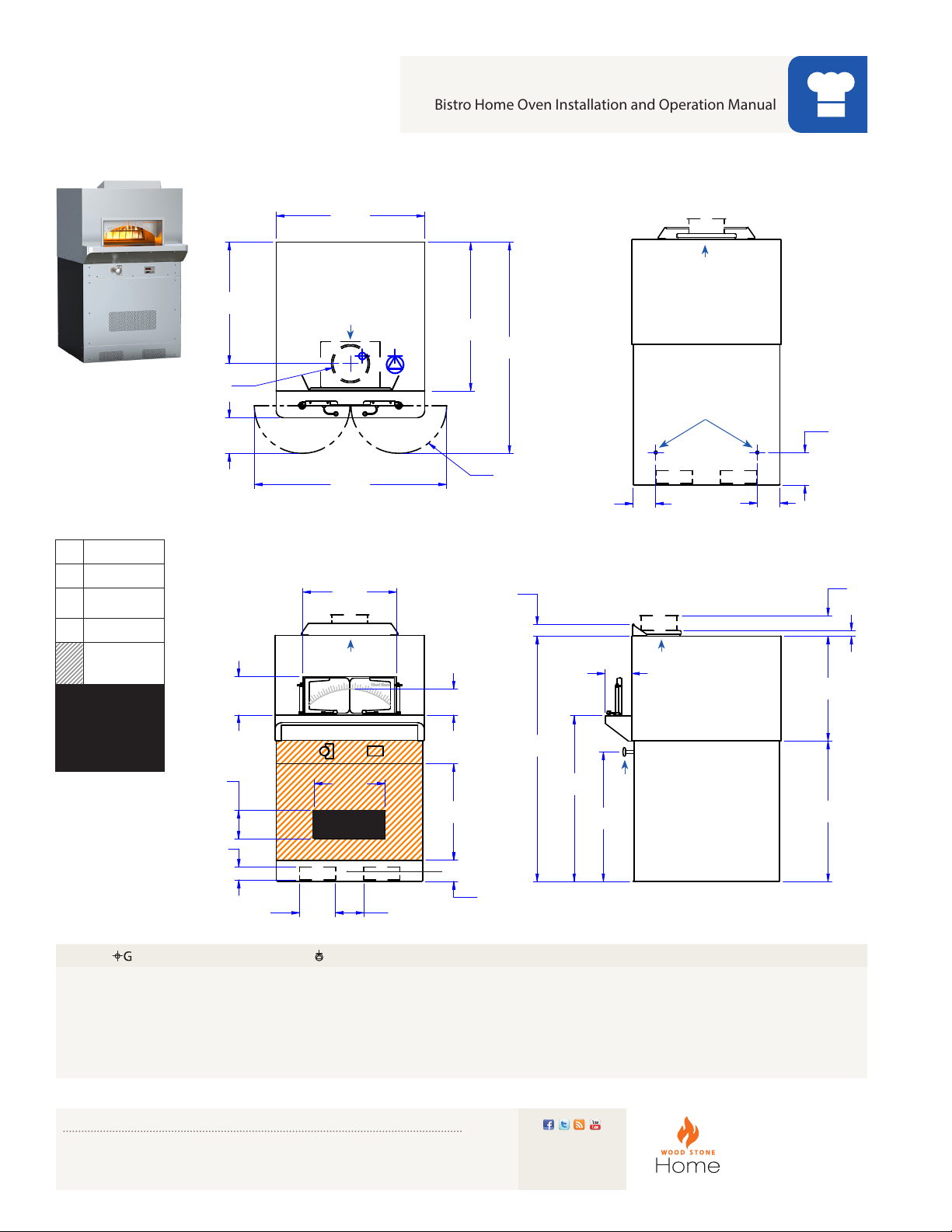

CLEARANCES

1. The Wood Stone Bistro oven must have a minimum 1-inch clearance to combustibles from all sides, and 6-inch

clearance to combustibles from the top. If building materials will contact the oven, they must be completely

non-combustible. Please note that standard Drywall (or Sheetrock) is considered a combustible. When non-

combustible building materials contact the body of the oven, the respective clearances are transferred to those

non-combustibles.

2. Any facade 6 inches to either side of the oven doorway or above, must be constructed of non-combustible

building materials.

3. For gas-only models, this appliance is suitable for installation on combustible oors (convient à l’installation

sur un plancher combustible). As with any cooking equipment, we suggest that care be taken when choosing

the surfaces in front of the appliance to protect them from potential damage from hot, heavy items that may

be removed from the cooking chamber.

For gas/wood combination models, this appliance is suitable for installation on combustible oors (convient

à l’installation sur un plancher combustible). The minimum hearth extension area to be covered with a non-

combustible oor surface must extend 36" in front of and 30" to either side of the oven door opening.

NOTE: For stucco-ready appliances, the same clearances as described above apply. Non-combustible stucco mix

must be used and applied to a minimum thickness of 1". When non-combustible building materials contact the

body of the appliance, the clearances to combustibles are transferred to those non-combustibles.

Dotted area (6" to either

side of doorway and above)

represents space where

facade materials must be

non-combustible.

Hatched area must be left

accessible and unobstructed

(do not cover/facade over)

after installation to allow for

proper airow and service

access.

Maintain 1-inch

minimum

side & back

clearance to

combustible

construction

Note: For ovens listed to burn wood (a “-W” will appear in the model number), this

appliance is suitable for installation on combustible oors. The minimum hearth extension

area to be covered with a non-combustible oor surface must extend 36 inches in front of

and 30 inches to either side of the oven door opening.

Maintain 6-inch

clearance to

combustible

construction

from top and all

sides of the ue

collar*

SEE EXAMPLES OF NONCOMBUSTIBLE AND COMBUSTIBLE WALL CONSTRUCTION ON NEXT PAGE.

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••• ••••••••

•••••••• ••••••••

•••••••• ••••••••

••••••• ••••••••

•••••••• ••••••••

•••••••• ••••••••

••••••••••••••••••••

••••••••••••••••••••

••••••••••••••••••••

••••••••••••••••••••

••••••••••••••••••••

••••••••••••••••••••

••••••••••••••••••••

••••••••••••••••••••

••••••••••••••••••••

••••••••••••••••••••

If oven face is

facaded, leave 1"

minimum clearance

to optional glass

doors

Suitable for installation

on combustible oors.

•••••••••

•••••••••

•••••••••

•••••••••

•••••••••

••••••••

•••••••••

•••••••••

•••••••••

•••••••••

•••••••••

•••••••••

••••••••

•••••••••

*For direct connect

installations, refer

to NFPA 96 and

local codes for duct

installation clearnaces

An ongoing program of product improvement may require us to change specications without notice.

Bistro Home Oven Installation and Operation Manual

woodstonehome.com

info@woodstonehome.com

tf. 800.578.6836

f. 360.734.0223

Wood Stone Corporation

1801 W. Bakerview Rd.

Bellingham, WA 98226 U.S.A.

M0003.23

Rev. July 2020

PG 10 OF 44

Installation Clearances