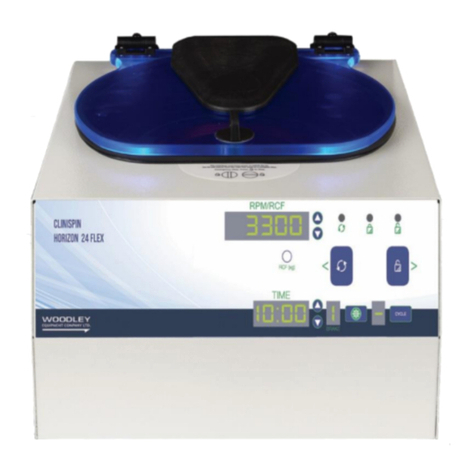

Woodley Clinispin Horizon 6 Flex User manual

Other Woodley Laboratory Equipment manuals

Woodley

Woodley Clinispin CT25 User manual

Woodley

Woodley Clinispin HCT User manual

Woodley

Woodley Clinispin HORIZON 12 Flex User manual

Woodley

Woodley Clinispin HCT II User manual

Woodley

Woodley Clinispin Micro III User manual

Woodley

Woodley Clinispin Horizon 853VES User manual

Woodley

Woodley Clinispin Vet Combi User manual

Woodley

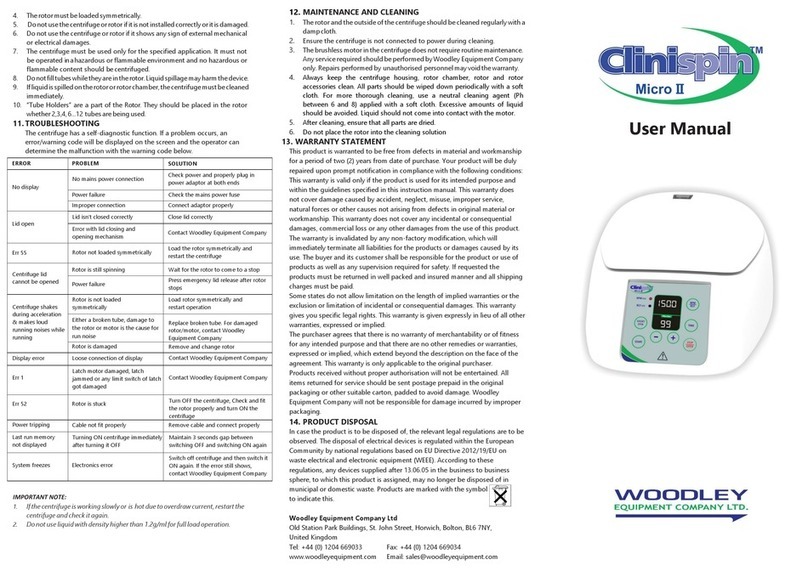

Woodley Clinispin Micro II User manual

Woodley

Woodley CLINISPIN HORIZON 842VES User manual

Woodley

Woodley Clinispin MPC User manual

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual

BD

BD 644787 user guide

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use

Biuged Laboratory Instruments

Biuged Laboratory Instruments BGD 626 instruction manual

VWR

VWR SAS Super IAQ instruction manual

illumina

illumina MiSeqDx reference guide