SETUP LOCATION:

1. Unpack the centrifuge and verify that all of the supplied equipment is present.

2. Choose a setup location which meets the following criteria:

a) Abenchtopclearanceheightof40cmsisrequiredinordertoopenthelid.

b) The clearance envelope is the space around the centrifuge which is required for

safety. Choose a setup location which will allow for a clearance envelope of at least

61 x 61 cms, (with the centrifuge at the center). No person or hazardous material shall

be permitted in the clearance envelope during operation. The operator time within

the envelope shall be limited to the time necessary for loading, unloading and

centrifuge operation only.

c) Proper ventilation is necessary to prevent the overheating of samples as well as

premature failure of the centrifuge. Choose an area which will allow unencumbered

airow.

d) The centrifuge is designed to rest on its four rubber feet. No adjustment is necessary

forlevelingthecentrifuge,however,thesurfaceshouldbeatandlevel.

e) Be sure the outlet is always within reach as the mains lead is the means of

emergency disconnection!

INITIAL SETUP PROCEDURE: If any problems are found during the initial setup

procedure, refer to the troubleshooting section. For further assistance, contact Woodley Equipment

Company LTD. at +44 (0) 1204 669033

1. Plug the female end of the mains Lead into the rear of the centrifuge. Plug the male end into

an approved electrical outlet. For electrical safety, the unit must always be properly

grounded.

2. For operator safety, the locking system is always active; requiring power and direction

from the user to disengage it (the lid also automatically unlocks at the end of a run when

it is safe to do so). To unlock the lid (in order to access the rotor chamber) press the

‘OPEN/STOP’buttononthecontrolpanel.The‘UNLOCKED’indicatorlightshould

illuminate. If it does not, refer to the section on troubleshooting. The lid will remain

unlockedfor15secondsafterpressingthe‘OPEN/STOP’button.

3. Turn the lock counterclockwise and open the lid.

4. Spintherotorbyhand;checkforfreeandlevelrotation.Iftherotordoesnotspinfreely,

refer to the section on troubleshooting.

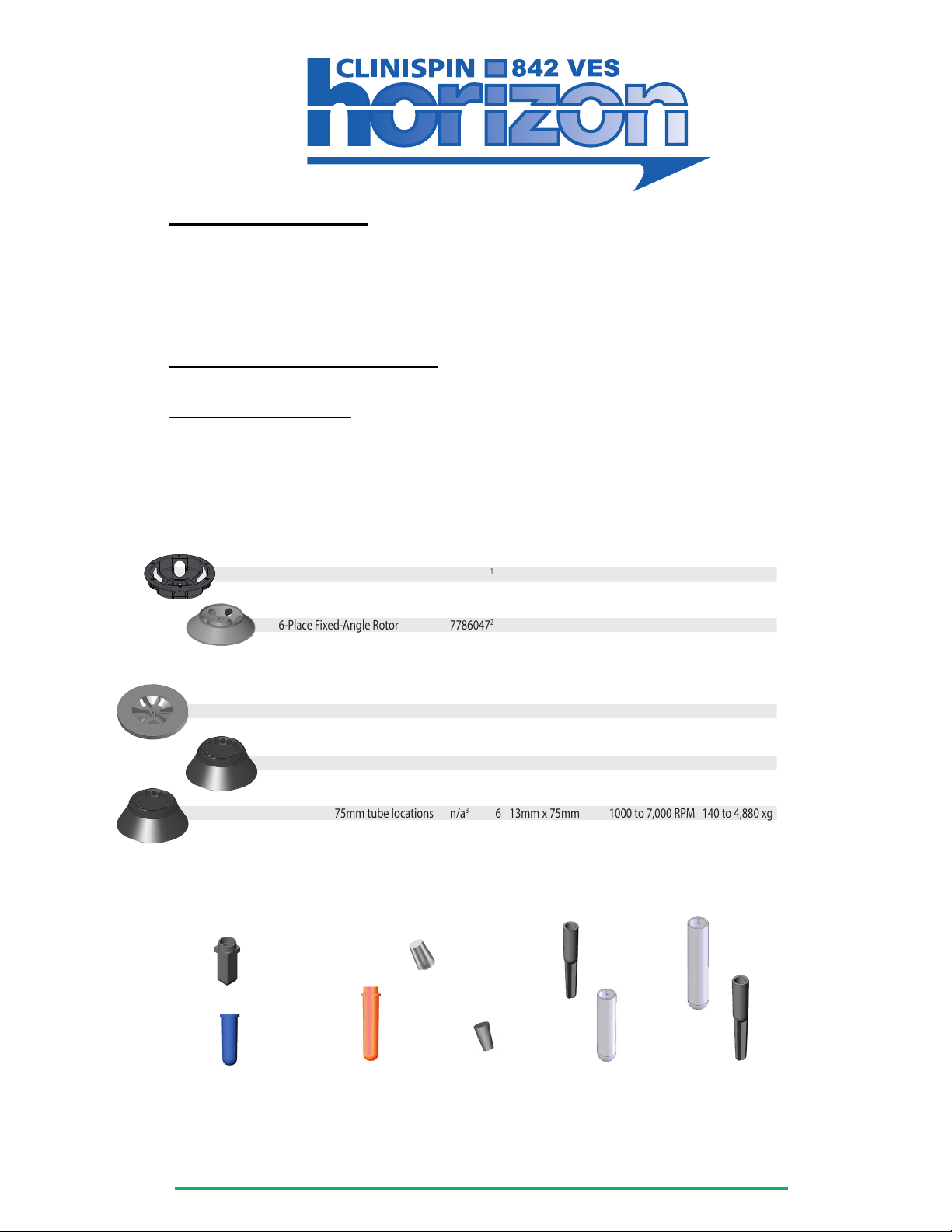

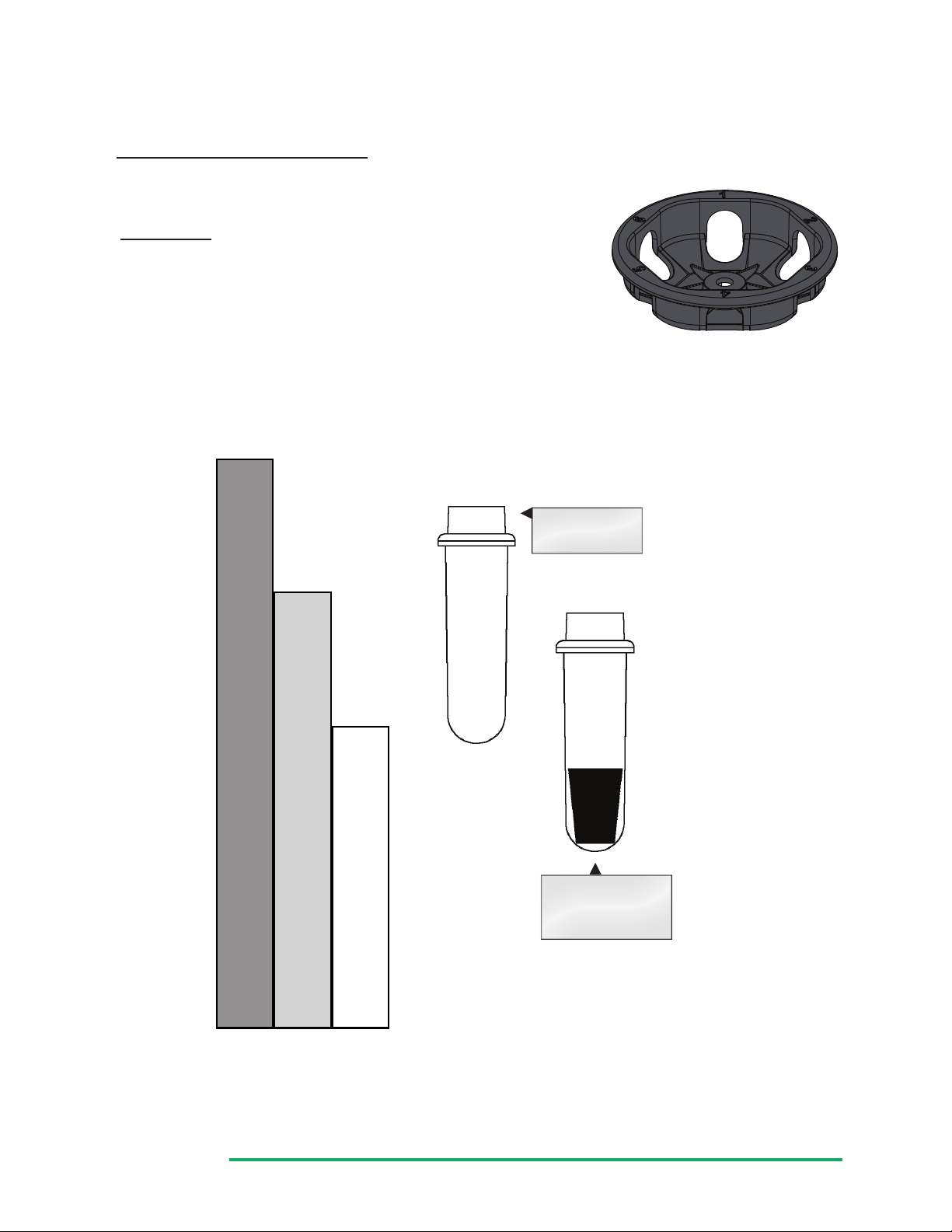

5. Place the test tube holders inside the rotor and verify that they are seated properly.

6. Close the lid. Rotate the lid knob clockwise to its complete stop position. The

’LOCKED’indicatorlightshouldbeilluminated.Ifitisnot,makesurethatthelidis

locked properly. The centrifuge will not run unless the lid is latched properly and the

’LOCKED’indicatorlightisilluminated.

7. UsetheuparrowbuttonnexttotheRPMdisplaytosetthespeedto4000RPM.

8. Initiateatestrunbypressingthe‘START’button.

9. The‘RUNNING’indicatorlightwillilluminate.

10. The test tube carriers will slide up into the horizontal position (horizontal rotor only) and

the unit will accelerate to the current set speed.

11. Listen to the sound of the centrifuge. A smooth whirring sound should be heard. If there

areanyloudorunusualsounds,stopthecentrifugebypressingthe’OPEN/STOP’button

immediately and refer to the section on troubleshooting.

12. Pressthe‘OPEN/STOP’buttontoterminatethetestrun.Therotorwilldeceleratetoa

complete stop and the lid will then unlock automatically for sixty (60) seconds.

13. Take time now to familiarize yourself with the various additional user settings. Turn to

page 11.

14. Thecentrifugeisnowreadyforoperation.

page 6