Operation

Starting The Engine

1

1-2 G3597doc080906 Operation

Engine Start

DANGER! Always be sure the blade is disengaged and all

persons are out of the path of the blade before starting the

engine. Failure to do so will result in serious injury.

DANGER! Operate your engine/machine only in well venti-

lated areas. The exhaust gases of your engine can cause

nausea, delirium and potentially death unless adequate

ventilation is present.

DANGER! Never operate an engine with a fuel or oil leak.

The leaking fuel or oil could potentially come in contact with

hot surfaces and ignite into flames.

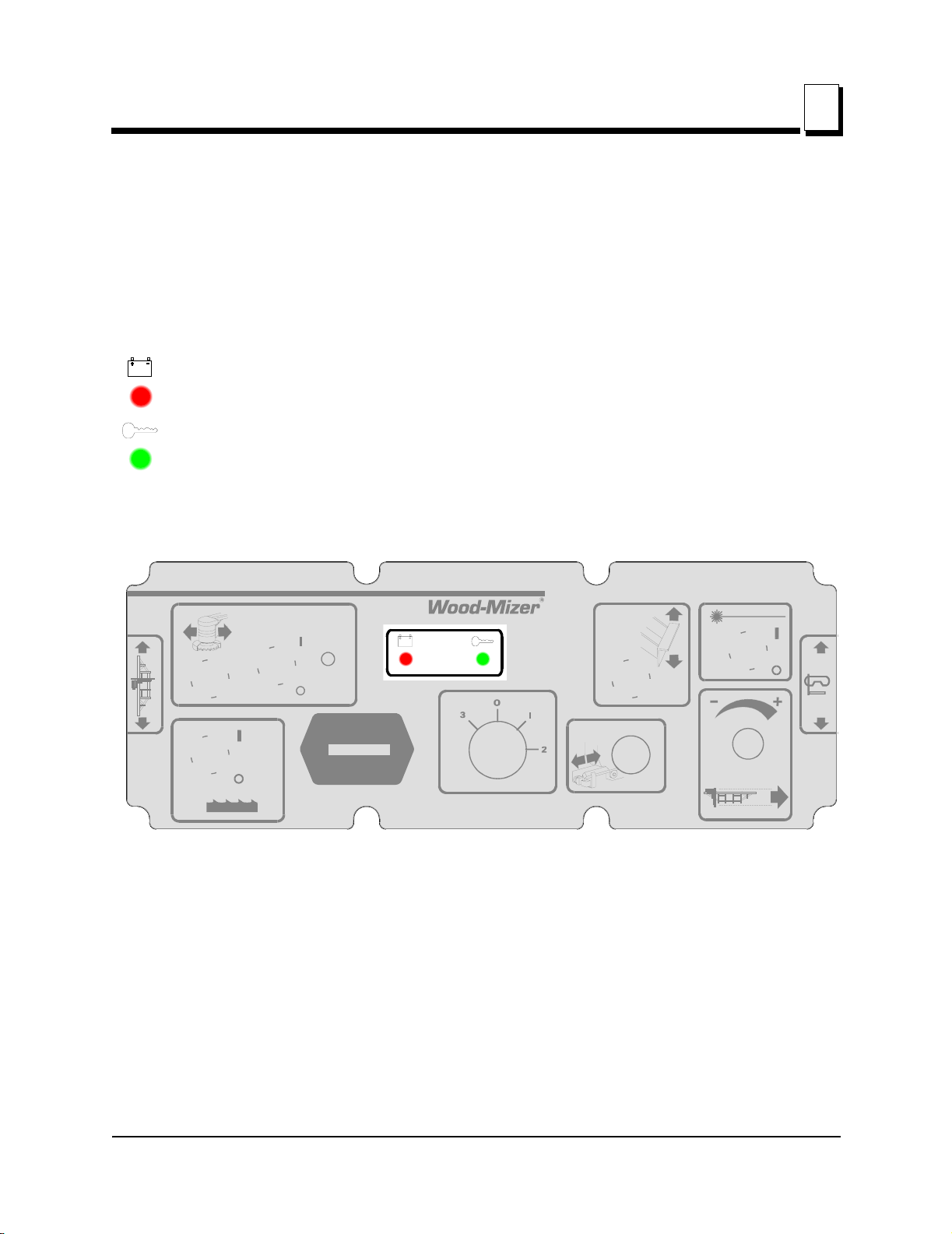

WARNING! Be sure the power feed switch is in the neutral

position before turning the key switch to the on (#1) or

accessory (#3) position. This prevents accidental carriage

movement. which may cause serious injury or death.

WARNING! Do not operate engine without proper and

operational spark arrester/muffler. Sparks emitted from the

engine exhaust could ignite surrounding materials, causing

serious injury or death.

Turn the key switch to the start (#2) position and release.

If the engine needs choking to start, pull the choke cable out until the engine starts. Push

the choke wire in after the engine starts.

For more information, see the engine manufacturer’s operation manual.

LT30 Super rev. F7.00 - F8.01

LT40 Super rev. F8.00 - F9.01

LT30HD Super rev. G1.00 - G2.01

LT40HD Super rev. G1.00 - G2.01

If the fuel tank was recently filled or replaced, squeeze the primer bulb once or twice

before trying to start the engine. NOTE: If pumping problems are experienced, make sure

the out-flow end of the hose line is connected to the fuel filter. If pumping problems are

still experienced, hold the primer bulb in a vertical position while squeezing. This allows

the fuel check valve to operate properly.