Rev 2.0/4-18 1 MRPT1211LDC: #35064

TABLE OF CONTENTS

SPECIFICATIONS............................................................................................................ 3

WARNINGS ..................................................................................................................... 4

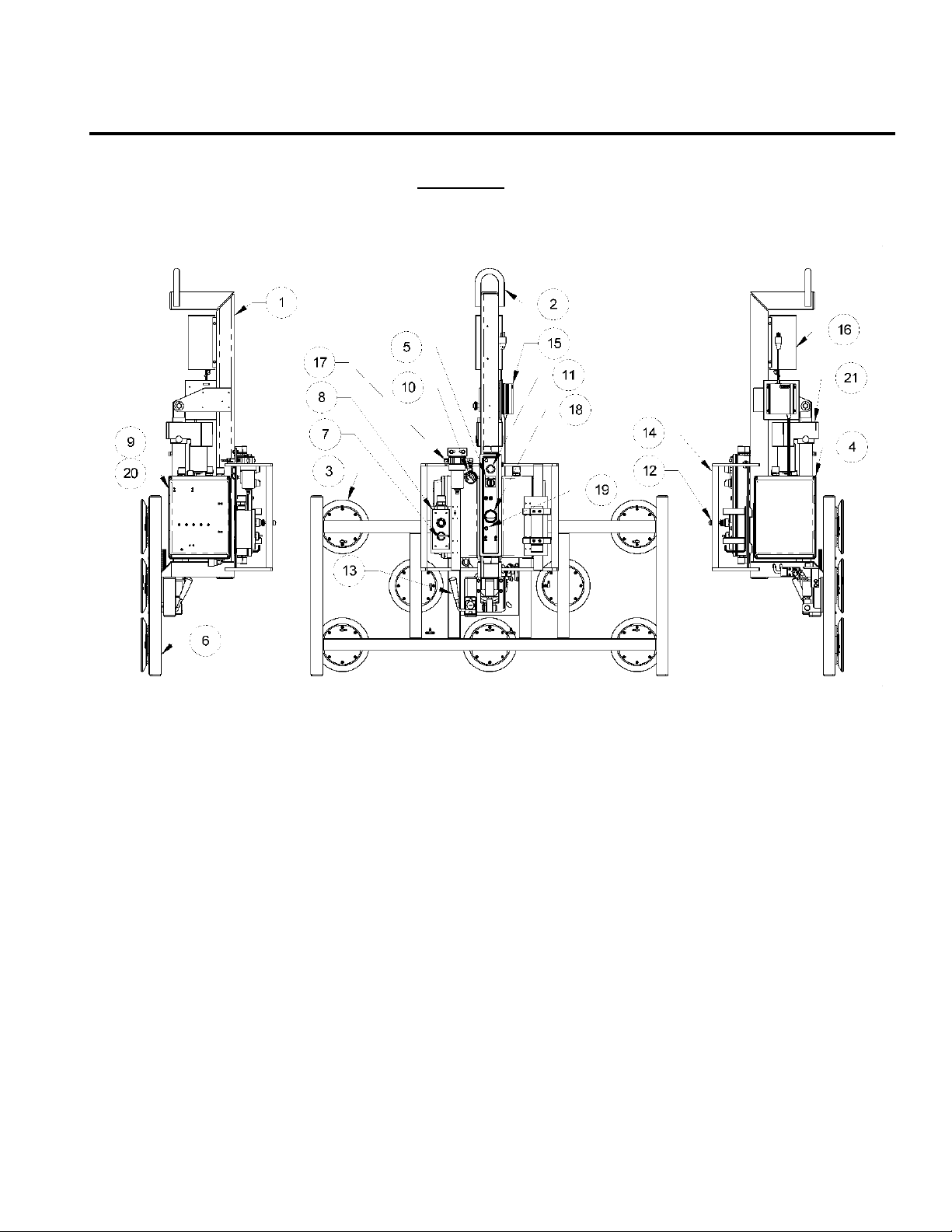

OPERATING FEATURES................................................................................................... 5

ASSEMBLY....................................................................................................................... 6

INTENDED USE ............................................................................................................... 7

LOAD CHARACTERISTICS ................................................................................................... 7

OPERATING ENVIRONMENT ................................................................................................ 8

DISPOSAL OF THE LIFTER................................................................................................... 8

OPERATION .................................................................................................................... 9

BEFORE USING THE LIFTER ................................................................................................ 9

Taking Safety Precautions ............................................................................................................................9

Performing Inspections and Tests .................................................................................................................9

TO APPLY THE PADS TO A LOAD ........................................................................................ 10

Powering up the Lifter................................................................................................................................10

Positioning the Lifter on the Load ...............................................................................................................10

Sealing the Pads against the Load...............................................................................................................10

Reading the Vacuum Gauge .......................................................................................................................11

Vacuum Level on Optimal Surfaces .............................................................................................................11

Vacuum Level on Other Surfaces ................................................................................................................11

TO LIFT AND MOVE THE LOAD........................................................................................... 12

Load Capacity and the Lift Light..................................................................................................................12

Monitoring Vacuum Indicators ....................................................................................................................12

Controlling the Lifter and Load....................................................................................................................12

In Case of Power Failure ............................................................................................................................13

TO ROTATE THE LOAD EDGEWISE ...................................................................................... 13

TO TILT THE LOAD .......................................................................................................... 13

TO RELEASE THE PADS FROM THE LOAD .............................................................................. 14

AFTER USING THE LIFTER ................................................................................................ 14

Storing the Lifter........................................................................................................................................14

MAINTENANCE.............................................................................................................. 15

INSPECTION SCHEDULE ................................................................................................... 15

Every-Lift Inspection ..................................................................................................................................15

Frequent Inspection ...................................................................................................................................15

Periodic Inspection ....................................................................................................................................15

Infrequent Use ..........................................................................................................................................16

TESTING SCHEDULE ........................................................................................................ 16

Operational Tests.......................................................................................................................................16

Load Test ..................................................................................................................................................16

MAINTENANCE SCHEDULE ................................................................................................ 17