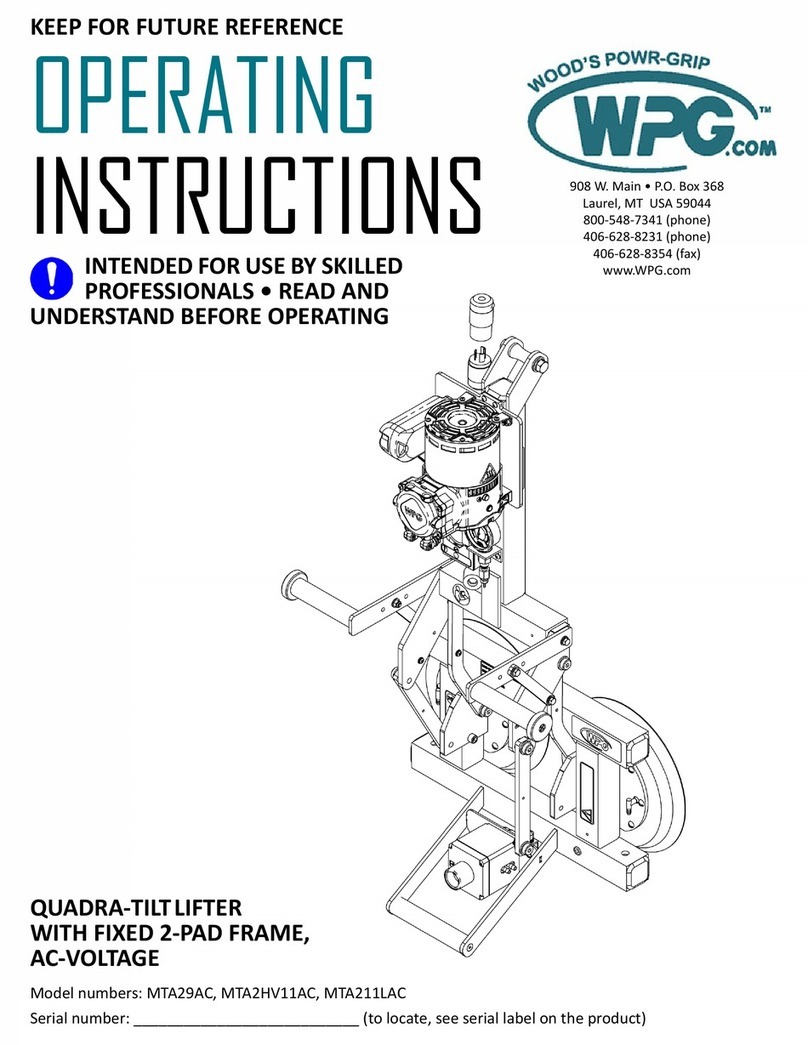

Product

Description

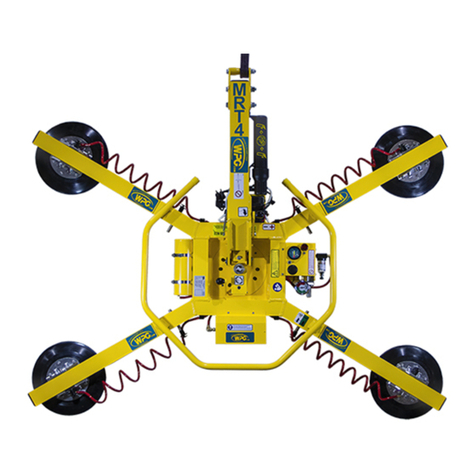

Designed for use with hoisting equipment, MRTA8-DC3 lifters support loads using vacuum and

manipulate loads using manual 360° rotation and mechanically assisted, manual 90° tilt motions.

Model Number MRTA811LDC3 MRTA810TDC3 MRTA810CDC3O

Vacuum Pads1

1...... Available with other rubber compounds for special purposes (see www.wpg.com).

(8 each, standard rubber)

11" [28 cm] nom. diameter,

lipped (Model G3370)

10" [25 cm] nom. diameter,

with ring (Model VPFS10T2

2...... Standard with replaceable sealing rings for rough or textured surfaces (see “REPLACEMENT PARTS”).

)

10" [25 cm] nom. diameter,

concave (Model G0750)

Pad Spread3

3...... The illustrations under “TOCHANGE THE PAD FRAME CONFIGURATION”show the Pad Spread and Maximum Load Capacity for all approved MRTA811LDC pad

frame configurations.

---------------------------- (to outer edges) ----------------------------

Length ‒Maximum 104¾" [266 cm] 104" [264 cm] 102½" [260 cm]

Length ‒Minimum 47" [119 cm] 46" [117 cm] 44¾" [114 cm]

Width‒Maximum 58¾" [149 cm] 58" [147 cm] 56½" [143 cm]

Width ‒Minimum 12½" [32 cm] 11½" [29 cm] 10" [26 cm]

Maximum Load

Capacity4

4...... The Maximum Load Capacity is rated at a vacuum of 16" Hg [-54 kPa] on clean, smooth, nonporous flat surfaces with a friction coefficient of 1. Pad

compound, load rigidity, strength, surface conditions, overhang, angle, center of gravity and temperature can also affect the lifting capacity. A “qualified

person” should evaluate the effective lifting capacity for each use (see definition under “Rated Load Test”).

Total with 4 Pads 320 kg 270 kg 270 kg

Total with 8 Pads 635 kg 545 kg 545 kg

Lifter

Weight 91 kg 87 kg 87 kg

Power System 12 volts DC, 5.5 amps

Battery Capacity 7 amp-hours

Rotation

Capability Manual, 360°, with latching at each ¼ turn (when required)

Tilt

Capability

Manual, 90°, with four-bar tilt linkage that provides mechanical advantage and tilt locks that prevent tilt

motion when engaged

Product

Options See separate instructions about options.

Operating

Elevation Up to 6,000' [1,828 m]

Operating

Temperatures 32° — 104° F [0° — 40° C]

Service Life 20,000 lifting cycles, when used and maintained as intended5

5...... Vacuum pads, filter elements and other wear-out items are excluded.

Software Version Intelli-Grip®7.6

Design

Standard

Compliant with AS 4991. Note: Each circuit of the Dual Vacuum System complies with the capacity

requirements of this Standard.

Rev 5.0/2-21 MRTA8-DC3: #35121AUS3

SPECIFICATIONS