Rev 4.0/7-20 MRT4-DC3: #35068AUS1

SPECIFICATIONS .....................................................................................3

SAFETY...................................................................................................5

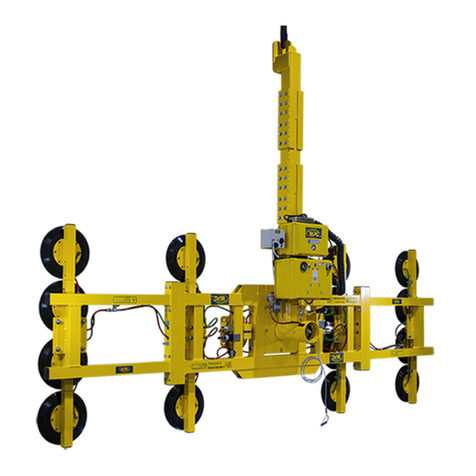

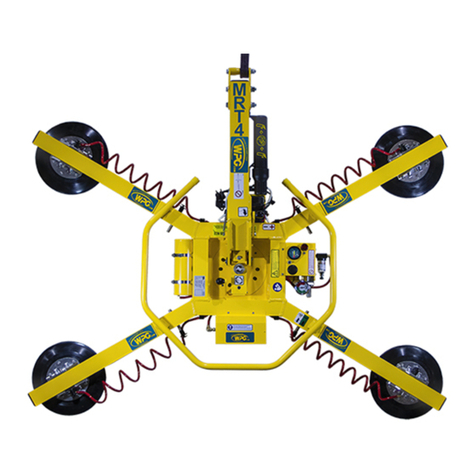

OPERATING FEATURES............................................................................6

ASSEMBLY..............................................................................................7

TOCHANGE THE PAD FRAME CONFIGURATION ..................................................9

Installing/Removing Extension Arms and Repositioning Vacuum Pads ............................10

Using Secondary Rotation Stops .......................................................................................11

INTENDED USE .....................................................................................12

LOAD CHARACTERISTICS...............................................................................12

OPERATING ENVIRONMENT..........................................................................13

DISPOSAL OF THE LIFTER .............................................................................13

OPERATION..........................................................................................14

BEFORE USING THE LIFTER...........................................................................14

Taking Safety Precautions .................................................................................................14

Selecting a Screen Language.............................................................................................14

Performing Inspections and Tests .....................................................................................15

Checking the 12-Volt Battery ............................................................................................15

TOATTACH THE PADS TO ALOAD ..................................................................16

Positioning the Lifter on the Load.....................................................................................16

Powering up the Lifter ......................................................................................................17

Sealing the Pads on the Load............................................................................................17

Reading the Vacuum Gauges ............................................................................................18

Interpreting the Lift Light..................................................................................................19

Watching Vacuum Indicators ............................................................................................19

Controlling the Lifter and Load .........................................................................................20

In Case of a Power Failure.................................................................................................20

TOROTATE THE LOAD .................................................................................21

TOTILT THE LOAD ......................................................................................22

TORELEASE THE PADS FROM THE LOAD .........................................................24

AFTER USING THE LIFTER.............................................................................25

Storing the Lifter ...............................................................................................................25

INSPECTIONS AND TESTS......................................................................27

INSPECTION SCHEDULE ................................................................................27

TABLE OF CONTENTS