Ergoswiss SL 14 Compact Series User manual

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 1of 32

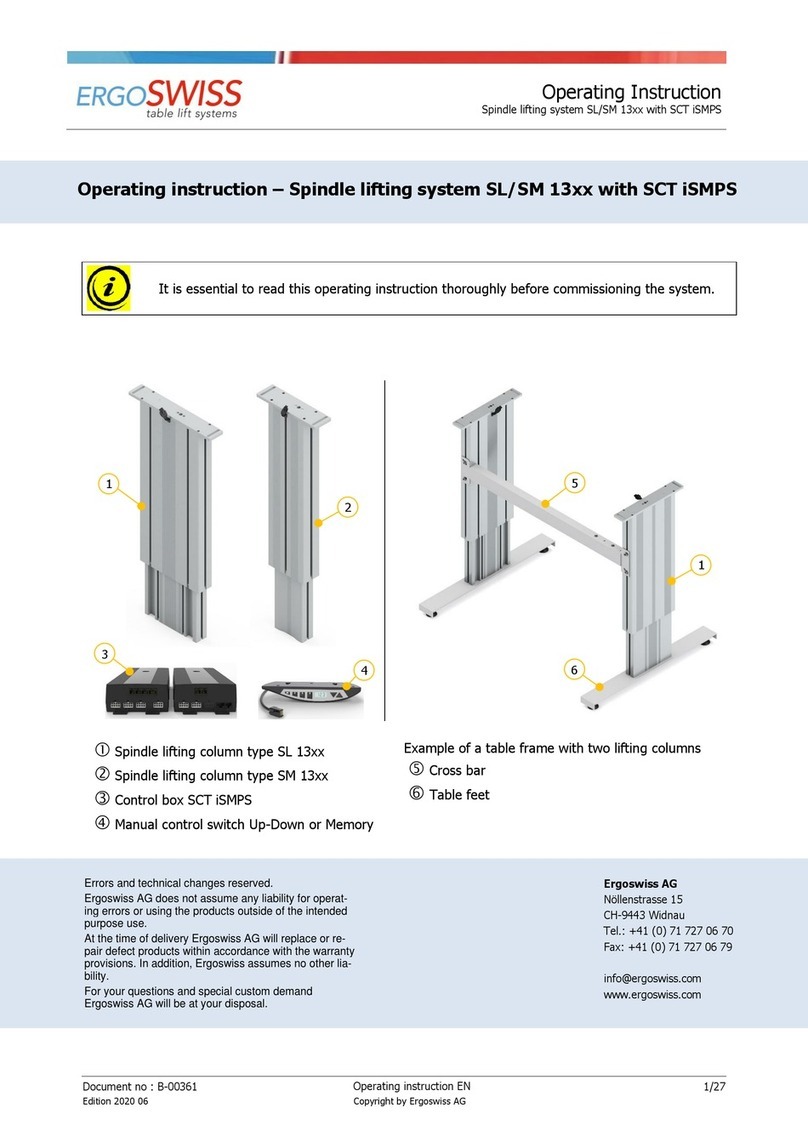

Operating instruction – Spindle lifting system SL/SK/SM 14xx

with SCT iSMPS 24V and Exchangeable battery

It is essential to read this operating instruction thoroughly before commissioning the system.

The manual must be kept in close proximity to the system for future reference.

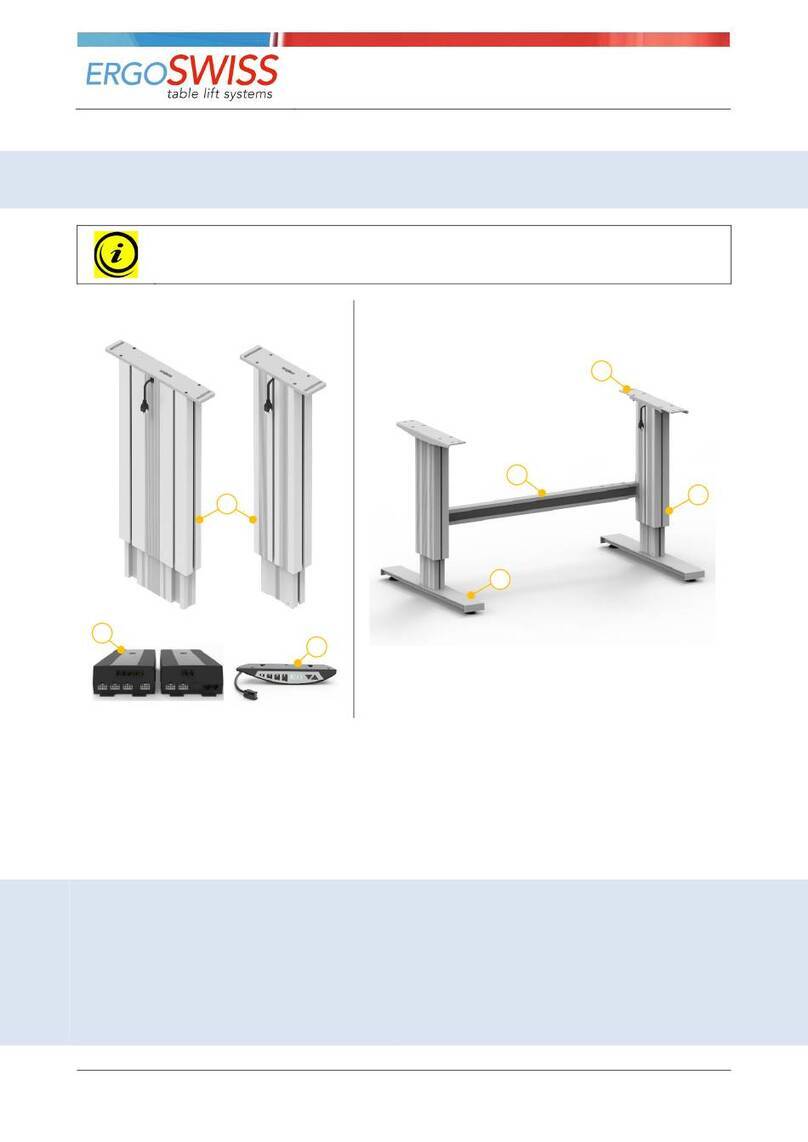

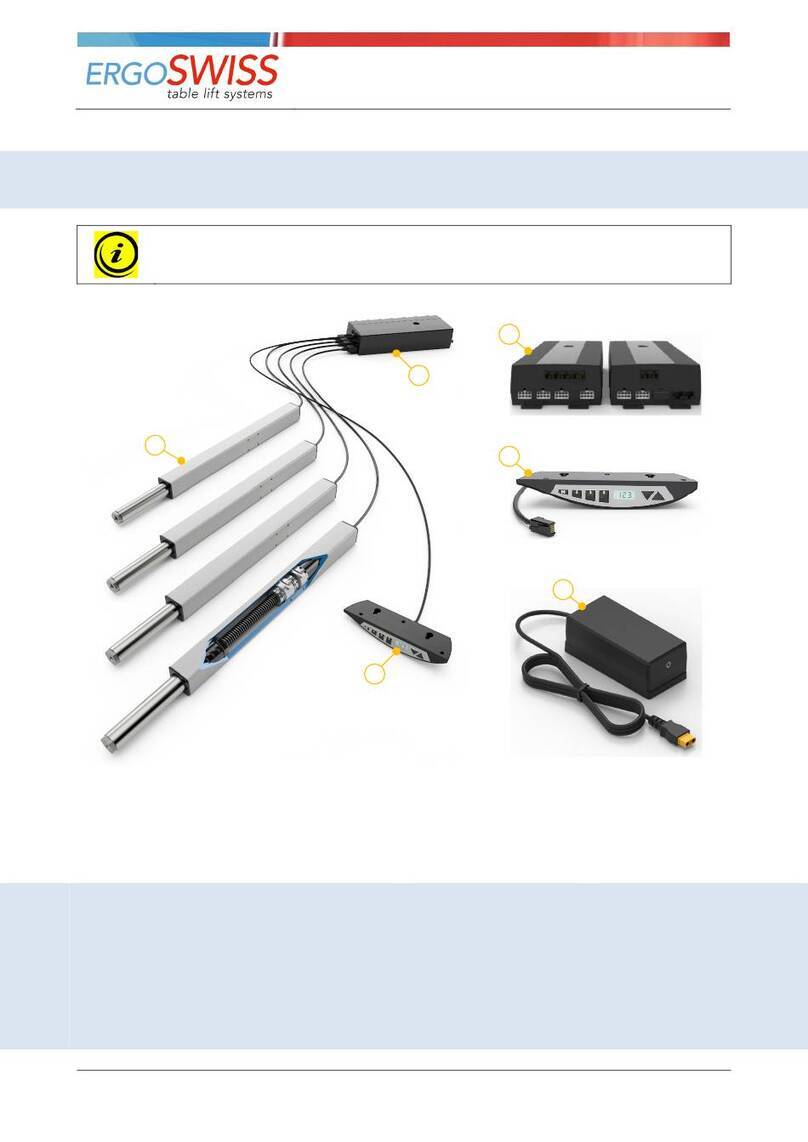

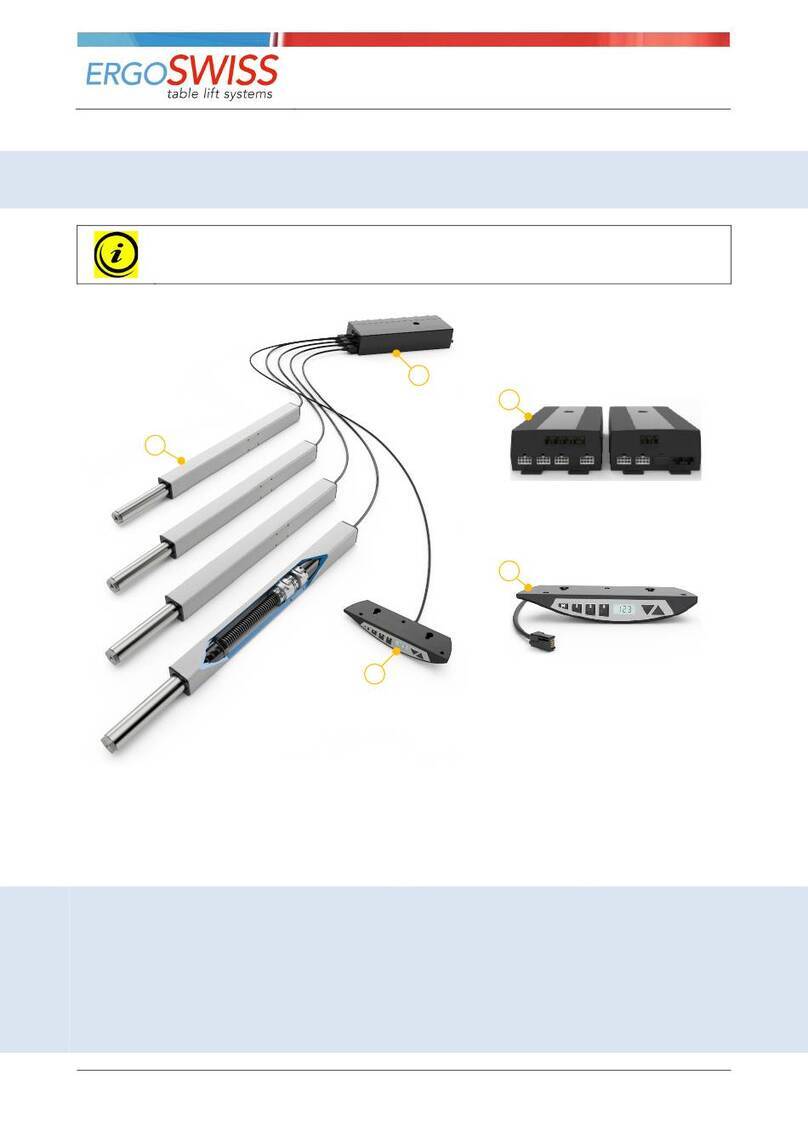

Spindle lifting column of Type SL, SK or SM

Control box SCT iSMPS 24V

Exchangeable battery 24V

Hand switch Memory

Example of a frame with two lifting columns:

Table plate support

Cross bar

Table feet

Errors and technical changes reserved.

Ergoswiss AG does not assume any liability for operating errors or

using the products outside of the intended purpose use.

At the time of delivery Ergoswiss AG will replace or repair defect

products within accordance with the warranty provisions.

In addition, Ergoswiss assumes no other liability.

For your questions and special custom demand Ergoswiss AG will

be at your disposal.

Ergoswiss AG

Nöllenstrasse 15

CH-9443 Widnau

Tel.: +41 (0) 71 727 06 70

Fax: +41 (0) 71 727 06 79

info@ergoswiss.com

www.ergoswiss.com

6

7

1

5

1

2

4

3

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 2of 32

This operating instruction applies to:

Lifting systems SL 14xx, SK 14xx and SM 14xx

with control box SCT iSMPS 24V and exchangeable battery

Example: Lifting system SL 2430 EU/CH 12 Battery (Article number: 901.21516)

Example: Lifting system SL 2440 EU/CH 12 Battery (Article number: 901.21517)

Description

Standard variations

SL

Type of lifting element

SL, SK, SM

2440

Number of lifting elements

1, 2

2440

Spindle pitch in mm

4 mm

2440

Stroke length in cm

30 cm, 40 cm

EU/CH

Country specific power cable

EU/CH, US

12

11 = Hand switch Up-Down ; 12 = Hand switch Memory

12

Battery

With exchangeable battery 10A

Battery

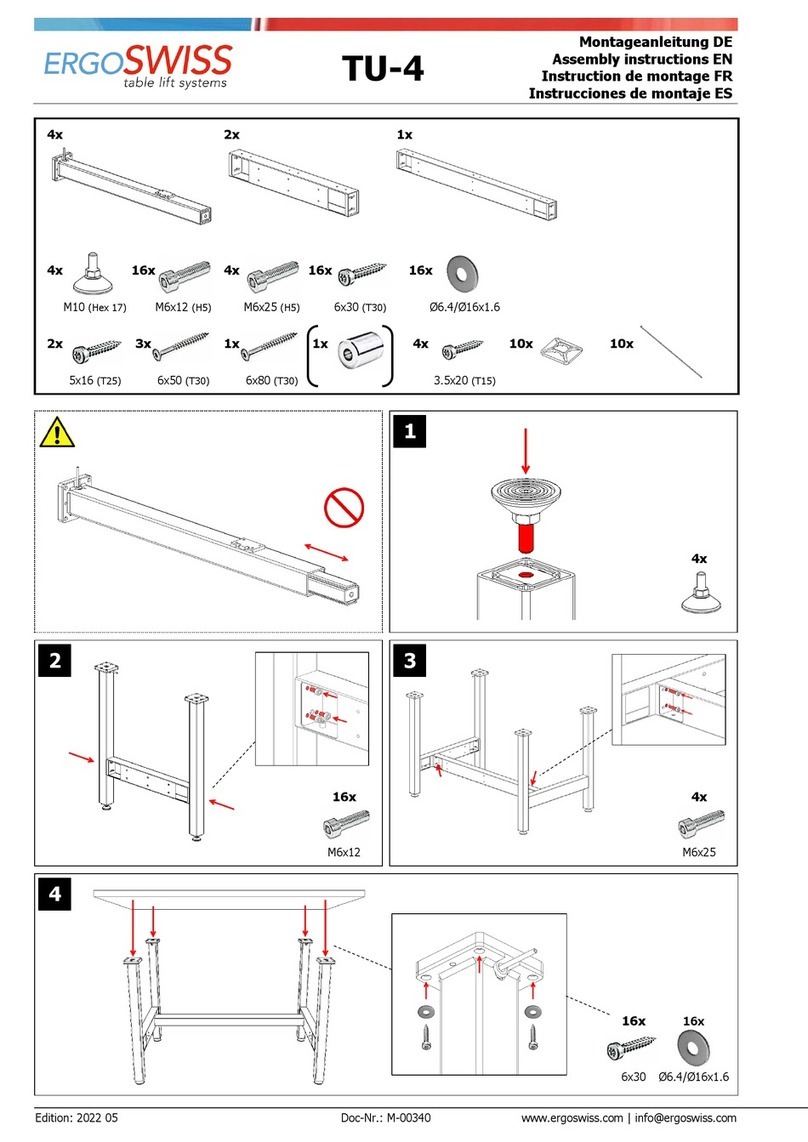

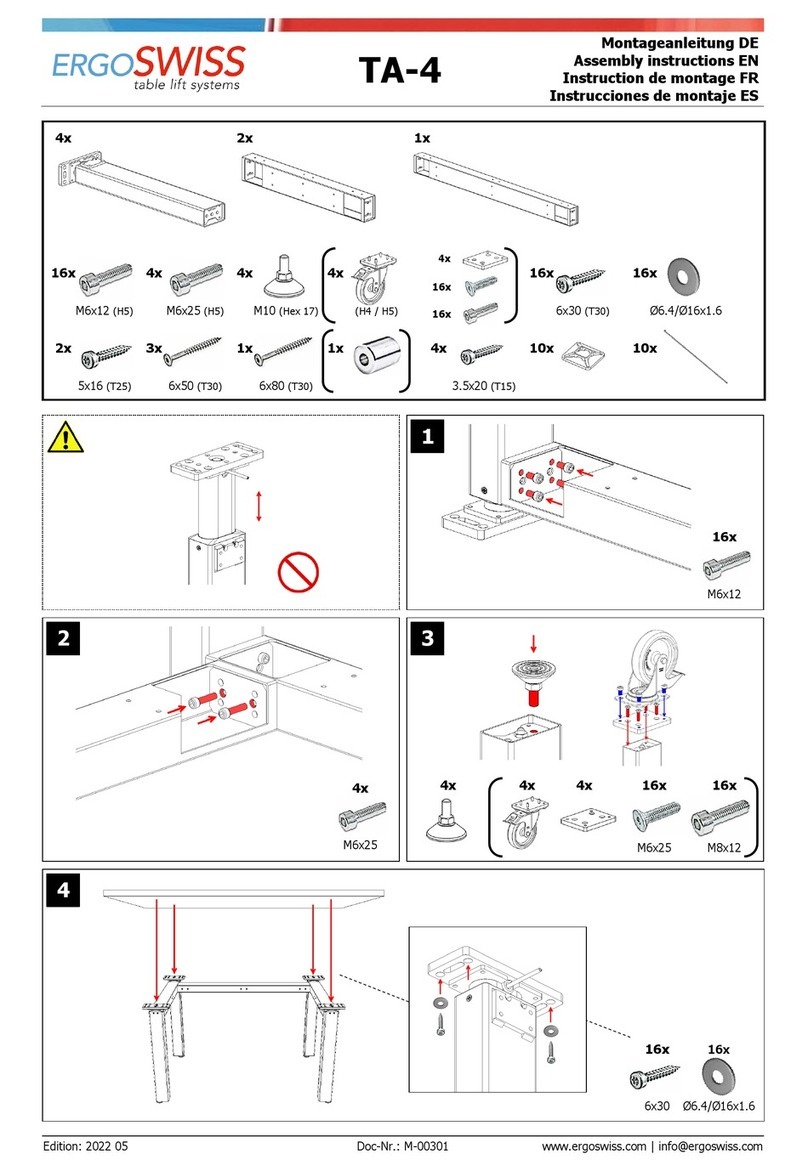

Frame SL 14xx, SK 14xx and SK 14xx

with control box SCT iSMPS 24V and exchangeable battery

Description

Standard variations

SL

Type of lifting element

SL, SK, SM

2440

Number of lifting elements

1, 2

2440

Spindle pitch in mm

4 mm

2440

Stroke length in cm

30 cm, 40 cm

960-1610

Distance from Center of leg to center of leg

Telescopic cross bar

EU/CH

Country specific power cable

EU/CH, US

12

11 = Hand switch Up-Down ; 12 = Hand switch Memory

12

Battery

With exchangeable battery 10A

Battery

Other versions

Description

ESD

Electrostatic discharge from external profile via inner profile

s01-s99

Special version: adapter plate, table foot, fitting length, color, etc.

Notes over the operating instruction:

Lifting systems from Ergoswiss AG are intended for installation in an overall system (e.g. assembly table)

and classified under the category of incomplete machines in accordance with the Machinery Directive

2006/42/EC.

This operating instruction contain information on the commissioning, handling and safety of the lifting sys-

tem and are aimed at the further- user and manufacturer of the entire system. The further-user of this lifting

system is obliged to create an operating manual with all usage information and hazard warnings for the en-

tire system.

The declaration of incorporation is only valid for the Ergoswiss lifting system and not for the overall system

created by the further-user.

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 3of 32

Table of content

1Safety requirements ................................................................................................................ 4

1.1 Explanations of the symbols and notes ..................................................................................... 4

2System description .................................................................................................................. 5

2.1 General .................................................................................................................................. 5

2.2 Intended purpose use ............................................................................................................. 5

2.2.1 General safety instructions................................................................................................... 6

2.3 Target group and prior knowledge ........................................................................................... 6

2.4 Handling the Lithium-Ion Battery Pack...................................................................................... 7

2.5 Performance characteristics ..................................................................................................... 8

2.5.1 Lifting column SL/SK/SM 14xx.............................................................................................. 8

2.5.2 Control box SCT4 iSMPS 24V ............................................................................................... 9

2.5.3 Hand switch Up/Down and Memory...................................................................................... 9

2.5.4 Exchangeable battery package........................................................................................... 10

2.5.5 System data ..................................................................................................................... 11

3Mounting instructions............................................................................................................ 12

3.1 Mounting instructions Lifting column ...................................................................................... 12

3.2 Mounting instructions Battery set ........................................................................................... 14

3.3 Mounting instructions Control box .......................................................................................... 16

3.4 Mounting instructions Hand switch ......................................................................................... 18

3.4.1 Hand switch Memory......................................................................................................... 18

3.4.2 Hand switch Up-Down ....................................................................................................... 18

4Initial operation..................................................................................................................... 19

4.1 Plug detection....................................................................................................................... 19

4.2 Duty cycle monitoring............................................................................................................ 19

5Operation with Hand switch Type Memory ........................................................................... 20

5.1 Drive Up / Down ................................................................................................................... 20

5.2 Saving and approaching a memory position ............................................................................ 20

5.3 Limit the stroke length (Container-Stop/Shelf-Stop)................................................................. 21

5.3.1 Limit upper end position - Shelf-Stop «S 04» ...................................................................... 21

5.3.2 Limit lower end position – Container-Stop «S 05» ............................................................... 21

5.4 Setting the shown height on the display «S 06»...................................................................... 22

5.5 Changing the displayed unit of measurement (cm/inch) «S 07» ............................................... 22

5.6 Deactivating / activating the tilt sensor «S 08» ....................................................................... 23

5.7 Locking the movement (child protection) ................................................................................ 24

5.8 Reference drive – Referencing the end positions ..................................................................... 25

5.9 Restore to factory settings – Factory reset «S 00» .................................................................. 26

6Operation with Hand switch Type Up-Down ......................................................................... 27

6.1 Up / Down............................................................................................................................ 27

6.2 Reference drive – Referencing the end positions ..................................................................... 27

7Safety strip – Squeezing protection ...................................................................................... 28

7.1 Commissioning...................................................................................................................... 28

8Maintenance and disposal ..................................................................................................... 29

8.1 Maintenance and cleaning ..................................................................................................... 29

8.2 Repairs and spare parts......................................................................................................... 29

8.3 Disassembly and disposal ...................................................................................................... 29

8.4 Electrical and Electronic Equipment Act .................................................................................. 29

9Error codes and trouble shooting .......................................................................................... 30

9.1 Error codes on the display ..................................................................................................... 30

9.2 Trouble shooting................................................................................................................... 31

10 Declaration of Incorporation ................................................................................................. 32

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 4of 32

1Safety requirements

The safety instructions must be paid attention to! If the system is operated improperly or not in accordance

with the intended use, there may be a risk to persons and property!

Before installing and operating the lifting system, this operating instruction must be read and understood.

The manual must be kept in the close proximity to the system for future reference.

1.1 Explanations of the symbols and notes

The following explanations of symbols and notes must be observed. These are classified according to ISO

3864-2 (ANSI Z535.4).

DANGER

Indicates an imminent danger.

Failure to follow the information will result in death or severe physical injury (disability).

WARNING

Indicates a potentially dangerous situation.

Failure to follow the information will result in death or severe physical injury (disability).

ATTENTION

Indicates a potentially dangerous situation.

Failure to follow the information will result in damage to property and minor or medium

physical injuries will result.

NOTE

Indicates general information, useful user tips and work recommendations, which have no im-

pact on the health and safety of staff.

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 5of 32

2System description

2.1 General

The basic functionality of a spindle lifting system SL/SK/SM by Ergoswiss AG is the lifting and lowering of

work surfaces, machine parts, profile systems, etc.

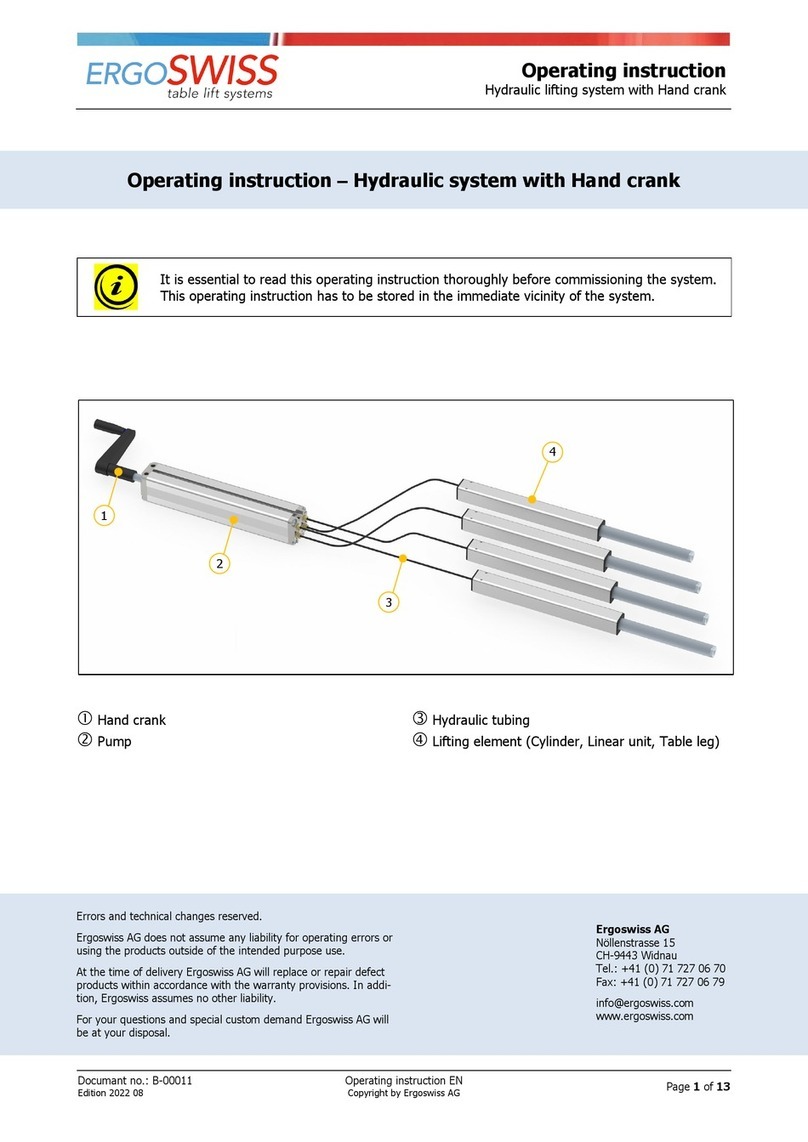

An operative spindle lifting System SL/SK/SM consists of a minimum of following components:

→Lifting column SL/SK/SM

→Control box SCT iSMPS 24V

→Hand switch Memory

→Exchangeable battery packet (Exchangeable battery 10A, holder, charging station)

The lifting column SL/SK/SM consists of two colorless anodized aluminium profiles which are guided with

plastic guides. The inner profile is moved by an inline spindle drive. Up to 4 spindle lifting elements can be

connected to one control box SCT4 iSMPS and be operated synchronously.

The high-performance control box SCT4 iSMPS 24V is equipped with four motor channels, which are ad-

justed synchronously by an encoder converter. Due to the optimised driving comfort, the end positions are

gently approached as low-speed zones up to the standstill. An integrated tilt sensor reacts to the system tip-

ping and can prevent potentially dangerous situations. Additional functions, such as the synchronisation of

two control boxes or the connection of safety strips (squeezing protection) can be used.

The control box is powered by the Exchangeable battery 10A. The maximum possible number of lifting cy-

cles depends on the status of the battery-lifespan and the system load. If the exchangeable battery 10A is

discharged, it must be removed from the holder and charged in the charging station.

The state of charge is indicated by four LEDs;

(1st LED = 25 % | 2nd LED = 50 % | 3rd LED = 75 % | 4th LED = 100 %).

With the hand switch Memory the lifting system can be operated comfortably, the work surface will be ad-

justed steplessly in its height.

The current height of the work surface is shown continuously on the display (in cm or inches). In addition,

up to three different memory positions can be saved and approached individually. Errors that occur are also

shown on the display.

2.2 Intended purpose use

Scope of application

NOT scope of application

→

Height adjustment of worktops

→

Height adjustment of machine parts

→

Height adjustment of profile systems

→

… the list is not exhaustive

→Clamping tool

→

Press (or counterhold for press)

→

Passenger transport

→

Security component

→

… the list is not exhaustive

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 6of 32

2.2.1 General safety instructions

ATTENTION

The safety instructions must be paid attention to! If the system is operated improperly or not

in accordance with the intended use, there may be a risk to persons and property!

The lifting system may be used if:

→it is located in closed rooms, in a dry and non-explosive environment.

→the ambient temperature is between +10 °C and +40 °C.

→the relative humidity range is between 30% and 70% (non-condensing).

→there are no strong electromagnetic fields nearby.

→This device can be used by children aged 8 and over and by persons with reduced physical, sensory or

mental abilities or lack of experience and knowledge if they are supervised or have been instructed in

the safe use of the device and the resulting dangers to understand.

The lifting system must not be:

→operated outside of the performance data (max. tensile, compressive, bending moment loads).

→subjected to impulse, impact and impact forces (e.g. setting down loads).

→operated with an incorrect mains voltage! Adhere to the type plate of the control box!

→designed for continuous operation (below the duty cycle ratio of 1/9).

→operated on unstable or sloping ground.

→operated with impermissible or non-designated components.

(e.g. different types of lifting elements; replacement of the control (control software))

→operated with damaged components.

→opened, reworked or rebuilt.

→operated if the power cable is not freely accessible. Disconnect the power cord in the event of a fault.

→Children must not play with the device. Cleaning and user maintenance shall not be made by children

without supervision.

When installing and operating the lifting system, the intended use of the entire system must be adhered to.

Commissioning is prohibited until the entire system complies with the provisions of the EC Directives

2006/42/EC (Machinery Directive). For this purpose, it is essential to perform a risk analysis, so that possible

residual hazards can be reacted to (e.g. through constructive measures or through instructions in the oper-

ating instructions and/or through safety indication on the system). In the event of improper use, the liability

of Ergoswiss AG and the general operating permit for the lifting system will expire.

2.3 Target group and prior knowledge

Before installing and operating the lifting system, this operating instruction must be read and understood.

The manual must be kept in close proximity to the system for future reference.

This operating instruction addresses the following groups of people:

The manufacturer of the overall system who integrates this lifting system into an overall system and

integrates these operating instructions into the operating instructions for the overall system.

The commissioning personnel who install the lifting system in a workplace, a machine, etc. and put it

into operation. For commissioning basic mechanical and electrical knowledge are required.

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 7of 32

2.4 Handling the Lithium-Ion Battery Pack

The exchangeable battery belongs to the class of portable batteries. As a rule, it works smoothly and

maintenance-free. At the end of its lifetime, the power becomes smaller and the exchangeable battery

should then be replaced.

Since the actual battery cells are surrounded by a plastic housing that also contains the charging electronics,

no changes to them can be detected from the outside. The housing also provides additional protection

against potentially leaked battery cells.

Disused exchangeable batteries, as well as old batteries made of power tools, garden tools and household

appliances (e.g. vacuum cleaner robots) are taken back by municipal collection points.

ATTENTION

Do not open the housing to remove the battery cells before disposal!

Don't try to replace used battery cells with new ones!

If the housing of the exchangeable battery is damaged in such a way, that damage to the contained battery

cells cannot be ruled out, it should be disposed of immediately. Preferably at the recycling centre and as a

precaution in such a way, that it can be received by employees. Talk to the specialist staff and point out the

damage.

Storage

Under no circumstances should you store the exchangeable battery in the refrigerator or water and not ex-

pose it to moisture. The storage temperature should be between 0 – 40 °C

(32 – 104 °F)

, whereby lower

temperatures are preferable. Due to self-discharge, recharging is required every 3 months.

Transport / Shipping

Lithium-ion batteries are classified as "dangerous goods" in international transport law. Thus, the regulations

for the transport of dangerous goods are relevant for them.

The following rules apply to the modes of transport:

•Road: ADR

Accord européen relatif au transport international des marchandises Dangereuses par Route.

(European Agreement on the International Carriage of Dangerous Goods by Road)

•Rail: RID

Règlement concernant le transport internaional ferr viare de marchandises Dangereuses

(Regulation on the international carriage of dangerous goods by rail)

•Sea freight: IMDG Code

International Maritime Code for Dangerous Goods

•Air freight: IATA DGR

International Air Transport Association Dangerous Goods Regulations

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 8of 32

2.5 Performance characteristics

2.5.1 Lifting column SL/SK/SM 14xx

Lifting column SL/SK 14xx

Lifting column SM 14xx

Cross-section

260 x 60 mm

(10.23” x 2.36”)

150 x 70 mm

(5.91” x 2.76”)

Standard stroke length

300, 400 mm (12”, 16”)

Installation length

Stroke length + 230 mm (9”)

Lower block position = stroke length + 227 mm (8.9”)

Weight

SL 1430 = 9.5 kg

(20.9 lbs)

SL 1440 = 10.9 kg

(24.0 lbs)

SK 1430 = 9.9 kg

(21.8 lbs)

SK 1440 = 11.3 kg

(24.9 lbs)

SM 1430 = 8.1 kg

(17.9 lbs)

SM 1440 = 9.2 kg

(20.3 lbs)

Max. allowed pressure

load

1’500 N

(337 lbf)

Max. allowed tensile load

FTensile stat. 500 N

(112 lbf)

; FTensile dyn. 50 N

(11 lbf)

Power consumption

5 A per lifting column (at maximum load)

Voltage

24 V

Lifting speed

6 – 7.5 mm/s

(0.24 – 0.3 ’’/s)

(load dependent)

Noise level

< 60 dBA

Protection class

(DIN EN 60529)

IP 30

Electrical connection Molex MiniFit plug 8 Pin

Cable length 1’800 m (71”)

End switch

No (reading Encoder)

Tested product life

5’000 cycles with 400 mm

(16’’)

stroke length

1’500 N

(337 lbf)

pressure load, duty cycle 1/9

dyn. = during the lifting movement

Duty Cycle 1/9; operating max. 1 min, pause 9 min

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 9of 32

Max. allowed bending moment

Lifting column SL/SK

Max. allowed bending moment

Lifting column SM

Mbxstat.

1’200 Nm

(885 lbf⋅ft)

Mbystat.

450 Nm

(332 lbf⋅ft)

Mbxdyn.

550 Nm

(406 lbf⋅ft)

Mbydyn.

200 Nm

(148 lbf

⋅

ft)

Mbxstat.

900 Nm

(664 lbf⋅ft)

Mbystat.

350 Nm

(258 lbf⋅ft)

Mbxdyn.

450 Nm

(332 lbf⋅ft)

Mbydyn.

150 Nm

(111 lbf

⋅

ft)

Mbx = force x stroke

Mby = force x stroke

Mbx = force x stroke

Mby = force x stroke

stat. = during standstill; dyn. = during stroke movement

2.5.2 Control box SCT4 iSMPS 24V

Dimension (L x B x H)

309 x 120 x 55 mm

(12.2” x 4.7” x 2.2”)

Weight

SCT4: 0.63 kg

(1.4 lbs)

Supply voltage

16.8 – 29 V DC (nominal 25.2 V)

10 A max. (nominal 3.0 A)

Primary standby power

< 0.6 W

Power

250 W ; 10 A @ 25 V DC

(Depending on power source)

Protection class (DIN EN 60529)

IP 20

Performance Level (DIN EN 13849-1)

PL b

2.5.3 Hand switch Up/Down and Memory

Electrical connection

RJ-12 plug 6 Pin

Cable length 2 m (79”)

Protection class (DIN EN 60529) IP 30

Stroke

Mbx

Force

Stroke

Mby

Force

Stroke

Force

Mbx

Stroke

Force

Mby

Bending moment of Lifting column SL/SK

F

orce

[N]

Stroke [mm]

F

orce

[N]

Stroke [mm]

Bending moment of Lifting column SM

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 10 of 32

2.5.4 Exchangeable battery package

Supply voltage

29 – 31 V DC

Supply current

250 mA; +/- 100 mA

Output power

250 W

Output voltage

16.8 – 29 V DC

nominal 25.2 V

Output

10 A (for ED 1/9

)

Short-term 20 A (only to absorb inrush currents)

Overcurrent shutdown 14 – 20 A

Capacity

6’000 mAh

Temperature (operating)

0 – 40 °C

(32 – 104 °F)

Temperature (storage)

0 – 55 °C

(32 – 131 °F)

Temperature (transport)

0 – 55 °C

(32 – 131 °F)

Relative humidity

(operation, transport and storage)

< 85%; non-condensing

Load

During charging, the LEDs (power indicator) flash

(1. LED = 25 % | 2. LED = 50 % | 3. LED = 75 % | 4. LED = 100 %).

Reload

The battery is self-discharging, therefore recharging is required every

3 months.

A full charge takes a maximum of 6h.

Overload

Charging is automatically terminated when:

- Voltage of the internal battery block is greater than 29 V +/- 3 V, or

- the voltage of a single cell is greater than 4.3 V.

The battery is fully charged when all 4 LEDs are green

Charge low

The battery warns with an acoustic signal if the voltage of the internal

battery block is less than 21 – 22 V.

The battery should then be charged.

Discharge

The battery will automatically shut down if:

- Voltage of internal battery blocks is less than 16.8 V +/-0.5 V, or

- Voltage of individual cells is less than 2.5 V

This state is called "battery discharged".

Further discharge is prevented.

This state is neither audible nor visually displayed and can only be ter-

minated by charging.

Overcurrent shutdown

When the output current reaches values between 14 A and 20 A, the

battery switches off immediately. When the output current is back in

the nominal range, the battery can be used again.

If necessary, this must be cooled and charged.

Short-circuit fuse

If a short circuit occurs at the output, the battery switches off immedi-

ately. When the short circuit has been eliminated, the battery can be

used again.

If necessary, the battery must be loaded

Duty Cycle 1/9; operating max. 1 min, pause 9 min

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 11 of 32

2.5.5 System data

# Lifting

elements

Max.

System

load

Stroke

length

Lifting

element

Control

type

# of cycles per load-

percentage at full

Battery charge

Lifting

speed

Duty

Cycle

[kg]

(lbs)

[mm]

(in)

Type

24 V

100%

50%

0%

[On/Off]

1 150

(330)

300

(12")

1430 Battery (V1991) 45 90 140

6 -

7.5 mm/s

(0.24

- 0.30 "/s)

Load dependent

1/9 min

400

(16")

1440 Battery (V1990) 35 70 110

2 300

(660)

300

(12")

1430 Battery (V1991) 30 50 80

400

(16")

1440 Battery (V1990) 25 40 60

Lifting column SL, SK or SM

The maximum number of cycles depends on the status of the battery-lifespan

Duty cycle 1/9; operating max. 1 min, pause 9 min

NOTE

The lifting system can be subjected to uneven loads as long …

→

the max. load on the single lifting element is not exceeded,

→

the max. bending torque of the lifting element is not exceeded,

→

the entire system is located on sufficient safe ground

… and the entire plant has been constructed in accordance with the provisions of the mechan-

ical equilibrium. Conducting a risk analysis

ATTENTION

High pulse / impact forces due to the discontinuation of loads are not allowed.

(e.g. discontinuation of loads in feed with crane or forklift)

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 12 of 32

3Mounting instructions

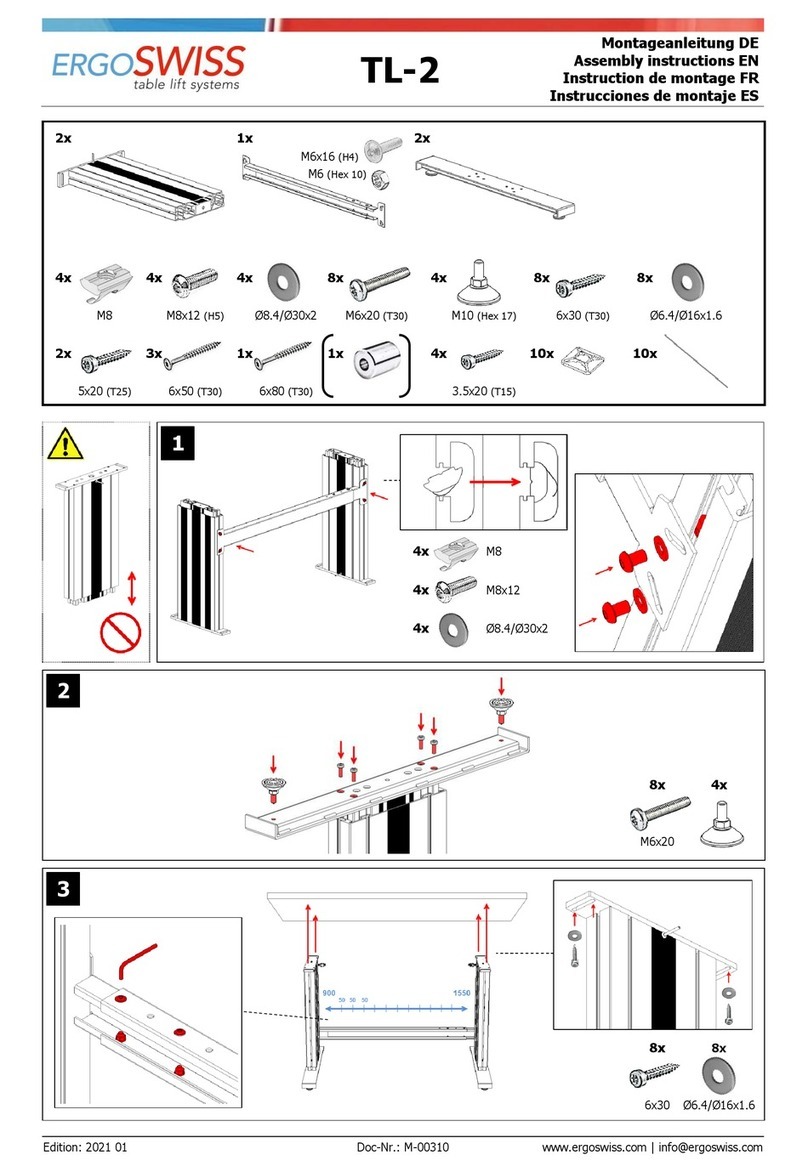

3.1 Mounting instructions Lifting column

NOTE

The lifting system must be mounted in such a way, that driving to the lower position is possi-

ble at any time.

Otherwise, no initial operating and reset of the system can be carried out.

Mounting on top

Adaptor plate with slot hole

(Screw size M8)

Mounting on T-slot (Cross bar)

Outer profile with T-slots

Mounting at bottom

Inner profile

4x Screw M6x20 self-tapping

(included in scope of delivery)

Motor cable 1’800 mm

(71’’)

With up to 5x Motor extension cable of 1’200 mm (47”)

can be extended up to 7’800 mm

(307”)

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 13 of 32

Lifting column Type SL/SK

Adaptor plate (Top)

2x Slot hole

for screw size M8

(drawing in mm)

Inner profile (Bottom)

4x Through hole

for screw size M6 (Ø5.3)

(Ø0.2”)

Torque max. 6 Nm

(4.4 lbf⋅ft)

Screw-in depth mind. 15 mm

(0.6”)

4x Screw M6x20 self-tapping included

in the scope of delivery

(drawing in mm)

Lifting column Type

SM

Adaptor plate (Top)

2x Slot hole

for screw size M8

(drawing in mm)

Inner profile (Bottom)

4x Through hole

for screw size M6 (Ø5.3)

(Ø0.2”)

Torque max. 6 Nm

(4.4 lbf⋅ft)

Screw-in depth mind. 15 mm

(0.6”)

4x Screw M6x20 self-tapping included

in the scope of delivery

(drawing in mm)

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 14 of 32

3.2 Mounting instructions Battery set

Exchangable battery 10 A

The charge status of the exchangable

battery can be checked using the 4

LEDs of power/charging indicator indi-

cator on the battery.

To check the charging status, press the

test button to the right of the LEDs.

From right to left the LEDs show 25 %,

50 %, 75 % and 100 % of charge.

(drawing in mm)

Holder for exchangable battery

2x Slot hole

for screw size M4 (Ø4.2)

(Ø0.16”)

Torque max. 2 Nm

(1.5 lbf⋅ft)

(e.g.: Button head screw DIN 7981-C,

Ø 3.5 mm (0.14”),head-Ø 6.9 mm (0.27’’))

Screws are not included in the scope of

delivery.

(drawing in mm)

Exchangable battery with Holder

The exchangable battery can be in-

serted into the holder.

If the exchangable battery is plugged into

the holder, the set is in operating status.

(drawing in mm)

NOTE

The mounting location provided for the holder should be easily accessible and chosen in such

a way so that …

→

the exchangeable battery can be easily removed and

→the LED power indicator can be read without removal.

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 15 of 32

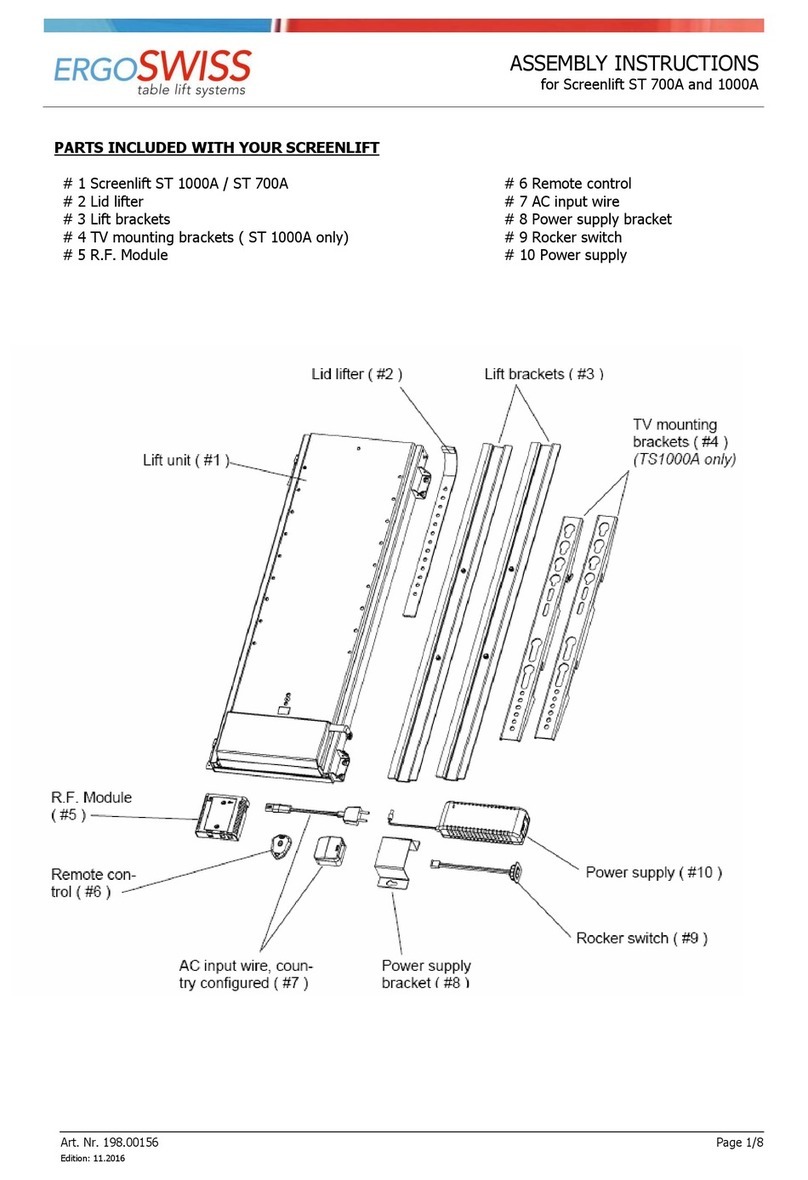

Docking station

The docking station can be connected

to the electricity using the country

specific charging cable.

A brand new battery must first be acti-

vated. This is done simply by plugging

the battery into the docking station.

After approx. 10 seconds, the

power/charging indicator starts to light

up green and the battery is being

charged.

The charge status of the exchangable

battery can be checked using the 4

LEDs of power/charging indicator indi-

cator on the battery.

To check the charging status, press the

test button to the right of the LEDs.

From right to left the LEDs show 25 %,

50 %, 75 % and 100 % of charge.

Only use the battery when it is fully

(100%) charged.

(drawing in mm)

ATTENTION

Der Akkupack darf nur mit der mitgelieferten Docking Station geladen werden!

Nur diese gewährleistet eine ausreichende Sicherheit.

The exchangable battery may only be charged with the included docking station!

This is the only way to ensure adequate security.

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 16 of 32

3.3 Mounting instructions Control box

ATTENTION

During mounting of the control box the power cable needs to be disconnected from the

mains!

NOTE

The control box has an integrated tilting sensor as standard. To ensure the smooth normal

operation, the control box must be fixed rigidly to the system before initial commissioning.

(e.g. below the tabletop)

Mounting the control box at the bottom of a tabletop:

1. Place the control box to the desired location and mark the drill holes with a pen.

2. Pre-drill 3 holes (Ø 2.5 mm /

0.1’’)

.

Be careful not to drill through the table top!

3. Mount the control box with 3 screws.

(e.g.: Button head screw DIN 7981-C, Ø 3.9 mm

(0.15”)

, head-Ø 7.5 mm (

0.33’’))

.

NOTE

When tightening the screws do not exceed a maximum torque of 2 Nm

(1.5 lbf⋅ft)

!

NOTE

The motor cable has a length of 1’800 mm

(71’’)

. If needed, up to 5 motor extension cables

can be connected. They have a length of 1’200 mm

(47’’)

each.

124.00137: Extension cable Motor SCT/Compact 1.2m

(47’’)

NOTE

The cable of the hand switch has a length of 1’800 mm

(71’’)

. If needed it can be expanded

with up to 3 extension cables. They have a length of 1’000 mm

(39’’)

each.

124.00290: Extension cable Hand switch SCT 1m

(39’’)

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 17 of 32

Control box SCT4 iSMPS 24V

ATTENTION

Connecting homemade products to the control box is prohibited!

Only use supplied components.

4. Connect the motor cables to the lifting columns.

5. Connect the motor cables to the control box in the correct order from 1to 4.

(Automatic plug detection on all sockets)

6. Connect the hand switch to the control box.

If necessary, optional components can now be connected (e.g. safety strips, sync cable).

7. Connect the Holder for exchangable battery to the control box.

NOTE

Before connecting the Exchangeable battery onto the Holder the following must be verified:

→ Does the mains voltage correspond to the value on the name plate of the control box?

→ Are the plugs of the motor cable connected to the correct sockets (1to 4)?

→ Is the entire lifting system assembled according to the assembly instructions?

8. Connect the Exchangeable battery onto the Holder.

Connection for Safety strip

Connection for Safety strip

Connection for Hand switch

Connection for Sync cable

Motor socket 1

Motor socket 2

Motor socket 3

Motor socket 4

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 18 of 32

3.4 Mounting instructions Hand switch

3.4.1 Hand switch Memory

1. Position the hand switch underneath the table plate.

The control panel must overhang below the work sur-

face!

2. Fasten the hand switch using the mounting screws.

Be careful not to drill through the table top!

3.4.2 Hand switch Up-Down

1. Position the hand switch underneath the table plate.

The control panel must overhang below the work sur-

face!

2. Fasten the hand switch using the mounting screws.

Be careful not to drill through the table top!

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 19 of 32

4Initial operation

ATTENTION

Danger of squeezing during height adjustment!

ATTENTION

It must be possible to fully retract the lifting element to its lower block position at any time

(also in the operating state).

If the lifting element cannot retract completely and hits a stop before it reached its lower

block position, the zero position is set incorrectly. This leads to a collision when moving up to

the upper block position.

ATTENTION

The system may only be fully loaded after the initial operation has been completed.

During the initial operation, the lifting system may be loaded with max. 50% of the system

load.

NOTE

During the initial operation, the lifting system drives with half the speed.

1. Keep the buttons and pressed simultaneously to drive the lower block position.

The system moves downwards at half speed. Upward movement is disabled.

2. After reaching the block position, the system will drive out a few millimeters.

Afterwards the control box will emit 3 signal sounds.

3. let go of the buttons and .

After reaching the block position, the lower and the upper position will be stored automatically.

The initial operation is completed.

NOTE

The lower position is 3 mm (0.12’’) higher than the block position. The upper position depends

on the lifting element type, resp. of the control box software.

4.1 Plug detection

The control box can detect whether a lifting element is plugged into the relevant socket.

The control box only recognizes during the lifting movement whether a lifting element has been removed.

After plugging out or replacing a lifting element the system must be reset to synchronize all connected lifting

elements.

4.2 Duty cycle monitoring

The duty cycle monitoring checks the ratio between the operation time and standstill time. To avoid over-

heating of the system a duty cycle of 1/9 (ON/OFF) should be maintained.

The maximum continuous operating time is 1 minutes. Afterwards a pause of at least 9 minutes needs to be

observed before the system can be operated again.

Operating instruction

Spindle lifting system SL/SK/SM 14xx

with SCT4 iSMPS 24V and Exchangeable battery

Document no.: B-00411

Edition 2024 02

Operating instruction EN

Copyright by Ergoswiss AG

Page 20 of 32

5Operation with Hand switch Type Memory

5.1 Drive Up / Down

This function is used for easy height adjustment of the system.

Press the button or .

Keep the button pressed until the desired working height is reached.

5.2 Saving and approaching a memory position

With this function it is possible to memorise a certain position/height and approach it at a later time by

pushing one button. With the 3 memory buttons up to 3 different positions can be stored and approached.

1. Drive to the desired position and press the button M3 times.

2. Press one of the buttons

1

2

3

within 5 seconds.

After saving the control box will emit 1 signal sound.

The memory position is now stored under the pressed button.

To approach a stored memory position:

Keep one of the buttons

1

2

3

pressed until the desired working height is reached.

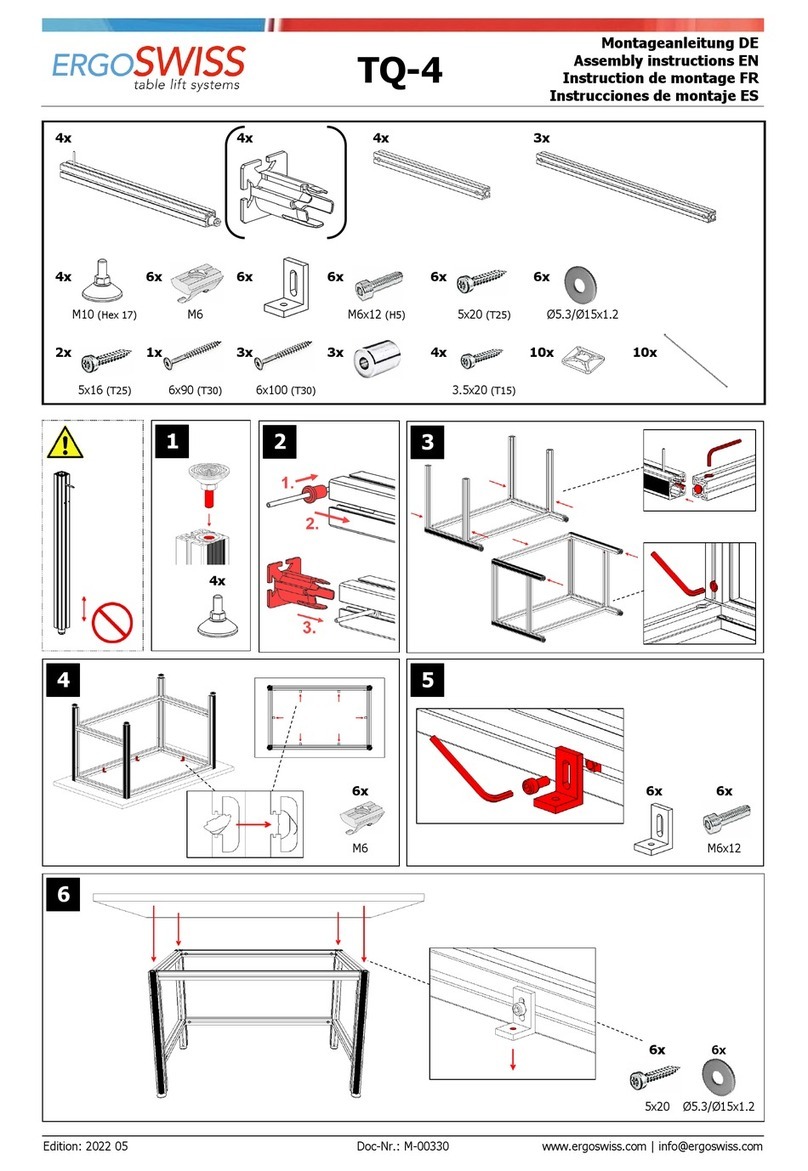

Other manuals for SL 14 Compact Series

1

This manual suits for next models

2

Table of contents

Other Ergoswiss Lifting System manuals

Ergoswiss

Ergoswiss TQ-4 User manual

Ergoswiss

Ergoswiss FC 650 3.0 User manual

Ergoswiss

Ergoswiss PA 2830 User manual

Ergoswiss

Ergoswiss SLA VD Series User manual

Ergoswiss

Ergoswiss SLA 13 Series User manual

Ergoswiss

Ergoswiss SL compact User manual

Ergoswiss

Ergoswiss SL 13 Series User manual

Ergoswiss

Ergoswiss SL 14 Compact Series User manual

Ergoswiss

Ergoswiss TL-2 User manual

Ergoswiss

Ergoswiss ST 700A User manual