8

Tool Specifications

Angle Grinder SWS 180 Power SWS 230 Power

Article number 702 496 X 702 498 X

Input power 2 500 W 2 500 W

Output power 1 700 W 1 700 W

No-load speed 8 500 RPM 6 600 RPM

Grinding disc dia. max. 180 mm max. 230 mm

Grinding disc thickness min. 1 mm, max. 10 mm min. 1 mm, max. 8 mm

Mounting hole 22.2 mm 22.2 mm

Weight approx. 5.4 kg approx. 5.4 kg

Safety class / II / II

Working safely with this machine is

possible only when the operating

and safety information are read

completely and the instructions con-

tained therein are strictly followed.

In addition, the general safety in-

structions in the enclosed booklet

must be followed.

If the cable is damaged or cut through

while working, do not touch the cable

but immediately pull the mains plug.

Never use the machine with a dam-

aged cable.

Wear protective goggles, ear protec-

tors and face mask.

Wear protective gloves and sturdy

shoes. When necessary, also wear an

apron.

When working with the machine, al-

ways hold it firmly with both hands

and provide for a secure stance.

❑For all work with the machine, the auxiliary han-

dle 6 and the protective guard 7 must be mounted.

❑Use only grinding tools whose allowable speed is

at least as high as the no-load speed of the ma-

chine.

❑Observe the dimensions for the grinding disc. The

mounting hole diameter must fit the centring flange

(square form part). Do not use reducer pieces or

adapters.

❑Check grinding tools before use. The grinding tool

must be properly mounted and turn freely. Perform

a test run for at least 30 seconds without load. Do

not use damaged, out of round or vibrating grind-

ing tools.

❑Do not clamp the machine in a vice.

❑Always direct the cable to the rear away from the

machine.

❑Clamp the workpiece in case it does not remain

stationary from its own weight.

❑When grinding metal, flying sparks are produced.

Take care that no persons are endangered. Be-

cause of the danger of fire, no combustible mate-

rials should be located in the vicinity (spark flight

zone).

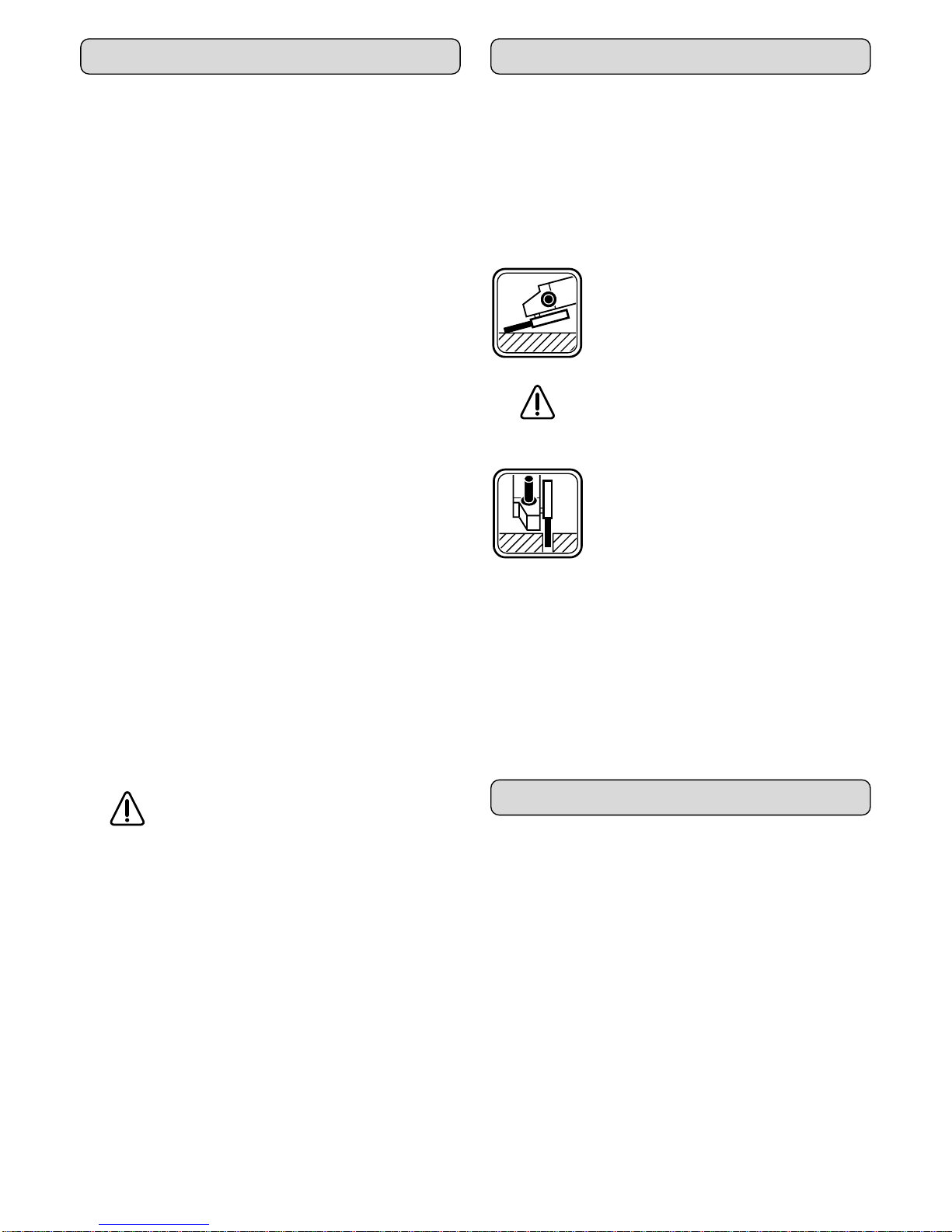

❑Apply the machine to the workpiece only when

switched on.

❑Always switch off the machine and allow to come

to a stop before putting down.

❑Keep hands away from rotating grinding tools.

❑Connect machines that are used in the open via a

residual current circuit breaker with a triggering

current of 30 mA maximum. Use only extension

cables that are intended for outdoor use and are

protected against splash water.

❑For the labelling of the machine, do not drill into

the housing or attach with rivets. The protective in-

sulation is then no longer ensured. Use stickers.

❑Use only original WÜRTH parts and accessories.

For your safety

GB

☞ For further notes on safety refer to enclosed Sheet